Abstract

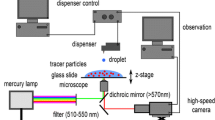

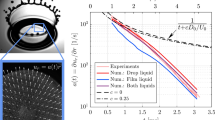

An experimental study is performed on high-acceleration separation of Newtonian liquid films trapped between two parallel plates. The test apparatus is capable of accelerating one plate at up to 325 m/s2 relative to a stationary substrate. Plates with average roughness up to 86 µm were studied. High-speed laser induced fluorescence (LIF) is used to determine the instantaneous film thickness distribution during the separation process. Two flow regimes exist in the film. As the gap between the substrates increases, a viscous fingering regime occurs along the perimeter of the wetted area, where air fingers grow radially inward. If the growth rate of those fingers is slow relative to the growth rate of the gap, a second regime exists in the center of the wetted region, in which cavitation bubbles emerge and grow. Once the two substrates are sufficiently separated, the liquid bridges connecting the two substrates break. At high accelerations, the separation ratio (the relative amount of fluid remaining on the moving substrate) is a nonlinear function of the surface roughness, liquid viscosity, and separation acceleration, and varies in the range between 35 and 55%. The separation ratio is strongly correlated with the relative areas of the fluid that are subject to viscous fingering and liquid cavitation. The LIF measurements show that the thickness of the residual layer remaining on each portion of the substrate depends on whether the substrate has been subject to viscous fingering or cavitation, and this observation explains qualitatively the measured differences in separation ratio.

Graphical abstract

Similar content being viewed by others

Availability of data and materials

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Anjos PHA, Dias EO, Miranda JA (2017) Inertia-induced dendriticlike patterns in lifting Hele-Shaw flows. Phys Rev Fluids 2:014003. https://doi.org/10.1103/PhysRevFluids.2.014003

Bai S-E, Shim J-S, Lee C-H et al (2014) Dynamic effect of surface contact angle on liquid transfer in a low speed printing process. Jpn J Appl Phys 53:05HC05. https://doi.org/10.7567/JJAP.53.05HC05

Bai L, Yan J, Zeng Z, Ma Y (2020) Cavitation in thin liquid layer: a review. Ultrason Sonochem 66:105092. https://doi.org/10.1016/j.ultsonch.2020.105092

Balu B, Berry AD, Hess DW, Breedveld V (2009) Patterning of superhydrophobic paper to control the mobility of micro-liter drops for two-dimensional lab-on-paper applications. Lab Chip 9:3066–3075. https://doi.org/10.1039/B909868B

Brennen CE (2013) Cavitation and bubble dynamics. Cambridge University Press, New York

Brulin S (2021) Hydrodynamic investigations of rapidly stretched liquid bridges. Ph.D. Thesis, Technische Universität Darmstadt

Brulin S, Roisman IV, Tropea C (2020a) Fingering instability of a viscous liquid bridge stretched by an accelerating substrate. J Fluid Mech. https://doi.org/10.1017/jfm.2020.422

Brulin S, Tropea C, Roisman IV (2020b) Pinch-off of a viscous liquid bridge stretched with high Reynolds numbers. Colloids Surf A Physicochem Eng Asp 587:124271. https://doi.org/10.1016/j.colsurfa.2019.124271

Chadov AV, Yakhnin ED (1979) Investigation of the transfer of aliquid from one solid surface to another. 1. Slow transfer. method of approximate calculation. Kolloidn Zh 41:817–820

Chen H, Tang T, Amirfazli A (2015a) Fast liquid transfer between surfaces: breakup of stretched liquid bridges. Langmuir 31:11470–11476. https://doi.org/10.1021/acs.langmuir.5b03292

Chen H, Tang T, Amirfazli A (2015b) Effects of surface wettability on fast liquid transfer. Phys Fluids 27:112102. https://doi.org/10.1063/1.4934961

Chen H, Tang T, Zhao H et al (2016) How pinning and contact angle hysteresis govern quasi-static liquid drop transfer. Soft Matter 12:1998–2008. https://doi.org/10.1039/C5SM02451J

Chen J, Wang P, Li M et al (2021) Rupture distance and shape of the liquid bridge with rough surface. Miner Eng 167:106888. https://doi.org/10.1016/j.mineng.2021.106888

