Abstract

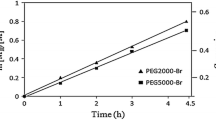

In this study, we formed grafted polystyrene (PS) brushes possessing nanocluster structures through atom transfer radical polymerization from initiator cores presented on Si surfaces that had been generated using reactive ion etching (RIE). We established the surface grafting polymerization kinetics of the nanoclustered PS chains on the Si surfaces to fit their experimentally determined thickness (ellipsometry) and number-average molecular weight (M n) of “free” PS (gel permeation chromatography). The propagation rate (k p) and active grafting species deactivation rate (k d) were obtained from reactions involving styrene concentrations from 0.2 to 2 M. We also used scanning electron microscopy to observe the morphologies of the PS grafted to the surfaces after various reaction times at various styrene concentrations. The PS brushes grafted onto the Si surfaces under styrene concentrations of 0.2, 0.5, 1, and 2 M exhibited clustered structures having cluster diameters of 12, 28, 42, and 45 nm, respectively; from these observations, we calculated the critical grafting density. In addition, we generated highly dense, well-defined patterns of PS on patterned Si(100) surfaces through the use of a very-large-scale integration process involving electron beam lithography and RIE. We employed the RIE system to generate a high density of reactive species at the bottom of the trenches for graft polymerization. After 21 h of grafting, AFM imaging revealed dense line patterns of nanoclustered PS.

Similar content being viewed by others

References

Stoykovich MP, Müller M, Kim SO, Solak HH, Edwards EW, de Pablo JJ, Nealey PF (2005) Science 308:1442–1446

Yu CJ, Gao H, Yu HY, Jiang HQ, Cheng GJ (2009) Appl Phys Lett 95:091108

Chen J-K, Li J-Y (2010) Appl Phys Lett 97:063701

Ozbay E (2006) Science 311:189–193

Chen J-K, Li J-Y (2010) Sens Actuators B 150:314–320

Chen J-K, Zhuang A-L (2010) J Phys Chem C 114:11801–11809

Ber S, Kose GT, Hasirci V (2005) Biomaterials 26:1977–1986

Chen JK, Chan CH, Chang FC (2008) Appl Phys Lett 92:053108

Gang Lu, Li Yi-Min, Chun-Hua Lu, Zhong-Zi Xu (2010) Colloid Polym Sci 288:1445–1455

Chan CH, Chen JK, Chang FC (2008) Sens Actuators B 13:327–332

Chen JK, Hsieh CY, Huang CF, Li PM, Kuo SW, Chang FC (2008) Macromolecules 41:8729–8736

Kuckling D (2009) Colloid Polym Sci 287:881–891

Mahajan N, Lu R, Wu S-T, Fang J (2005) Langmuir 21:3132–3135

Kim P, Lee SE, Jung HS, Lee HY, Kawai T, Suh K (2006) Lab Chip 6:54–59

Paul KE, Prentiss M, Whitesides GM (2003) Adv Funct Mater 13:259–263

Husemann M, Mecerreyes D, Hawker CJ, Hedrick JL, Shah R, Abbott NL (1999) Angew Chem Int Ed 38:647–649

Ahn SJ, Kaholek M, Lee W-K, LaMattina B, LaBean TH, Zauscher S (2004) Adv Mater 16:2141–2145

Kaholek M, Lee W-K, LaMattina B, Caster KC, Zauscher S (2004) Nano Lett 4:373–378

Werne TAV, Germack DS, Hagberg EC, Sheares VV, Hawker CJ, Carter KRJ (2003) Am Chem Soc 125:3831–3838

Xu FJ, Zhong SP, Yung LYL, Kang ET, Neoh KG (2004) Biomacromolecules 5:2392–2403

Kizhakkedathu JN, Norris-Jones R, Brooks DE (2004) Macromolecules 37:734–743

Ma H, Hyun J, Stiller P, Chilkoti A (2004) Adv Mater 16:338–341

Iwata R, Suk-In P, Hoven VP, Takahara A, Akiyoshi K, Iwasaki Y (2004) Biomacromolecules 5:2308–2314

Anderson DG, Burdick JA, Langer R (2004) Science 305:1923–1924

Husemann M, Morrison M, Benoit D, Frommer J, Mate CM, Hinsberg WD, Hedrick JL, Hawker CJJ (2000) Am Chem Soc 122:1844–1845

Zhou F, Jiang L, Liu W, Xue Q (2004) Macromol Rapid Commun 25:1979–1983

Chen JK, Chen ZY, Lin HC, Hong PD, Chang FC (2009) ACS Appl Mater Interfaces 1:1525–1532

Chen J-K, Hsieh C-Y, Huang C-F, Li P-MJ (2009) Colloid Interface Sci 338:428–434

Shi YJ, Li XM, Tong L, Toukabri R, Eustergerling B (2008) Phys Chem Chem Phys 10:2543–2551

Chen ZY, Chen JK (2011) Colloid Polym Sci 289:433–445

Chen J-K, Chen T-YJ (2011) Colloid Interface Sci 355:359–367

Wasserman SR, Tao Y-T, Whitesides GM (1989) Langmuir 5:1074–1087

Watanabe H, Kilbey SM II, Tirrell M (2000) Macromolecules 33:9146–9151

Acknowledgment

We thank the National Nano Device Laboratory for financially supporting the electron beam lithography equipment used in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, JK., Zhuang, AL. Patterning nanocluster polystyrene brushes grafted from initiator cores on silicon surfaces by lithography processing. Colloid Polym Sci 289, 1283–1294 (2011). https://doi.org/10.1007/s00396-011-2450-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-011-2450-8