Abstract

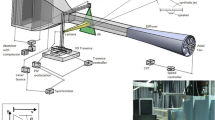

The present work is an experimental investigation inside a rectangular duct for flow behind a trapezoidal type of rib with chamfering angle α (toward the direction of flow) at different Reynolds numbers. Chamfering angle α has been varied in between 0° and 20° with an increment of 5° and subsequently detailed fluid flow and heat transfer experiments have been performed at four different Reynolds numbers, that is, 9,400, 27,120, 44,600, and 61,480 (based on hydraulic diameter of the duct). In order to investigate the detailed fluid flow and heat transfer characteristics together, a distinct experimental setup has been designed while using 2-D particle image velocimetry and liquid crystal thermography, respectively. Flow investigations have been restricted within the streamwise location of x/e ≤ 11, while the region of interest for heat transfer measurement goes up to x/e ≤ 50. The emphasis is toward assessing and analyzing the potential impact of varying chamfering angle over the flow structures, and its subsequent effect on far downstream heat transfer enhancement, as well as its role in obviating the hot spots in the adjacent vicinity behind the chamfered rib turbulators. Transient heat transfer investigation has been performed for evaluating the surface heat transfer enhancement. Results are documented in terms of stream traces, mean and rms velocity fields, streamwise Reynolds stresses and vorticity distribution, and surface and spanwise averaged augmentation Nusselt numbers. The reattachment length has been identified for all of the configurations, and the turbulent characteristics have been discussed in reference to the reattaching shearing layer and its potential impact on the size of the recirculation bubble for different configurations and conditions. The result showed the successful impact of changing the trapezoidal angle α by manipulating the small-scale vortices at the leeward corner of the rib which helps in obviating the hot spots. Furthermore, the presence of large scale unsteady vortical structure within the shear layer has been confirmed, and it has been subsequently associated with heat transfer enhancement in the far downstream region.

Similar content being viewed by others

Abbreviations

- D h :

-

Hydraulic diameter (m)

- h :

-

Convective heat transfer coefficient (W/m2K)

- k :

-

Thermal conductivity of perspex substrate (W/mK)

- Nu :

-

Local Nusselt number of the surface with a rib

- Re :

-

Reynolds number based on duct hydraulic diameter

- Re θ :

-

Reynolds number based on boundary layer momentum thickness

- U r :

-

Centerline velocity (m/s)

- u :

-

Time-averaged streamwise velocity component (m/s)

- v :

-

Time-averaged cross-stream velocity component (m/s)

- ()av :

-

Area averaged quantity

- ()rms :

-

Root mean square quantity

- −u′v′:

-

Time-averaged Reynolds shear stress

- α :

-

Trapezoidal angle of the rib

- ω z :

-

Time-averaged vorticity along Z-direction (s−1)

References

Ahn SW (2001) The effect of roughness type on friction factors and heat transfer in roughened rectangular duct. Int Commun Heat Mass Transf 28:933–942

Ali MS, Tariq A, Gandhi BK (2012) Detailed investigation on rib turbulated flow inside a rectangular duct. In: Proceedings of the ASME international mechanical engineering congress and exposition, 7-8-6 FIPFM—VI: measurement techniques-IMECE2012-87636 II, Texas, USA, November pp 9–15

Chan TL, Ashforth-Frost S, Jambunathan K (2001) Calibrating for viewing angle effect during heat transfer measurements on a curved surface. Int J Heat Mass Transf 44:2209–2223

Chandra PR, Fontenot ML, Han JC (1998) Effect of rib profiles on turbulent channel flow heat transfer. J Thermophys Heat Transf 12:116–118

Chyu MK, Ding H, Downs JP, Soechting FO (1998) Determination of local heat transfer coefficient based on bulk mean temperature using a transient liquid crystals technique. Exp Therm Fluid Sci 18:142–149

Ekkad SV, Han JC (2000) A transient liquid crystal thermography technique for gas turbine heat transfer measurements. Meas Sci Technol 11:957–968

Fröhlich J, Mellen CP, Rodi W, Temmerman L, Leschziner MA (2005) Highly resolved large-eddy simulation of separated flow in a channel with streamwise periodic constrictions. J Fluid Mech 526:19–66

Gao X (2002) Heat transfer and fluid flow investigation in ribbed ducts and impinging jets using liquid crystal thermography and PIV. Ph. D. Thesis, Division of Heat Transfer, Lund Institute of Technology, Lund