Creton C, Ciccotti M (2016) Fracture and adhesion of soft materials: a review. Rep Prog Phys 79:046601. https://doi.org/10.1088/0034-4885/79/4/046601

Deplace F, Carelli C, Mariot S et al (2009) Fine tuning the adhesive properties of a soft nanostructured adhesive with rheological measurements. J Adhes 85:18–54. https://doi.org/10.1080/00218460902727381

Dias EO, Miranda JA (2013) Determining the number of fingers in the lifting Hele-Shaw problem. Phys Rev E 88:043002. https://doi.org/10.1103/PhysRevE.88.043002

Dodds S, Carvalho MS, Kumar S (2009) Stretching and slipping of liquid bridges near plates and cavities. Phys Fluids 21:092103. https://doi.org/10.1063/1.3212963

Eisner T, Aneshansley DJ (2000) Defense by foot adhesion in a beetle (Hemisphaerota cyanea). PNAS 97:6568–6573. https://doi.org/10.1073/pnas.97.12.6568

Federle W, Riehle M, Curtis ASG, Full RJ (2002) An integrative study of insect adhesion: mechanics and wet adhesion of pretarsal pads in ants1. Integr Comp Biol 42:1100–1106. https://doi.org/10.1093/icb/42.6.1100

Flanagan J, Schütze P, Dunne C et al (2020) Use of a blast coating process to promote adhesion between aluminium surfaces for the automotive industry. J Adhes 96:580–601. https://doi.org/10.1080/00218464.2018.1486713

Gorb SN (1998) The design of the fly adhesive pad: distal tenent setae are adapted to the delivery of an adhesive secretion. Proc Biol Sci 265:747–752. https://doi.org/10.1098/rspb.1998.0356

Huang W-X, Lee S-H, Sung HJ et al (2008) Simulation of liquid transfer between separating walls for modeling micro-gravure-offset printing. Int J Heat Fluid Flow 29:1436–1446. https://doi.org/10.1016/j.ijheatfluidflow.2008.07.002

James DF, Pouran M (2009) Droplet formation in quickly stretched liquid filaments. Rheol Acta 48:611–624. https://doi.org/10.1007/s00397-009-0356-x

Kang HW, Sung HJ, Lee T-M et al (2008) Liquid transfer between two separating plates for micro-gravure-offset printing. J Micromech Microeng 19:015025. https://doi.org/10.1088/0960-1317/19/1/015025

Krebs FC (2009) Fabrication and processing of polymer solar cells: a review of printing and coating techniques. Sol Energy Mater Sol Cells 93:394–412. https://doi.org/10.1016/j.solmat.2008.10.004

Li S, Lowengrub JS, Fontana J, Palffy-Muhoray P (2009) Control of viscous fingering patterns in a radial Hele-Shaw cell. Phys Rev Lett 102:174501. https://doi.org/10.1103/PhysRevLett.102.174501

Lindner A, Derks D, Shelley MJ (2005) Stretch flow of thin layers of Newtonian liquids: fingering patterns and lifting forces. Phys Fluids 17:072107. https://doi.org/10.1063/1.1939927

McDonald JD, Kerekes RJ (2018) Rewet in wet pressing of paper. Tappi J 17:479–487

Moffatt HK, Guest H, Huppert HE (2021) Spreading or contraction of viscous drops between plates: single, multiple or annular drops. J Fluid Mech. https://doi.org/10.1017/jfm.2021.668

Moonen PF, Yakimets I, Huskens J (2012) Fabrication of transistors on flexible substrates: from mass-printing to high-resolution alternative lithography strategies. Adv Mater 24:5526–5541. https://doi.org/10.1002/adma.201202949

Nagel M, Gallaire F (2013) A new prediction of wavelength selection in radial viscous fingering involving normal and tangential stresses. Phys Fluids 25:124107. https://doi.org/10.1063/1.4849495

Nase J, Derks D, Lindner A (2011) Dynamic evolution of fingering patterns in a lifted Hele-Shaw cell. Phys Fluids 23:123101. https://doi.org/10.1063/1.3659140

