Abstract

Fluid-flow devices with low dissipation, but large contact area, are of importance in many applications. A well-known strategy to design such devices is multi-scale topology optimization (MTO), where optimal microstructures are designed within each cell of a discretized domain. Unfortunately, MTO is computationally very expensive since one must perform homogenization of the evolving microstructures, during each step of the optimization process. Furthermore, methods to impose a desired contact area have not been pursued in MTO. Here, we propose a graded multiscale topology optimization for minimizing the dissipation in fluid-flow devices, subject to a desired contact area. Several pre-selected, but size-parameterized and orientable microstructures are chosen; their constitutive tensors and contact areas are pre-computed at a finite number of sizes. Then, during optimization, a simple interpolation is used to significantly reduce the computation while retaining many of the benefits of MTO. The algorithm allows for continuous switching between microstructures during optimization, but prevents mixing through penalization. The optimization is carried out using a neural network (NN) since: (1) the NN implicitly guarantees the partition of unity, i.e., ensures that the net volume fraction of microstructures in each cell is unity, (2) the number of design variables is only weakly dependent of the number of microstructure used, (3) it supports automatic differentiation, thereby eliminating manual sensitivity analysis, and (4) one can perform topology optimization at a coarser scale, and then extract a high-resolution design via a simple post-processing step. Several numerical results are presented to illustrate the proposed framework.

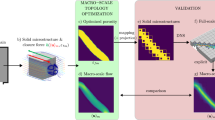

Graphical abstract

Given a set of candidate microstructures and a fluid topology optimization problem, a neural network (NN) selects appropriate microstructures, optimizes their size and orientation to produce a graded multi-scale design.

Similar content being viewed by others

References

Sigmund O, Maute K (2013) Topology optimization approaches: a comparative review. Struct Multidiscip Optim 48(6):1031–1055

Alexandersen J, Andreasen CS (2020) A review of topology optimisation for fluid-based problems. Fluids 5(1):29

Borrvall T, Petersson J (2003) Topology optimization of fluids in stokes flow. Int J Numer Methods Fluids 41(1):77–107

Nagrath S, Lecia V, Sequist SM, Bell DW, Irimia D, Ulkus L, Smith MR, Kwak EL, Digumarthy S, Muzikansky A et al (2007) Isolation of rare circulating tumour cells in cancer patients by microchip technology. Nature 450(7173):1235–1239

Hugh Fan Z, Mangru S, Granzow R, Heaney P, Ho W, Dong Q, Kumar R (1999) Dynamic dna hybridization on a chip using paramagnetic beads. Anal Chem 71(21):4851–4859

Hayes MA, Polson NA, Phayre AN, Garcia AA (2001) Flow-based microimmunoassay. Anal Chem 73(24):5896–5902

Jiang G, Jed Harrison D (2000) mrna isolation in a microfluidic device for eventual integration of cdna library construction. Analyst 125(12):2176–2179

Liu Y-J, Guo S-S, Zhang Z-L, Huang W-H, Baigl D, Xie M, Chen Y, Pang D-W (2007) A micropillar-integrated smart microfluidic device for specific capture and sorting of cells. Electrophoresis 28(24):4713–4722

Jin-Woo C, Oh KW, Thomas JH, Heineman WR, Halsall BH, Nevin JH, Helmicki AJ, Henderson Thurman H, Ahn CH (2002) An integrated microfluidic biochemical detection system for protein analysis with magnetic bead-based sampling capabilities. Lab Chip 2(1):27–30

Zhu Y, Antao DS, Zhengmao L, Somasundaram S, Zhang T, Wang EN (2016) Prediction and characterization of dry-out heat flux in micropillar wick structures. Langmuir 32(7):1920–1927

Guo D, Alan JH, McGaughey JG, Fedder GK, Lee M, Yao S-C (2013) Multiphysics modeling of a micro-scale Stirling refrigeration system. Int J Therm Sci 74:44–52

Moran M, Wesolek D, Berhane B, Rebello K (2004) Microsystem cooler development. In: 2nd international energy conversion engineering conference, p 5611

Gregory D, Bixler BB (2012) Bioinspired rice leaf and butterfly wing surface structures combining shark skin and lotus effects. Soft Matter 8(44):11271–11284

Gregory D, Bixler BB (2013) Fluid drag reduction and efficient self-cleaning with rice leaf and butterfly wing bioinspired surfaces. Nanoscale 5(17):7685–7710

Huang X, Wang J, Li T, Wang J, Min X, Weixing Yu, El Abed A, Zhang X (2018) Review on optofluidic microreactors for artificial photosynthesis. Beilstein J Nanotechnol 9(1):30–41

