Abstract

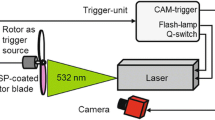

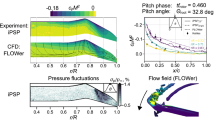

Fast-responding pressure-sensitive paint (Fast PSP) and temperature-sensitive paint (TSP) measurements were conducted on two turbocharger compressors using a single-shot lifetime-based technique. The fast PSP and TSP were applied on separate blades of one compressor, and both paints were excited by a pulsed 532 nm Nd:YAG laser. The luminescent decay signals following the laser pulse were recorded by a CCD camera in a double-exposure mode. Instantaneous pressure and temperature fields on compressor blades were obtained simultaneously, for rotation speeds up to 150,000 rpm. The variations in pressure and temperature fields with rotation speed, flow rate and runtime were clearly visualized, showing the advantage of high spatial resolution. Severe image blurring problems and significant temperature-induced errors in the PSP results were found at high rotation speeds. The first issue was addressed by incorporating a deconvolution-based deblurring algorithm to recover the clear image from the blurred image using the combination of luminescent lifetime and rotation speed. The second issue was resolved by applying a pixel-by-pixel temperature correction based on the TSP results. The current technique has shown great capabilities in flow diagnostics of turbomachinery and can serve as a powerful tool for CFD validations and design optimizations.

Similar content being viewed by others

Abbreviations

- I :

-

Intensity

- I 0 :

-

Intensity at the beginning of luminescent decay

- I 1 :

-

Intensity of gate 1

- I 2 :

-

Intensity of gate 2

- I PSP :

-

Intensity of PSP

- I PSP_ref :

-

Intensity of PSP at reference condition

- I TSP :

-

Intensity of TSP

- I TSP_ref :

-

Intensity of TSP at reference condition

- I ref :

-

Intensity at reference condition

- k :

-

Ratio of temperature sensitivity between PSP and TSP

- n :

-

Rotation speed

- P :

-

Pressure

- P ref :

-

Pressure at reference condition

- Q :

-

Flow rate

- Q ref :

-

Flow rate at reference condition

- T :

-

Temperature

- T ref :

-

Temperature at reference condition

- t :

-

Time

- V tip :

-

Compressor tip speed

- x :

-

Coordinate in streamwise direction

- ΔP :

-

Pressure difference on separate blades measured by PSP

- ΔT :

-

Temperature change

- Δt :

-

Time duration of image blur

- Δθ :

-

Angular displacement during image blur

- θ :

-

Circumferential angle

- θ 0 :

-

Circumferential angle range occupied by one blade

- τ :

-

Luminescent lifetime

- τ ref :

-

Luminescent lifetime at reference condition

- ω :

-

Angular velocity

References

Ainsworth RW, Miller RJ, Moss RW, Thorpe SJ (2000) Unsteady pressure measurement. Meas Sci Technol 11:1055–1076. doi:10.1088/0957-0233/11/7/319

Bencic TJ (1998) Rotating pressure and temperature measurements on scale-model fans using luminescent paints. In: 34th AIAA/ASME/SAE/ASEE joint propulsion conference and exhibit, AIAA 1998-3452

Burns S, Sullivan JP (1995) The use of pressure sensitive paints on rotating machinery. In: 16th international congress on instrumentation in aerospace simulation facilities

Disotell KJ, Peng D, Juliano TJ, Gregory JW, Crafton JW, Komerath NM (2014) Single-shot temperature- and pressure-sensitive paint measurements on an unsteady helicopter blade. Exp Fluids 55:1671. doi:10.1007/s00348-014-1671-2

Engler RH, Klein C, Trinks O (2000) Pressure sensitive paint systems for pressure distribution measurements in wind tunnels and turbomachines. Meas Sci Technol 11:1077–1085. doi:10.1088/0957-0233/11/7/320

Goss L, Jones G, Crafton J, Fonov S (2004) Temperature compensation in time-resolved pressure measurments. In: International symposium of flow visualization

Goss L, Jones G, Crafton J, Fonov S (2005) Temperature compensation for temporal (lifetime) pressure sensitive paint measurements. In: 43rd AIAA aerospace sciences meeting and exhibit, AIAA-2005-1027

Gregory JW (2004) Porous pressure-sensitive paint for measurement of unsteady pressures in turbomachinery. In: 42nd AIAA aerospace sciences meeting and exhibit, AIAA 2004-0294

Gregory JW, Asai K, Kameda M, Liu T, Sullivan JP (2008) A review of pressure-sensitive paint for high-speed and unsteady aerodynamics. Proc Inst Mech Eng G J Aerosp 222:249–290. doi:10.1243/09544100JAERO243

Gregory JW, Kumar P, Peng D, Fonov S, Crafton J, Liu T (2009) Integrated optical measurement techniques for investigations of fluid-structure interactions. In: 39th AIAA fluid dynamics conference, AIAA 2009-4044

