Abstract

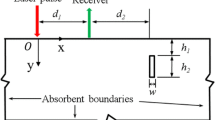

In this paper, the depth and length of lateral subsurface cracks were gauged using laser-generated Rayleigh waves in the frequency domain. First, the frequency domain characteristics of reflected and transmitted Rayleigh waves after a laser-generated Rayleigh wave interacts with lateral subsurface cracks are investigated based on the finite element method (FEM). The simulation results reveal that there is a certain relationship between the center frequency of reflected and transmitted Rayleigh waves and crack size. The center frequency of the reflected Rayleigh wave decreases with increasing crack length but is independent of depth. When the crack length remains unchanged, the center frequency of the transmitted Rayleigh wave increases with increasing crack depth. Then, the quantitative relationships between the ratio of the crack length to the incident Rayleigh wavelength and the ratio of the reflected Rayleigh wave frequency to the incident Rayleigh wave frequency, the ratio of the crack depth to the incident Rayleigh wavelength and the ratio of the transmitted Rayleigh wave frequency to the incident Rayleigh wave frequency were obtained via multiple function fitting, and a method for the quantitative detection of the lateral subsurface crack depth and length was proposed. Finally, experimental and simulated data were used to validate the proposed relationships, and the results showed that the relative error of the measured crack length did not exceed 7.19% and that the relative error of the measured crack depth did not exceed 14.82%. The results show that the method has good application prospects for the quantitative measurement of lateral subsurface crack depth and length.

Similar content being viewed by others

Data availability

All data that support the findings of this study are included within the article (and any supplementary files).

References

O.G. Diaz, G.G. Luna, Z.R. Liao, D. Axinte, The new challenges of machining ceramic matrix composites (CMCs): review of surface integrity. Int. J. Mach. Tools Manuf 139, 24–36 (2019). https://doi.org/10.1016/j.ijmachtools.2019.01.003

B. Zhang, J.F. Yin, The ‘skin effect’ of subsurface damage distribution in materials subjected to high-speed machining. Int. J. Extreme Manuf. 1(1), 012007 (2019). https://doi.org/10.1088/2631-7990/ab103b

J.F. Yin, Q. Bai, B. Zhang, Subsurface damage detection on ground silicon wafers using polarized laser scattering. J. Manuf. Sci. Eng. 141(10), 101012 (2019). https://doi.org/10.1115/1.4044417

Y. Yan, Y.H. Wang, P. Zhou, N. Huang, D.M. Guo, Near-field microscopy inspection of nano scratch defects on the monocrystalline silicon surface. Precis. Eng.-J. Int. Soc. Precis. Eng. Nanotechnol. 56, 506–512 (2019). https://doi.org/10.1016/j.precisioneng.2019.02.008

M.M. Barysheva, N.I. Chkhalo, M.N. Drozdov, M.S. Mikhailenko, A.E. Pestov, N.N. Salashchenko, Y.A. Vainer, P.A. Yunin, M.V. Zorina, X-ray scattering by the fused silica surface etched by low-energy Ar ions. J. X-Ray Sci. Technol. 27(5), 857–870 (2019). https://doi.org/10.3233/XST-190495

A.K. Kromine, P.A. Fomitchov, S. Krishnaswamy, J.D. Achenbach, Detection of subsurface defects using laser based technique. AIP Conf. Proc. 557, 1612–1617 (2001). https://doi.org/10.1063/1.1373946

T. Hayashi, N. Mori, T. Ueno, Non-contact imaging of subsurface defects using a scanning laser source. Ultrasonics 119, 106560 (2022). https://doi.org/10.1016/j.ultras.2021.106560

G.L. Lv, Z.J. Yao, D. Chen, Y.H. Li, H.Q. Cao, A.M. Yin, Y.J. Liu, S.F. Guo, Fast and high-resolution laser-ultrasonic imaging for visualizing subsurface defects in additive manufacturing components. Mater. Des. 225, 111454 (2023). https://doi.org/10.1016/j.matdes.2022.111454

P. Song, J.Y. Liu, Z.J. Li, S.Y. Wu, X.G. Sun, H.H. Yue, M. Pawlak, All-optical laser ultrasonic technique for imaging of subsurface defects in carbon fiber reinforced polymer (CFRP) using an optical microphone. J. Appl. Phys. 131(16), 165106 (2022). https://doi.org/10.1063/5.0087304

V.V. Narumanchi, F. Pourahmadian, J. Lum, A. Townsend, J.W. Tringe, D.M. Stobbe, T.W. Murray, Laser ultrasonic imaging of subsurface defects with the linear sampling method. Opt. Express 31(5), 9098–9111 (2023). https://doi.org/10.1364/OE.485084

K. Nakahata, K. Karakawa, K. Ogi, K. Mizukami, K. Ohira, M. Maruyama, S. Wada, T. Namita, T. Shiina, Three-dimensional SAFT imaging for anisotropic materials using photoacoustic microscopy. Ultrasonics 98, 82–87 (2019). https://doi.org/10.1016/j.ultras.2019.05.006

D. Levesque, A. Blouin, C. Neron, J.-P. Monchalin, Performance of laser-ultrasonic F-SAFT imaging. Ultrasonics 40(10), 1057–1063 (2002). https://doi.org/10.1016/S0041-624X(02)00256-1

J. Lin, C.Y. Wang, W. Wang, J. Chen, A.Y. Sun, B.F. Ju, Quantitative evaluation of subsurface cracks with laser-generated Rayleigh wave based on back propagation neural network. Appl. Phys. A-Mater. Sci. Process. 128(7), 581 (2022). https://doi.org/10.1007/s00339-022-05699-3