Li L, Chen R, Liao Q, Zhu X, Wang G, Wang D (2014) High surface area optofluidic microreactor for redox mediated photocatalytic water splitting. Int J Hydrogen Energy 39(33):19270–19276

Lauder GV, Wainwright DK, Domel AG, Weaver JC, Wen L, Bertoldi K (2016) Structure, biomimetics, and fluid dynamics of fish skin surfaces. Phys Rev Fluids 1(6):060502

Evans HB, Gorumlu S, Aksak B, Castillo L, Sheng J (2016) Holographic microscopy and microfluidics platform for measuring wall stress and 3d flow over surfaces textured by micro-pillars. Sci Rep 6(1):1–12

Wu T (2019) Topology optimization of multiscale structures coupling fluid, thermal and mechanical analysis. Ph.D. thesis, Purdue University Graduate School

Jun W, Ole S, Groen JP (2021) Topology optimization of multi-scale structures: a review. Struct Multidiscip Optim 63(3):1455–1480

Zhou S, Li Q (2008) Design of graded two-phase microstructures for tailored elasticity gradients. J Mater Sci 43(15):5157–5167

Challis VJ, Guest JK (2009) Level set topology optimization of fluids in Stokes flow. Int J Numer Methods Eng 79(10):1284–1308

Allan G-H, Ole S, Haber RB (2005) Topology optimization of channel flow problems. Struct Multidiscip Optim 30(3):181–192

Guest JK, Prévost JH (2006) Topology optimization of creeping fluid flows using a Darcy–Stokes finite element. Int J Numer Methods Eng 66(3):461–484

Wiker N, Klarbring A, Borrvall T (2007) Topology optimization of regions of Darcy and Stokes flow. Int J Numer Methods Eng 69(7):1374–1404

Pereira A, Talischi C, Paulino GH, Menezes IFM, Carvalho MS (2016) Fluid flow topology optimization in polytop: stability and computational implementation. Struct Multidiscip Optim 54(5):1345–1364

Suárez MAA, Romero JS, Pereira A, Menezes IFM (2022) On the virtual element method for topology optimization of non-Newtonian fluid-flow problems. In: Engineering with computers, pp 1–22

Allaire G, Bonnetier E, Francfort G, Jouve F (1997) Shape optimization by the homogenization method. Numer Math 76:27–68

Allaire G, Kohn RV (1993) Optimal design for minimum weight and compliance in plane stress using extremal microstructures. Eur J Mech A Solids 12(6):839–878

Groen JP, Sigmund O (2018) Homogenization-based topology optimization for high-resolution manufacturable microstructures. Int J Numer Methods Eng 113(8):1148–1163

Coelho PG, Fernandes PR, Guedes JM, Rodrigues HC (2008) A hierarchical model for concurrent material and topology optimisation of three-dimensional structures. Struct Multidiscip Optim 35:107–115

Xia L, Breitkopf P (2014) Concurrent topology optimization design of material and structure within fe2 nonlinear multiscale analysis framework. Comput Methods Appl Mech Eng 278:524–542

Guest JK, Prévost JH (2007) Design of maximum permeability material structures. Comput Methods Appl Mech Eng 196(4–6):1006–1017

Guest JK, Prévost JH (2006) Optimizing multifunctional materials: design of microstructures for maximized stiffness and fluid permeability. Int J Solids Struct 43(22–23):7028–7047

Dede EM, Zhou Y, Nomura T (2020) Inverse design of microchannel fluid flow networks using Turing pattern dehomogenization. Struct Multidiscip Optim 62(4):2203–2210

Zhou Y, Lohan DJ, Zhou F, Nomura T, Dede EM (2022) Inverse design of microreactor flow fields through anisotropic porous media optimization and dehomogenization. Chem Eng J 435:134587

Jakšić Z, Jakšić O (2020) Biomimetic nanomembranes: an overview. Biomimetics 5(2):24

Nguyen CHP, Choi Y (2021) Multiscale design of functionally graded cellular structures for additive manufacturing using level-set descriptions. Struct Multidiscip Optim 64(4):1983–1995

Zhao R, Zhao J, Wang C (2022) Stress-constrained multiscale topology optimization with connectable graded microstructures using the worst-case analysis. Int J Numer Methods Eng 123(8):1882–1906

Zheng L, Kumar S, Kochmann DM (2021) Data-driven topology optimization of spinodoid metamaterials with seamlessly tunable anisotropy. Comput Methods Appl Mech Eng 383:113894

Wang L, Tao S, Zhu P, Chen W (2021) Data-driven topology optimization with multiclass microstructures using latent variable gaussian process. J Mech Des 143(3):1–35

