Abstract

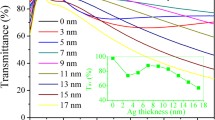

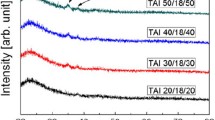

The transparent flexible SnO2:Mo/Ag/SnO2:Mo (MTO/Ag/MTO) triple-layer film was prepared based on co-sputtering at room temperature for the first time. The optimization of the MTO layer thickness on the optical and electrical properties of the triple-layer films was investigated and the bending stability was verified by bending test. It was found that the visible light transmittance of the triple-layer film increases first and then decreases with the increase of MTO layer thickness, which indicates that the MTO layer thickness plays an important role in optimizing the visible light transmittance of the triple-layer film. Also, as the thickness of the MTO layer increases, the triple-layer film carrier concentration decreases and the sheet resistance increases. Therefore, the triple-layer film with excellent properties was obtained via the optimization of the MTO layer thickness to 40 nm, which has a maximum figure of merit of 2.0 × 10–2 Ω−1, a high visible light transparency of 82% and a low sheet resistance of 6.9 Ω/sq. Meanwhile, the prepared triple-layer film also has excellent mechanical flexibility (curvature radius R ≥ 4 mm, and the number of bending times is 10,000).

Similar content being viewed by others

Data availability

Data underlying the results presented in this paper are not publicly available at this time but maybe obtained from the authors upon reasonable request.

References

A. Baltakesmez, B. Güzeldir, Appl. Phys. A 129, 2 (2023)

W. Yang, H. Yang, J. Su, X. Zhang, Vaccum 205, 111419 (2022)

A. Kumar, S.Y. Lee, Microelectron. Eng. 261, 111794 (2022)

W. Pan, X. Zhou, Y. Li, W. Dong, L. Lu, S. Zhang, Mater. Sci. Semicond. Process. 151, 106998 (2022)

C.X. Huang, J. Li, Y.Z. Fu, J.H. Zhang, X.Y. Jiang, Z.L. Zhang, Q.H. Yang, J. Alloys Compd. 681, 81–87 (2016)

A. Panca, J. Panidi, H. Faber, S. Stathopoulos, T.D. Anthopoulos, T. Prodromakis, Adv. Funct. Mater. 33, 20 (2023)

X. Yin, D. Lin, W. Zhong, Y. Chen, G. Li, Y. Li, R. Chen, Solid State Electron. 208, 108726 (2023)

M.E. Rivas-Aguilar, N. Hernandez-Como, G. Gutierrez-Heredia, A. Sánchez-Martínez, M.M. Ramirez, I. Mejia, M.A. Quevedo-López, Curr. Appl. Phys. 18, 7 (2018)

E.R. Ollotu, J.S. Nyarige, N.R. Mlyuka, M.E. Samiji, M. Diale, J. Mater. Sci. Mater. Electron. 31, 19 (2020)

S. Song, T. Yang, J. Liu, Y. Xin, Y. Li, S. Han, Appl. Surf. Sci. 257, 16 (2011)

A.H. Ali, Z. Hassan, A. Shuhaimi, Appl. Surf. Sci. 443, 544–547 (2018)

H. Khachatryan, D.J. Kim, M. Kim, H.K. Kim, Mater. Sci. Semicond. Process. 88, 51–56 (2018)

J.H. Park, C. Buurma, S. Sivananthan, R. Kodama, W. Gao, T.A. Gessert, Appl. Surf. Sci. 307, 388–392 (2014)

S. Seong, Y.C. Jung, T. Lee, I.S. Park, J. Ahn, Mater. Sci. Semicond. Process. 79, 14–19 (2018)

N. Meshram, C. Loka, K.R. Park, K.S. Lee, Mater. Lett. 145, 120–124 (2015)

S.J. Oh, S. Lee, K.C. Choi, J.H. Kwon, T.S. Kim, J. Mater. Chem. C 11, 22 (2023)

K. Sivaramakrishnan, N.D. Theodore, J.F. Moulder, T.L. Alford, J. Appl. Phys. 106, 6 (2009)

H. Salmaniannezhad, H. Salmaniannezhad, R. Zarei-Moghadam, M. Khani, M. Ardani, B. Shokri, Progress Phys. Appl. Mater. 3, 2 (2023)

