Abstract

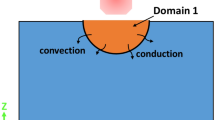

This study presents a methodology for estimating the melt depth during laser processing of solid materials. The determination of the melt depth is treated as an inverse heat conduction problem, which includes the solid and liquid phases. The conjugate gradient method is applied to treat the inverse problem using the available temperature measurements. Without the inverse methodology the melt depth is very difficult to obtain with precision. The proposed method can also be applied during microthermal machining to determine the location of the solid–liquid interface and the temperature distributions of the two phases by using scanning thermal microscopy.

Similar content being viewed by others

References

J. McGeough, Micromachining of Engineering Materials (Marcel-Dekker, New York 2002)

W.M. Sten, J. Opt. A: Pure Appl. Opt. 5, 3 (2002)

R. Griffith, B. Nassersharif, Numer. Heat Transfer B 18, 169 (1990)

H.S. Lee, H. Merte Jr., Int. J. Heat Mass Transfer 39, 2427 (1996)

D.M. Christopher, Numer. Heat Transfer B 39, 189 (2001)

J. Xie, A. Kar, J. Appl. Phys. 81, 3015 (1997)

Z.H. Shen, S.Y. Zhang, J. Lu, X.W. Ni, Opt. Laser Technol. 33, 533 (2001)

J.V. Beck, B. Blackwell, C.R. St. Clair Jr., Inverse Heat Conduction: Ill-Posed Problems (Wiley-Interscience, New York 1985)

O.M. Alifanov, Inverse Heat Transfer Problem (Springer, Berlin, Heidelberg, New York 1994)

B. Sawaf, M.N. $Ozisik, Y. Jarny, Int. J. Heat Mass Transfer 38, 3005 (1995)

A.J. Silva Neto, M.N. $Ozisik, J. Appl. Phys. 71, 5357 (1992)

W.J. Chang, C.I. Weng, Int. J. Heat Mass Transfer 42, 2661 (1999)

W.J. Chang, T.H. Fang, C.I. Weng, Nanotechnology 15, 427 (2004)

Y.C. Yang, S.S. Chu, W.J. Chang, J. Appl. Phys. 95, 159 (2004)

H.S. Carslaw, J.C. Jaeger, Conduction of Heat in Solids, 2nd edn. (Oxford University Press, London 1959)

A. Hammiche, L. Bozec, M. Conror et al., J. Vac. Sci. Technol. B 18, 1322 (2000)

H.M. Pollock, A. Hammiche, J. Phys. D: Appl. Phys. 34, R23 (2001)

T.H. Fang, W.J. Chang, Appl. Surf. Sci., in press.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, WJ., Fang, TH. Modelling of the solid–liquid interface during laser processing using an inverse methodology. Appl. Phys. B 80, 373–376 (2005). https://doi.org/10.1007/s00340-005-1740-6

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/s00340-005-1740-6