Heidmannn JD (1994) Determination of a transient heat transfer property of acrylic using thermochromic liquid crystals. NASA Tech. Report, NSN 7540-01-280-5500

Jeschke P, Biertumpfel R, Beer H (2000) Liquid-crystal thermography for heat-transfer measurements in the presence of longitudinal vortices in a natural convection flow. Meas Sci Technol 11:447–453

Kamali R, Binesh AR (2008) The importance of rib shape effects on the local heat transfer and flow friction characteristics of square ducts with ribbed internal surfaces. Int Commun Heat Mass Transf 35:1032–1040

Karwa R, Maheshwari BK, Karwa N (2008) Flow visualization and local mass transfer studies for turbulent flow in a wind tunnel with chamfered ribs. J Vis 11:205–212

Keane RD, Adrian RJ (1990) Optimization of particle image velocimeters. Part I: double-pulsed system. Meas Sci Technol 1:1202–1215

Keane RD, Adrian RJ (1991) Optimization of particle image velocimeters, Part II: multiple-pulsed systems. Meas Sci Technol 2:963–974

Kline SJ, McClintock FA (1953) Describing uncertainties in single sample experiments. Mech Eng 75:3–8

Liou TM, Hwang JJ (1993) Effect of ridge shapes on turbulent heat transfer and friction in rectangular channel. Int J Heat Mass Transf 36:931–940

Liou TM, Chang Y, Hwang DW (1990) Experimental and computational study of turbulent flows in a channel with two pairs of turbulence promoters in tandem. J Fluid Eng 112:302–310

Panigrahi PK, Acharya S (2004) Multi-modal forcing of the turbulent separated shear flow past a rib. J Fluid Eng 126:22–31

Panigrahi PK, Tariq A (2003) Liquid crystal heat transfer measurements in a rectangular channel with solid and slit rib. J Vis 6:407–416

Panigrahi PK, Schroder A, Kompenhans J (2006) PIV investigation of flow behind surface mounted permeable ribs. Exp Fluid 40:277–300

Panigrahi PK, Schroeder A, Kompenhans J (2008) Turbulent structures and budgets behind permeable ribs. Exp Therm Fluid Sci 32:1011–1033

Schultz DL, Jones TV (1973) Heat transfer measurements in short duration hypersonic facilities. NATO Advisory Group Aeronautical RD AGARDOGRAPH

Son SY, Kihm KD, Han JC (2002) PIV flow measurements for heat transfer characterization in two-pass square channels with smooth and 90° ribbed walls. Int J Heat Mass Transf 45:4809–4822

Tariq A, Singh K, Panigrahi PK (2003) Flow and heat transfer in rectangular duct with single rib and two ribs mounted on the bottom surface. J Enhanc Heat Transf 10:171–198

Tariq A, Panigrahi PK, Muralidhar K (2004) Flow and heat transfer in the wake of a surface-mounted rib with a slit. Exp Fluid 37:701–719

Visscher J, Andersson HI, Barri M, Didelle H, Viboud S, Sous D (2011) A new set-up for PIV measurements in rotating turbulent duct flows. Flow Meas Instrum 22:71–80

Wang L, Sunden B (2007) Experimental investigation of local heat transfer in a square duct with various-shaped ribs. Heat Mass Transf 43:759–766

Wang L, Hejcik J, Sunden B (2007) PIV measurement of separated flow in a square channel with streamwise periodic ribs on one wall. J Fluid Eng 129:834–841

Wang L, Salewski M, Sunden B (2010) Turbulent flow in a ribbed channel: flow structures in the vicinity of a rib. Exp Therm Fluid Sci 34:165–176

Wiberg R, Lior N (2004) Errors in thermochromic liquid crystal thermometry. Rev Sci Instrum 75:2985–2994

Acknowledgments

The author acknowledges the financial support of the Ministry of Human Resource and Development (MHRD), India for initiating this research activity in Mechanical & Industrial Engineering Department at Indian Institute of Technology Roorkee, India. Further authors wish to extend sincere thanks and acknowledge the support of Department of Science and Technology (DST), India for providing the financial assistance in order to improve the laboratories at IIT Roorkee under the FIST Grant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ali, M.S., Tariq, A. & Gandhi, B.K. Flow and heat transfer investigation behind trapezoidal rib using PIV and LCT measurements. Exp Fluids 54, 1520 (2013). https://doi.org/10.1007/s00348-013-1520-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00348-013-1520-8