Wang L, van Beek A, Da D, Chan Y-C, Zhu P, Chen W (2022) Data-driven multiscale design of cellular composites with multiclass microstructures for natural frequency maximization. Compos Struct 280:114949

Seth W, William A, Jun K, Tortorelli DA, White DA (2019) Simple, accurate surrogate models of the elastic response of three-dimensional open truss micro-architectures with applications to multiscale topology design. Struct Multidiscip Optim 60(5):1887–1920

White DA, Arrighi WJ, Kudo J, Watts SE (2019) Multiscale topology optimization using neural network surrogate models. Comput Methods Appl Mech Eng 346:1118–1135

Wang Y, Hang X, Pasini D (2017) Multiscale isogeometric topology optimization for lattice materials. Comput Methods Appl Mech Eng 316:568–585

Chandrasekhar A, Sridhara S, Suresh K (2022) Gm-tounn: graded multiscale topology optimization using neural networks. arXiv preprint arXiv:2204.06682

Li D, Dai N, Tang Y, Dong G, Zhao YF (2019) Design and optimization of graded cellular structures with triply periodic level surface-based topological shapes. J Mech Des 141(7):1–13

Sanders ED, Aguiló MA, Paulino GH (2018) Multi-material continuum topology optimization with arbitrary volume and mass constraints. Comput Methods Appl Mech Eng 340:798–823

Geng D, Wei C, Liu Y, Zhou M (2022) Concurrent topology optimization of multi-scale cooling channels with inlets and outlets. Struct Multidiscip Optim 65(8):234

Takezawa A, Zhang X, Kato M, Kitamura M (2019) Method to optimize an additively-manufactured functionally-graded lattice structure for effective liquid cooling. Addit Manuf 28:285–298

Takezawa A, Zhang X, Kitamura M (2019) Optimization of an additively manufactured functionally graded lattice structure with liquid cooling considering structural performances. Int J Heat Mass Transf 143:118564

Xu L, Cheng G (2018) Two-scale concurrent topology optimization with multiple micro materials based on principal stress direction. In: Advances in structural and multidisciplinary optimization: Proceedings of the 12th World congress of structural and multidisciplinary optimization (WCSMO12) 12. Springer, pp 1726–1737

Liu Z, Xia L, Xia Q, Shi T (2020) Data-driven design approach to hierarchical hybrid structures with multiple lattice configurations. Struct Multidiscip Optim 61(6):2227–2235

Wang Y, Kang Z (2019) Concurrent two-scale topological design of multiple unit cells and structure using combined velocity field level set and density model. Comput Methods Appl Mech Eng 347:340–364

Zhou H, Zhu J, Wang C, Zhang Y, Wang J, Zhang W (2022) Hierarchical structure optimization with parameterized lattice and multiscale finite element method. Struct Multidiscip Optim 65(1):1–20

Alexandersen J, Lazarov BS (2015) Topology optimisation of manufacturable microstructural details without length scale separation using a spectral coarse basis preconditioner. Comput Methods Appl Mech Eng 290:156–182

Andreasen CS (2011) Multiscale topology optimization of solid and fluid structures. DTU Technical University of Denmark Mechanical Engineering, Delhi

Popov P, Efendiev Y, Qin G (2009) Multiscale modeling and simulations of flows in naturally fractured karst reservoirs. Commun Comput Phys 6(1):162

Laptev V (2003) Numerical solution of coupled flow in plain and porous media. Ph.D. thesis, Technische Universität Kaiserslautern

Aziz E-S, Chassapis C, Esche S, Dai S, Xu S, Jia R (2008) Online wind tunnel laboratory. In: 2008 annual conference and exposition, pp 13–949

Mohammed MG, Messerman AF, Mayhan BD, Trauth KM (2016) Theory and practice of the hydrodynamic redesign of artificial hellbender habitat. Herpetol Rev 47(4):586–591

Balbi V, Ciarletta P (2013) Morpho-elasticity of intestinal villi. J R Soc Interface 10(82):20130109

Mohammed Ameen M, Peerlings RHJ, Geers MGD (2018) A quantitative assessment of the scale separation limits of classical and higher-order asymptotic homogenization. Eur J Mech A Solids 71:89–100

Erik Andreassen and Casper Schousboe Andreasen (2014) How to determine composite material properties using numerical homogenization. Comput Mater Sci 83:488–495

Lang PS, Paluszny A, Zimmerman RW (2014) Permeability tensor of three-dimensional fractured porous rock and a comparison to trace map predictions. J Geophys Res Solid Earth 119(8):6288–6307

Vianna RS, Cunha AM, Azeredo RBV, Leiderman R, Pereira A (2020) Computing effective permeability of porous media with fem and micro-ct: an educational approach. Fluids 5(1):16