Gregory JW, Sakaue H, Liu T, Sullivan JP (2014a) Fast pressure-sensitive paint for flow and acoustic diagnostics. Ann Rev Fluid Mech 56:303–330. doi:10.1146/annurev-fluid-010313-141304

Gregory JW, Disotell KJ, Peng D, Juliano TJ, Crafton J, Komerath NM (2014b) Inverse methods for deblurring pressure-sensitive paint images of rotating surfaces. AIAA J 52(9):2045–2061

Guizar-Sicairos M, Thurman ST, Fienup JR (2008) Efficient subpixel image registration algorithms. Opt Lett 33:156–158

Juliano TJ, Kumar P, Peng D, Gregory JW, Crafton J, Fonov S (2011) Single-shot, lifetime-based pressure-sensitive paint for rotating blades. Meas Sci Tech 22:085403. doi:10.1088/0957-0233/22/8/085403

Juliano TJ, Disotell KJ, Gregory JW, Crafton JW, Fonov SD (2012) Motion-deblurred, fast-response pressure-sensitive paint on a rotor in forward flight. Meas Sci Tech 23:045303. doi:10.1088/0957-0233/23/4/045303

Kameya T, Matsuda Y, Yamaguchi H, Egami Y, Niimi T (2011) Pressure-sensitive paint measurement on co-rotating disks in a hard disk drive. Opt Laser Eng. doi:10.1016/j.optlaseng.2011.06.022

Klein C, Henne U, Sachs W, Hock S, Falk N, Beifuss U, Ondrus V, Schaber S (2013) Pressure measurement on rotating propeller blades by means of the pressure-sensitive paint lifetime method. In: 51st AIAA aerospace sciences meeting, AIAA 2013-0483

Liu T, Sullivan JP (2005) Pressure and temperature sensitive paints. Springer, New York

Liu T, Torgerson S, Sullivan JP, Johnston R, Fleet S (1997) Rotor blade pressure measurement in a high speed axial compressor using pressure and temperature sensitive paints. In: 35th AIAA aerospace sciences meeting & exhibit, AIAA 1997-0162

Pandey A, Gregory JW (2016) Frequency-response characteristics of polymer/ceramic pressure-sensitive paint. AIAA J 54:174–185. doi:10.2514/1.J054166

Pastuhoff M, Tillmark N, Alfredsson PH (2016) Measuring surface pressure on rotating compressor blades using pressure sensitive paint. Sensors 16:344. doi:10.3390/s16030344

Peng D, Jensen CD, Juliano TJ, Gregory JW, Crafton J, Palluconi S, Liu T (2013) Temperature-compensated fast pressure-sensitive paint. AIAA J 51:2420–2431. doi:10.2514/1.J052318

Peng D, Jiao L, Liu Y (2016) Development of a grid PSP/TSP system for unsteady measurements on rotating surfaces. In: 32nd AIAA aerodynamic measurement technology and ground testing conference, AIAA 2016-3405

Ribarić S, Milani M, and Kalafatić Z (2000) Restoration of images blurred by circular motion. In: Proceedings of the 1st international workshop on image and signal processing and analysis

Sieverding CH, Arts T, Denos R, Brouckaert JF (2000) Measurement techniques for unsteady flows in turbomachines. Exp Fluids 28:285–321. doi:10.1007/s003480050390

Watkins AN, Leighty BD, Lipford WE, Wong OD, Oglesby DM, Ingram JL (2007) Development of a pressure sensitive paint system for measuring global surface pressures on rotorcraft blades. In: 22nd international congress on instrumentation in aerospace simulation facilities. doi:10.1109/ICIASF.2007.4380888

Watkins AN, Leighty BD, Lipford WE, Goodman KZ, Crafton J, Gregory JW (2016) Measuring surface pressures on rotor blades using pressure-sensitive paint. AIAA J 54:206–215. doi:10.2514/1.J054191

Wong OD, Watkins AN, Ingram JL (2005) Pressure-sensitive paint measurements on 15% scale rotor blades in Hover. In: 35th AIAA fluid dynamics conference and exhibit, AIAA 2005-5008

Wong OD, Noonan KW, Watkins AN, Jenkins LN, Yao C (2010) Non-intrusive measurements of a four-bladed rotor in hover—a first look. In: American helicopter society aeromechanics specialists’ conference

Yorita D, Asai K, Klein C, Henne U, Shaber S (2012) Transition detection on rotating propeller blades by means of temperature-sensitive paint. In: 50th AIAA aerospace sciences meeting, AIAA 2012-1187

Acknowledgements

This work was supported by funding from the IHI Corporation, the National Natural Science Foundation of China (NSFC No. 11502144) and the Gas Turbine Research Institute of Shanghai Jiao Tong University. The authors greatly appreciate the assistance from Mr. Chunhua Cao, Mr. Xinhua Cao and other staff members of WIT during the turbocharger tests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peng, D., Jiao, L., Yu, Y. et al. Single-shot lifetime-based PSP and TSP measurements on turbocharger compressor blades. Exp Fluids 58, 127 (2017). https://doi.org/10.1007/s00348-017-2416-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00348-017-2416-9