Abstract

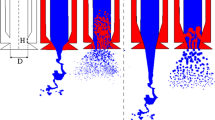

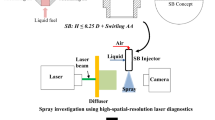

This paper presents the results of an experimental study of a twin-fluid internally mixed swirl atomizer. In this type of injectors, atomization is attained by injecting a small amount of air (i.e. of the order of less than 16% of the mass flow rate of liquid) into a liquid stream within the injector and the two-phase air liquid mixture is passed through a swirling passage to impart a swirling motion to the flow. Since most of the energy for atomization is supplied to the liquid by the atomizing air, a significantly small pressure drop can produce very fine spray with a small amount of atomizing air. At low values of air–liquid mass ratio (ALR), the appreciable tangential component of velocity with respect to the axial velocity provides a hollow cone spray structure, which turns into a solid cone spray with the increase in axial momentum, through either an increase in ALR or the liquid supply pressure. The results presented in this paper suggest that the investigated injector could be used to control the flow rate and spray characteristics (e.g. spray cone angle, spray solidity, breaking distance, and the droplet diameter) independent of each other by simultaneously varying the supply pressure of the liquid and the atomizing air flow rate. The controlled atomization studied in this paper for a twin-fluid internally mixed swirl atomizer makes it attractive to be used for various commercial applications as the atomizer is capable of providing various spray characteristics depending upon the application requirement.

Similar content being viewed by others

Abbreviations

- ALR:

-

ratio of mass flow rates of the air to that of the liquid

- D b :

-

spray break-up distance/breaking distance

- D orifice :

-

orifice diameter

- SMD:

-

Sauter’s Mean Diameter

References

Beyvel L, Orzechowski Z (1993) Liquid Atomization. Taylor and Francis, Philadelphia, PA

Biswas MN (1982) Atomization in two-phase critical flows. In: Proceedings of the 2nd International Conference on Liquid Atomization and Sprays, pp 145–151

Chigier NA (1993) Spray science and technology, fluid mechanics and heat transfer in sprays. ASME Fluid Eng Div Publ FED 178:1–18

Chin JS (1995) Effervescent atomization and internal mixing air-assisted atomization. Int J Turbo Jet Engines 12:119–127

Griffen E, Maraszew A (1953) The atomization of liquid fuels. Chapman and Hall Ltd., London

Karnawat J, Kushari A (2005) Spray evolution in a twin-fluid swirl atomizer. In proceedings ILASS—Asia, Seoul, Korea, 11–13 October 2005

Kushari A, Neumeier Y, Israeli O, Lubarsky E, Zinn BT (2001) Internally mixed liquid injector for active control of atomization process. AIAA J Propulsion Power 17(4):878–882

Lee JY, Kushari A, Lubrasky E, Zinn BT, Rozenberg S, Levy Y (2002) Control of combustion instabilities and emissions using an internally mixed liquid atomizer with a vaporizer. In: proceedings of AIAA 2002-0617, 40th aerospace sciences meeting and exhibit. Reno, NV

Lefevbre AH (1983) Gas turbine combustion. Hemisphere Publishing Corporation, Washington, DC

Lefevbre AH (1985) Fuel effects on gas turbine combustion—ignition, stability and combustion efficiency. ASME J Eng Gas Turbine Power 107:24–37

Lefevbre AH (1989) Atomization and spray. Hemishpere Publishing Corporation, New York

Levy Y, Lubarsky E (1996) Oscillating control spray for the suppression of the low frequency combustion instabilities. In: Proceedings of 36th Israel annual conference on aerospace sciences, Haifa, Israel

Mullinger PJ, Chigier NA (1974) The design and performance of internal mixing multijet twin fluid atomizers. J Inst Fuels 47:251–261

Ramamurthi K, Tharakan TJ (1995) Experimental study of liquid sheets formed in coaxial swirl injectors. AIAA J Propulsion Power 11(6):1103–1109

Ramamurthi K, Tharakan TJ (1998) Flow transition in swirled liquid sheets. AIAA J 36(3):420–427

Reeves CM, Lefevbre AH (1986) Fuel effects on aircraft combustor emissions. ASME paper 86-GT-212

Rink KK, Lefevbre AH (1987) Pollutant formation in heterogeneous mixtures of fuel drops and air. AIAA J Propulsion Power 3(1):5–10

Roesler TC, Lefevbre AH (1989) Studies on aerated liquid atomization. Int J Turbo Jet Engines 6(3–4):221–230

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karnawat, J., Kushari, A. Controlled atomization using a twin-fluid swirl atomizer. Exp Fluids 41, 649–663 (2006). https://doi.org/10.1007/s00348-006-0191-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00348-006-0191-0