Kumar T, Sridhara S, Prabhune B, Suresh K (2021) Spectral decomposition for graded multi-scale topology optimization. Comput Methods Appl Mech Eng 377:113670

Chandrasekhar A, Suresh K (2021) Tounn: topology optimization using neural networks. Struct Multidiscip Optim 63(3):1135–1149

Chandrasekhar A, Suresh K (2021) Multi-material topology optimization using neural networks. Comput Aided Des 136:103017

Rahaman N, Baratin A, Arpit D, Draxler F, Lin M, Hamprecht F, Bengio Y, Courville A (2019) On the spectral bias of neural networks. In: International conference on machine learning. PMLR, pp 5301–5310

Tancik M, Srinivasan P, Mildenhall B, Fridovich-Keil S, Raghavan N, Singhal U, Ramamoorthi R, Barron J, Ng R (2020) Fourier features let networks learn high frequency functions in low dimensional domains. Adv Neural Inf Process Syst 33:7537–7547

Chandrasekhar A, Suresh K (2022) Approximate length scale filter in topology optimization using Fourier enhanced neural networks. Comput Aided Des 150:103277

Maas AL, Hannun AY, Ng AY et al (2013) Rectifier nonlinearities improve neural network acoustic models. In: Proceedings of icml. Atlanta, Georgia, USA, vol 30, p 3

Bertsekas DP (2014) Constrained optimization and Lagrange multiplier methods. Academic Press, New York

Liu DC, Nocedal J (1989) On the limited memory BFGS method for large scale optimization: Mathematical programming, Springer 45(1-3):503–528

Chandrasekhar A, Sridhara S, Suresh K (2021) Auto: a framework for automatic differentiation in topology optimization. Struct Multidiscip Optim 64(6):4355–4365

Paszke A, Gross S, Massa F, Lerer A, Bradbury J, Chanan G, Killeen T, Lin Z, Gimelshein N, Antiga L, Desmaison A, Kopf A, Yang E, DeVito Z, Raison M, Tejani A, Chilamkurthy S, Steiner B, Fang L, Bai J, Chintala S (2019) Pytorch: an imperative style, high-performance deep learning library. In: Wallach H, Larochelle H, Beygelzimer A, d’ Alché-Buc F, Fox E, Garnett R (eds) Advances in neural information processing systems 32. Curran Associates, Inc., pp 8024–8035

Glorot X, Bengio Y (2010) Understanding the difficulty of training deep feedforward neural networks. In: Proceedings of the thirteenth international conference on artificial intelligence and statistics. JMLR workshop and conference Proceedings, pp 249–256

Ioffe S, Szegedy C (2015) Batch normalization: accelerating deep network training by reducing internal covariate shift. In: International conference on machine learning. pmlr, pp 448–456

Sigmund O, Petersson J (1998) Numerical instabilities in topology optimization: a survey on procedures dealing with checkerboards, mesh-dependencies and local minima. Struct Optim 16(1):68–75

Nocedal J, Wright SJ (1999) Numerical optimization. Springer, Berlin

DeSalvo GJ, Swanson JA (1979) ANSYS engineering analysis system: user’s manual. Swanson Analysis Systems, Houston

Ghasemi A, Elham A (2020) A novel topology optimization approach for flow power loss minimization across fin arrays. Energies 13(8):1987

Liang X, Li A, Rollett AD, Zhang YJ (2022) An isogeometric analysis-based topology optimization framework for 2d cross-flow heat exchangers with manufacturability constraints. Eng Comput 38(6):4829–4852

Dilgen SB, Dilgen CB, Fuhrman DR, Sigmund O, Lazarov BS (2018) Density based topology optimization of turbulent flow heat transfer systems. Struct Multidiscip Optim 57(5):1905–1918

Foret P, Kleiner A, Mobahi H, Neyshabur B (2020) Sharpness-aware minimization for efficiently improving generalization. arXiv preprint arXiv:2010.01412

Acknowledgements

The authors would like to thank the support of National Science Foundation through Grant Directorate for Engineering (CMMI 1561899). The authors acknowledge Subodh Subedi for helping with the 3D printing.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Replication of results

The Python code pertinent to this paper is available at (github.com/UW-ERSL/FluTO).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rahul Kumar Padhy and Aaditya Chandrasekhar contributed equally.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Padhy, R.K., Chandrasekhar, A. & Suresh, K. FluTO: Graded multi-scale topology optimization of large contact area fluid-flow devices using neural networks. Engineering with Computers 40, 971–987 (2024). https://doi.org/10.1007/s00366-023-01827-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-023-01827-6