Abstract

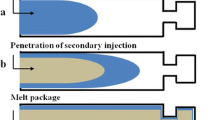

The relationship among the processing parameters, crystalline morphology, and macroscopic properties in injected molded bar becomes very complicated due to existence of temperature gradient and shear gradient along the sample thickness. To enhance the shear strength, gas-assisted injection molding (GAIM) was utilized in producing the molded bars. The aim of our research was to explore the relationship between processing conditions and the spatial variation of the hierarchy structure as well as the mechanical properties of high-density polyethylene (HDPE) obtained via GAIM. In our previous work [Wang L, Yang B, Yang W et al (2011) Colloid Polym Sci 289:1661–1671], we found that the enhancement of the gas pressure can remarkably increase the degree of molecular orientation in the HDPE samples, which turns out to improve the mechanical performances of GAIM parts. In this work, the hierarchy structure, orientation behavior, and mechanical properties of molder bars under different gas delay time were investigated using a variety of characterization techniques including rheological experiments, scanning electron microscope, tensile testing, differential scanning calorimetry, and two-dimensional wide-angle X-ray scattering. Moreover, the temperature field during the short shot stage of GAIM process was simulated using an enthalpy transformation approach. Our results indicate that these properties were intimately related to each other, and with prolonged gas delay time, GAIM samples with higher degree of orientation and improved mechanical properties were obtained.

Similar content being viewed by others

References

Michaeli W, Haberstroh E (2000) Kunststoffe Plast Eur 90:52–56

Avery J (2001) Gas-assist injection molding: principles and application. Hanser Publishers, Munich

Chen SH, Hu SY, Chao SM (2000) Polym Eng Sci 40:595–606

Haagh LGAAV, Peters GWM, Van de Vosse FN, Hmeijer HE (2001) Polym Eng Sci 41:449–465

Haberstroh E, Wehr H (2000) Macromol Mater Eng 284:76–80

Marcilla A, Odjo-Omoniyi A, Ruiz-Femenia R, Garcia-Quesada JC (2006) J Mater Process Technol 178:350–357

Liu SJ, Wu YC (2007) Polym Test 26:232–242

Shen YK, Jian HM, Wu WY, Yang SY (2001) Int Commun Heat Mass Transf 28:139–148

Johnson L, Olley P, Coates PD (2000) Plast Rubber Compos 29:31–37

Li CT, Isayev AI (2004) Polym Eng Sci 44:983–991

Chau SY (2008) Polym Eng Sci 48:1801–1814

Chang YP, Hu SY, Chen SC (1998) Int Commun Heat Mass Transf 25:989–998

Yang B, Fu XR, Yang W, Liang SP, Sun N, Hu S, Yang MB (2009) Macromol Mater Eng 294:336–344

Yang B, Fu XR, Yang W, Liang SP, Hu S, Yang MB (2009) Polym Eng Sci 49:1234–1242

Zheng GQ, Yang W, Yang MB, Chen JB, Li Q, Shen CY (2008) Polym Eng Sci 48:976–986

Zheng GQ, Huang L, Yang W, Yang B, Yang MB, Liu CT, Shen CY (2007) Polymer 48:5486–5492

Zhang K, Liu ZY, Yang B, Yang W, Lu Y, Wang L, Sun N, Yang MB (2011) Polymer 52:3871–3878

Zheng GQ, Yang W, Liu CT, Shen CY, Yang MB (2007) Mater Lett 61:3436–3439

Huang L, Yang W, Yang B, Yang MB, An HN (2008) Polymer 49:4051–4056

Wang L, Yang W, Huang L, Yang B, Sun N, Yang MB (2010) Plast Rubber Compos 39:385–391

Sun N, Yang B, Wang L, Yang W, Zhang K, Yang MB (2011) Polym Plast Technol 50:804–809

Chien RD, Chen SC, Jeng MC, Yang HY (1999) Polymer 40:2949–2959

Chen SC, Hu SY, Huang JS, Chien RD (1998) Polym Eng Sci 37:1085–1100

Ong NS, Lee HL, Parvez MA (2001) Adv Polym Technol 20:270–280

Parvez AZ, Ong NS, Lam YC, Tor SB (2002) J Mater Process Technol 121:27–35

Somania RH, Yang L, Zhu L, Hsiao BS (2005) Polymer 46:8587–8623

Keller A, Kolnaar HWH (1997) In: Meijer HEH (ed) Processing of polymers, vol 18. New York, VCH

Varga J, Karger-Kocsis J (1995) Polymer 36:4877–4881

Keller A, Cheng SZD (1998) Polymer 39:4461–4487

Goschel U, Swartjes FHM, Peters GWM, Meijer HEH (2000) Polymer 41:1541–1550

Somania RH, Yang L, Zhu L, Hsiao BS (2005) Polymer 46:8587–8623

Wang L, Yang B, Yang W, Sun N, Yin B, Feng JM, Yang MB (2011) Colloid Polym Sci 289:1661–1671

Alamo RG, Mandelkern L (1989) Macromolecules 22:1273–1277

Yang B, Fu XR, Yang W, Huang L, Yang MB, Feng JM (2008) Polym Eng Sci 48:1707–1717

Yang B, Fu XR, Yang W, Sun N, Hu S, Lu Y, Yang MB (2010) J Macromol Sci Part B, Phys 49:734–749

Carreau PJ, MacDonald IF, Bird RB (1968) Chem Eng Sci 23:901–911

Ko MJ, Waheed N, Lavine MS, Rutledge GC (2004) J Chem Phys 121:2823–2832

Su R, Su JX, Wang K, Yang CY, Zhang Q, Fu Q (2009) Eur Polym 45:747–756

Jose S, Aprem AS, Francis B et al (2004) Eur Polym J 40:2105–2115

Keum JK, Zuo F, Hsiao BS (2008) Macromolecules 41:4766–4776

Jiang ZY, Tang YJ, Rieger J et al (2002) Eur Polym J 46:1886–1904

Hermanns P, Platzek P (1939) Kolloid Z 88:68–72

Elmoumni A, Winter HH, Waddon A, Fruitwala H (2003) Macromolecules 36:6453–6461

Acknowledgment

This work is financially supported by the National Natural Science Foundation of China (grant nos. 20874066 and 51033003). The authors also thank Mr. Chao-liang Zhang for his kind assistance in morphological observations. In particular, Mr. Guo-qiang Pan from the NSRL of USTC is gratefully acknowledged for the 2d-WAXS experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, L., Yang, B., Sun, N. et al. Role of gas delay time on the hierarchical crystalline structure and mechanical property of HDPE molded by gas-assisted injection molding. Colloid Polym Sci 290, 1133–1144 (2012). https://doi.org/10.1007/s00396-012-2610-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-012-2610-5