Park S, Jeon Y, Cho M et al (2012) The FEM based liquid transfer model in gravure offset printing using phase field method. Microsyst Technol. https://doi.org/10.1007/s00542-012-1652-4

Paterson L (1981) Radial fingering in a Hele Shaw cell. J Fluid Mech 113:513–529. https://doi.org/10.1017/S0022112081003613

Poivet S, Nallet F, Gay C, Fabre P (2003) Cavitation-induced force transition in confined viscous liquids under traction. EPL 62:244. https://doi.org/10.1209/epl/i2003-00352-3

Poivet S, Nallet F, Gay C et al (2004) Force response of a viscous liquid in a probe-tack geometry: fingering versus cavitation. Eur Phys J E 15:97–116. https://doi.org/10.1140/epje/i2004-10040-2

Reis PM, Jung S, Aristoff JM, Stocker R (2010) How cats lap: water uptake by Felis catus. Science 330:1231–1234. https://doi.org/10.1126/science.1195421

Rostami A (2021) Experimental investigations of the effect of surface roughness on high-acceleration film splitting between two substrate, Master's Thesis. University of British Columbia

Saffman PG, Taylor GI (1958) The penetration of a fluid into a porous medium or Hele-Shaw cell containing a more viscous liquid. Proc R Soc Lond Ser A Math Phys Sci 245:312–329. https://doi.org/10.1098/rspa.1958.0085

Sinha S, Kabiraj SK, Dutta T, Tarafdar S (2003) Radially interrupted viscous fingers in a lifting Hele-Shaw cell. Eur Phys J B 36:297–300. https://doi.org/10.1140/epjb/e2003-00347-4

Sinha S, Dutta T, Tarafdar S (2008) Adhesion and fingering in the lifting Hele-Shaw cell: role of the substrate. Eur Phys J E 25:267–275. https://doi.org/10.1140/epje/i2007-10289-9

Terpetschnig E, Povrozin Y, Eichorst J (2018) Long-Wavelength Polarization Standards. ISS Technical Note

Weickgenannt CM, Roisman IV, Tropea C (2012) Experimental investigation of liquid ligament fragmentation. ICLASS 8

Wenzel RN (1936) Resistance of solid surfaces to wetting by water. Ind Eng Chem 28:988–994. https://doi.org/10.1021/ie50320a024

Wu J-T, Carvalho MS, Kumar S (2019) Effects of shear and extensional rheology on liquid transfer between two flat surfaces. J Non-Newton Fluid Mech 274:104173. https://doi.org/10.1016/j.jnnfm.2019.104173

Xu C, Zhang Z, Fu J, Huang Y (2017) Study of pinch-off locations during drop-on-demand inkjet printing of viscoelastic alginate solutions. Langmuir 33:5037–5045. https://doi.org/10.1021/acs.langmuir.7b00874

Yakhnin ED, Chadov AV (1983) Investigation of the transfer of aliquid from one solid surface to another. 2. Dynamic transfer. Kolloidn Zh 45:1183–1188

Yildirim O, Basaran O (2001) Deformation and breakup of stretching bridges of Newtonian and shear-thinning liquids: comparison of one- and two-dimensional models. Chem Eng Sci 56:211–233. https://doi.org/10.1016/S0009-2509(00)00408-5

Zhang X, Padgett RS, Basaran OA (1996) Nonlinear deformation and breakup of stretching liquid bridges. J Fluid Mech 329:207–245. https://doi.org/10.1017/S0022112096008907

Funding

This study was supported by AstenJohnson Inc. and the Natural Sciences and Engineering Research Council of Canada (NSERC). This research was undertaken, in part, thanks to funding from the Canada Research Chairs program.

Author information

Authors and Affiliations

Contributions

AR developed the experimental apparatus and obtained and analyzed the experimental data. SG and BS were responsible for research supervision. All co-authors meaningfully contributed to manuscript writing and review prior to submission.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing interests that could have influenced the work reported in this paper.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rostami, A., Stoeber, B. & Green, S. Experimental investigation of substrate roughness effects on high-acceleration film splitting. Exp Fluids 63, 176 (2022). https://doi.org/10.1007/s00348-022-03526-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00348-022-03526-2