K.X. Zhang, G.L. Lv, S.F. Guo, D. Chen, Y.J. Liu, W. Feng, Evaluation of subsurface defects in metallic structures using laser ultrasonic technique and genetic algorithm-back propagation neural network. NDT E Int. 116, 102339 (2020). https://doi.org/10.1016/j.ndteint.2020.102339

S.F. Guo, H.W. Feng, W. Feng, G.L. Lv, D. Chen, Y.J. Liu, X.Y. Wu, Automatic quantification of subsurface defects by analyzing laser ultrasonic signals using convolutional neural networks and wavelet transform. IEEE Trans. Ultrason. Ferroelectr. Freq. ControlUltrason. Ferroelectr. Freq. Control 68(10), 3216–3225 (2021). https://doi.org/10.1109/TUFFC.2021.3087949

G.L. Lv, S.F. Guo, D. Chen, H.W. Feng, K.X. Zhang, Y.J. Liu, W. Feng, Laser ultrasonics and machine learning for automatic defect detection in metallic components. NDT E Int. 133, 102752 (2023). https://doi.org/10.1016/j.ndteint.2022.102752

Z.W. Liu, L. Bin, X.H. Liang, A.Y. Du, Quantifying the subsurface damage and residual stress in ground silicon wafer using laser ultrasonic technology: a Bayesian approach. Mech. Syst. Signal Proc. 173, 109008 (2022). https://doi.org/10.1016/j.ymssp.2022.109008

Y.H. Sohn, S. Krishnaswamy, The scanning laser source technique for detection of surface-breaking and subsurface defect. J. Korean Soc. Nondestruct. Test. 27(3), 246–254 (2007)

D. Chen, G.L. Lv, S.F. Guo, R. Zuo, Y.J. Liu, K.X. Zhang, Z.Q. Su, W. Feng, Subsurface defect detection using phase evolution of line laser-generated Rayleigh waves. Opt. Laser Technol. 131, 106410 (2020). https://doi.org/10.1016/j.optlastec.2020.106410

S. Everton, P. Dickens, C. Tuck, B. Dutton, Using laser ultrasound to detect subsurface defects in metal laser powder bed fusion components. JOM 70(3), 378–383 (2018). https://doi.org/10.1007/s11837-017-2661-7

C.Y. Wang, A.Y. Sun, X.Y. Yang, B.F. Ju, Y.D. Pan, Laser-generated Rayleigh wave for width gauging of subsurface lateral rectangular defects. J. Appl. Phys. 124(6), 065104 (2018). https://doi.org/10.1063/1.5028207

C. Chen, A.Y. Sun, B.F. Ju, C.Y. Wang, Width and depth gauging of rectangular subsurface defects based on all-optical laser-ultrasonic technology. Appl. Acoust.Acoust. 191, 108684 (2022). https://doi.org/10.1016/j.apacoust.2022.108684

C.Y. Wang, A.Y. Sun, X.Y. Yang, B.F. Ju, Y.D. Pan, Numerical simulation of the interaction of laser-generated Rayleigh waves with subsurface cracks. Appl. Phys. A-Mater. Sci. Process. 124(9), 613 (2018). https://doi.org/10.1007/s00339-018-2039-x

Y.K. An, Y. Kwon, H. Sohn, Noncontact laser ultrasonic crack detection for plates with additional structural complexities. Struct. Health Monit.. Health Monit. 12(5–6), 522–538 (2013). https://doi.org/10.1177/1475921713500515

J. Guan, Z. Shen, B. Xu, J. Lu, X. Ni, Numerical simulation of laser ultrasonics for detecting subsurface lateral defects. Lasers Mater. Process. Manuf. II. SPIE. 5629, 457–465 (2005). https://doi.org/10.1117/12.572869

W. Zeng, Y.Y. Yao, S.K. Qi, L. Liu, Finite element simulation of laser-generated surface acoustic wave for identification of subsurface defects. Optik 207, 163812 (2020). https://doi.org/10.1016/j.ijleo.2019.163812

H.T. Huan, A. Mandelis, L.X. Liu, B. Lashkari, A. Melnikov, Application of linear frequency modulated laser ultrasonic radar in reflective thickness and defect non-destructive testing. NDT E Int. 102, 84–89 (2019). https://doi.org/10.1016/j.ndteint.2018.11.006

C.Y. Wang, Y. Kong, W. Wang, Z.F. Chen, J. Chen, W.L. Zhu, B.F. Ju, Finite element analysis of laser-generated Rayleigh wave for sizing subsurface crack in frequency domain. Optik 260, 169145 (2022). https://doi.org/10.1016/j.ijleo.2022.169145

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant nos. 52205561, 52327807 and 12072097), the Open Foundation of the State Key Laboratory of Fluid Power and Mechatronic Systems (Grant no. GZKF-202312), and the Major Program of Zhejiang Provincial Natural Science Foundation of China (Grant no. LD22E050010).

Author information

Authors and Affiliations

Contributions

Buer Chen: Conceptualization, Data curation, Methodology, Writing – original draft. Chuanyong Wang: Funding acquisition, Resources, Supervision, Writing – review & editing. Wen Wang: Project administration. Yun Wang: Visualization. Keqing Lu: Formal analysis. Yuanping Ding: Investigation. Jian Chen: Validation. Yuanliu Chen: Software. Bing-Feng Ju: Project administration, Funding acquisition.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, B., Wang, C., Wang, W. et al. Quantitative detection of lateral subsurface cracks based on laser-generated Rayleigh waves in the frequency domain. Appl. Phys. A 130, 245 (2024). https://doi.org/10.1007/s00339-024-07402-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-024-07402-0