H. Wang, C. Tang, Q. Shi, M. Wei, Y. Su, S. Lin, M. Dai, Ceram. Int. 47, 6 (2021)

H. Ghasemi, M.H. Mozaffari, R. Moradian, N. Ghobadi, Mater. Sci. Semicond. Process. 149, 106853 (2022)

S.H. Park, S.J. Lee, J.H. Lee, J. Kal, J. Hahn, H.K. Kim, Org. Electron. 30, 112–121 (2016)

M. Rabizadeh, M.H. Ehsani, M.M. Shahidi, Sci. Rep. 12, 1 (2022)

S.Y. Park, S.Y. Lee, Carbon Lett. 33, 4 (2023)

M. Rabizadeh, M.H. Ehsani, Ceram. Int. 48, 11 (2022)

Y.C. Kim, S.J. Lee, I.K. Oh, S. Seo, H. Kim, J.M. Myoung, J. Alloys Compd. 688, 1108–1114 (2016)

M. Wu, H. Zheng, X. Li, S. Yu, Ceram. Int. 46, 4 (2020)

L. Song, C. Wu, S. Yu, X. Wang, Mater. Lett. 312, 131683 (2022)

S. Yu, W. Zhang, L. Li, D. Xu, H. Dong, Y. Jin, Thin Solid Films 552, 218–224 (2014)

M. Batzill, U. Diebold, Prog. Surf. Sci. 79, 2 (2005)

D.R. Sahu, J.L. Huang, Thin Solid Films 516, 2 (2007)

E.C. Nwanna, P.E. Imoisili, T.C. Jen, J. Mater. Res. Technol. 17, 102123 (2022)

T. Ma, M. Nikiel, A.G. Thomas, M. Missous, D.J. Lewis, J. Mater. Sci. 56, 28 (2021)

J. Szczyrbowski, A. Dietrich, K. Hartig, Sol Energy Mater. 16, 1 (1987)

D.O. Scanlon, G.W. Watson, D.J. Payne, G.R. Atkinson, R.G. Egdell, D.S.L. Law, J. Phys. Chem. C 114, 10 (2010)

P. Grosse, R. Hertling, T. Müggenburg, J. Non-Cryst. Solids 218 (1997).

R. Pandey, B. Angadi, S.K. Kim, J.W. Choi, D.K. Hwang, W.K. Choi, Opt. Mater. Express 4, 10 (2014)

Z.S. Yuan, C.C. Wu, W.C. Tzou, C.F. Yang, Y.H. Chen, Vacuum 165, 305–310 (2019)

G. Haacke, New figure of merit for transparent conductors. J. Appl. Phys. 47, 9 (1976)

S.W. Cho, J.A. Jeong, J.H. Bae, J.M. Moon, K.H. Choi, S.W. Jeong, N.J. Park, J.J. Kim, S.H. Lee, J.W. Kang, M.S. Yi, H.K. Kim, Thin Solid Films 516, 21 (2008)

T.H. Kim, B.H. Choi, J.S. Park, S.M. Lee, Y.S. Lee, L.S. Park, Mol. Cryst. Liq. Cryst. 520, 1 (2010)

V. Sharma, P. Kumar, A. Kumar, Surbhi, K. Asokan, K. Sachdev, Sol Energy Mat. Sol C 169, 122–131 (2017)

Y. Zhang, L. Wang, Z. Geng, D. Zhang, D. Wang, J. Liu, Q. Wang, Mater. Sci. Semicond. Process. 165, 107643 (2023)

Y. Sugimoto, K. Igarashi, S. Shirasaki, A. Kikuchi, Jpn. J. Appl. Phys. 55, 4S (2016)

Acknowledgements

This work was supported by National Natural Science Foundation of China (No.62064001), by GuiZhou Provincial Basic Research Program (Natural Science) (No. ZK[2021]238), by Science and Technology Personnel Planning Project of GuiZhou Province (YQK[2023]018), and by Science and Technology Planning Foundation of GuiYang City (No. [2021]43-2).

Author information

Authors and Affiliations

Contributions

Min Su: Investigation, Writing-Original Draft. Suheng Shi: Investigation. Jiarong Chen: Investigation. Dasen Ren: Methodology. Lan Yue: Conceptualization, Resources, Writing-Review & Editing, Funding acquisition, Project administration. Fanxin Meng: Conceptualization, Funding acquisition, Methodology.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Su, M., Shi, S., Chen, J. et al. Preparation and optimization of MTO/Ag/MTO transparent flexible film based on co-sputtering at room temperature. Appl. Phys. A 130, 406 (2024). https://doi.org/10.1007/s00339-024-07557-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-024-07557-w