Abstract

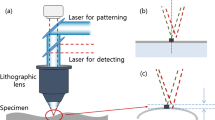

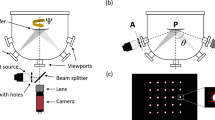

Line curvature error greatly influences the quality of the diffraction wave fronts of machine-ruling gratings. To reduce the line curvature error, we propose a correction method that uses interferometric control. This method uses diffraction wave fronts of symmetrical orders to compute the mean line curvature error of the ruled grating, taking the mean line curvature error as the system line curvature error. To minimize the line curvature error of the grating, a dual-frequency laser interferometer is used as a real-time position feedback for the grating ruling stage, along with using a piezoelectric actuator to adjust the stage positioning to compensate the line curvature error. Our experiments show that the proposed method effectively reduced the peak-to-valley value of the line curvature error, improving the quality of the grating diffraction wave front.

Similar content being viewed by others

References

G.R. Harrison, S.W. Thompson, H. Kazukonis, J.R. Connell, 750-mm ruling engine producing large gratings and echelles. J. Opt. Soc. Am. 62(6), 751–756 (1972)

F.M. Gerasimov, Use of diffraction gratings for controlling a ruling engine. Appl. Opt. 6(11), 1861–1864 (1967)

T. Jitsuno1, S. Motokoshi et al., Development of 91 cm size gratings and mirrors for LEFX laser system. J. Phys Conf. Ser. 112, 1–4 (2008)

T. Suzuki, H. Kubo et al., High-resolution multi grating spectrometer for high quality deep UV light source production. Proc. SPIE Opt. Microlithogr. XIV 4346, 1254–1261 (2001)

J. Flamand, F. Bonnemason, A. Thevenon, The blazing of holographic gratings using ion-etching. Proc. SPIE 1055, 288–294 (1989)

D. Nevejans, E. Neefs, E. van Ransbeeck et al., Compact high-resolution spaceborne echelle grating spectrometer with acousto-optical tunable filter based order sorting for the infrared domain from 2.2 to 4.3 μm. Appl. Opt. 45(21), 5191–5206 (2006)

K. Takashima, S. Nawata, Diffraction grating ruling engine with piezoelectric control. Jpn. J. Appl. Phys. 17(8), 1445–1446 (1978)

I.R. Bartlett, P.C. Wildy, Diffraction grating ruling engine with piezoelectric drive. Appl. Opt. 14(1), 1–3 (1975)

T. Kita, T. Harada, Ruling engine using a piezoelectric device for large and high-groove density gratings. Appl. Opt. 31(8), 1399–1406 (1992)

J. Strong, The Johns Hopkins University and diffraction gratings. J. Opt. Soc. Am. 50(12), 1148–1152 (1960)

G.R. Harrison, The production of diffraction gratings I. Development of the ruling art. J. Opt. Soc. Am. 39(6), 413–425 (1949)

G.R. Harrison, G.W. Stroke, Interferometric control of grating ruling with continuous carriage advance. J. Opt. Soc. Am. 45(2), 112–120 (1955)

G.R. Harrison, Techniques for Ruling Improved Large Diffraction Gratings Final Report (Massachusetts Institute of Technology, Cambridge, 1971), pp. 1–14

G.R. Harrison, The diffraction grating—an opinionated appraisal. Appl. Opt. 12(9), 2039–2048 (1973)

X. Li, B. Bayanheshig, X. Qi et al., Influence and revising method of machine-ruling grating line’s curve error, location error on plane grating’s performance. Chin. J. Lasers 40(3), 0308009 (2013). (in Chinese)

X. Li, Bayanheshig, X. Qi et al., Two-dimensional fast Fourier transform method of analyzing the influence of plane grating’s line error and surface error. Acta Opt. Sin. 32(11), 1105001 (2012). (in Chinese)

Z. Jaroszewicz, Interferometric testing of the spacing error of a plane diffraction grating. Opt. Commun. 60(6), 345–349 (1986)

G.R. Harrison, N. Sturgis et al., Interferometrically controlled ruling of ten-inch diffraction gratings. J. Opt. Soc. Am. 49(3), 205–211 (1959)

G.W. Stroke, Attainment of high-resolution gratings by ruling under interferometric control. J. Opt. Soc. Am. 51(10), 1321–1339 (1961)

Acknowledgments

The authors acknowledge supports from the Chinese Finance Ministry for the National R&D Projects for Key Scientific Instruments (Grant ZDYZ2008-1) and from Ministry of national science and technology for National Key Basic Research Program of China (Grant 2014CB049500).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, H., Li, X., Zhu, J. et al. Reducing the line curvature error of mechanically ruled gratings by interferometric control. Appl. Phys. B 117, 279–286 (2014). https://doi.org/10.1007/s00340-014-5832-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-014-5832-z