Abstract

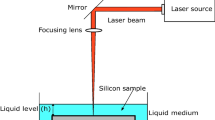

To establish the optimal processing parameters, it is imperative to gain an understanding of the interactions and ablation mechanisms between the picosecond pulsed laser and indium tin oxide (ITO) films. This research employed a picosecond pulsed laser for rear-side ablation of ITO films on polyethylene terephthalate (PET) substrates. A two-dimensional simulation temperature analysis of groove morphology was used to evaluate the elimination of ITO films through thermal evaporation. A methodical study was conducted on the effect of various laser processing parameters on the quality of the etched groove on the film’s surface. The results highlighted the importance of combining laser power and scanning speed harmoniously to achieve superior groove performance. An increase in laser power coupled with a decrease in scanning speed resulted in a widening of laser grooves, increase in molten ridge heights, and a sharper line at the edge of grooves. At a scanning speed of 3000 mm/s and a power level of 1.10 W, optimal laser processing parameters were determined. This caused the groove’s edges to display precision, the molten ridge height to be minimized, the groove width to measure 24.7 mm, and the groove termini to be completely separated. The characteristics of these discernible grooves coincide with the requirements for pragmatic groove applications.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

C.Y. Leong, S.S. Yap, G.L. Ong, T.S. Ong, S.L. Yap, Y.T. Chin, S.F. Lee, T.Y. Tou, C.H. Nee, Single pulse laser removal of indium tin oxide film on glass and polyethylene terephthalate by nanosecond and femtosecond laser. Nanotechnol. Rev.. Rev. 9(1), 1539–1549 (2020). https://doi.org/10.1515/ntrev-2020-0115

X. Li, Z. Deng, J. Li, Y. Li, L. Guo, Y. Jiang, Z. Ma, L. Wang, C. Du, Y. Wang, Q. Meng, H. Jia, W. Wang, W. Liu, H. Chen, Hybrid nano-scale Au with ITO structure for a high-performance near-infrared silicon-based photodetector with ultralow dark current. Photonics Res. 8(11), 1662 (2020). https://doi.org/10.1364/PRJ.398450

H. Kim, W. Choi, S. Ji, Y. Shin, J. Jeon, S. Ahn, S. Cho, Morphologies of femtosecond laser ablation of ITO thin films using gaussian or quasi-flat top beams for OLED repair. Appl. Phys. A (2018). https://doi.org/10.1007/s00339-018-1553-1

S. Moon, J. Yum, L. Lofgren, A. Walter, L. Sansonnens, M. Benkhaira, S. Nicolay, J. Bailat, C. Ballif, Laser-scribing patterning for the production of organometallic halide perovskite solar modules. IEEE J. Photovolt. 5(4), 1087–1092 (2015). https://doi.org/10.1109/JPHOTOV.2015.2416913

K.G. Brooks, M.K. Nazeeruddin, Laser processing methods for perovskite solar cells and modules. Adv. Energy Mater. 11(29), 2101149 (2021). https://doi.org/10.1002/aenm.202101149

S.S. Mammana, A. Greatti, F.H. Luiz, F.I. Da Costa, A.P. Mammana, G.A. Calligaris, L.P. Cardoso, C.I.Z. Mammana, D. den Engelsen, Study of wet etching thin films of indium tin oxide in oxalic acid by monitoring the resistance. Thin Solid Films 567, 20–31 (2014). https://doi.org/10.1016/j.tsf.2014.07.027

Y.C. Chung, Y.H. Chiu, H.J. Liu, Y.F. Chang, C.Y. Cheng, F.C.N. Hong, Ultraviolet curing imprint lithography on flexible indium tin oxide substrates. J. Vac. Sci. Technol. B 24(3), 1377–1383 (2006). https://doi.org/10.1116/1.2200375

G.S.H.S. Ramkumar, S.A. Ramakrishna, J. Ramkumar, Excimer laser micromachining of indium tin oxide for fabrication of optically transparent metamaterial absorbers. Appl. Phys. A 125, 1–14 (2019). https://doi.org/10.1007/s0033

G. Račiukaitis, M. Brikas, M. Gedvilas, T. Rakickas, Patterning of indium–tin oxide on glass with picosecond lasers. Appl. Surf. Sci. 253(15), 6570–6574 (2007). https://doi.org/10.1016/j.apsusc.2007.01.099

R. Pawlak, M. Tomczyk, P. Tabaka, M. Walczak, Optical properties of a polymer film substrate after laser ablation of transparent conductors. J. Phys. Conf. Ser. 1782(1), 12026 (2021). https://doi.org/10.1088/1742-6596/1782/1/012026

N. Farid, H. Chan, D. Milne, A. Brunton, G.M.O. Connor, Stress assisted selective ablation of ITO thin film by picosecond laser. Appl. Surf. Sci. 427, 499–504 (2018). https://doi.org/10.1016/j.apsusc.2017.08.232

R. Tanaka, T. Takaoka, H. Mizukami, T. Arai, Y. Iwai, Laser etching of indium tin oxide thin films by ultra-short pulsed laser, Fourth International Symposium on Laser Precision Microfabrication. SPIE 5063, 370–373 (2003). https://doi.org/10.1117/12.540533

Q. Bian, X. Yu, B. Zhao, Z. Chang, S. Lei, Femtosecond laser ablation of indium tin-oxide narrow grooves for thin film solar cells. Opt. Laser Technol. 45, 395–401 (2013). https://doi.org/10.1016/j.optlastec.2012.06.018

Y. Wang, B. Li, S. Li, H. Li, L. Huang, N. Ren, Parameter optimization in femtosecond pulsed laser etching of fluorine-doped tin oxide films. Opt. Laser Technol. 116, 162–170 (2019). https://doi.org/10.1016/j.optlastec.2019.03.031

A. Risch, R. Hellmann, Picosecond laser patterning of ITO thin films[J]. Phys. Procedia 12, 133–140 (2011)

S. Xiao, S.A. Fernandes, A. Ostendorf, Selective patterning of ITO on flexible PET substrate by 1064 nm picosecond laser[J]. Phys. Procedia 12, 125–132 (2011)

B. Kim, R. Iida, H.D. Doan, K. Fushinobu, Mechanism of TCO thin film removal process using near-infrared ns pulse laser: plasma shielding effect on irradiation direction. Int. J. Heat Mass Transfer 102, 77–85 (2016). https://doi.org/10.1016/j.ijheatmasstransfer.2016.06.009

H. Yang, Y. Cao, W. Xue et al., Ultraviolet laser patterning of fluorine-doped tin oxide with different radiation directions[J]. J. Russ. Laser Res. 40, 581–589 (2019)

C. McDonnell, D. Milne, H. Chan, D. Rostohar, G.M.O. Connor, Part 1: Wavelength dependent nanosecond laser patterning of very thin indium tin oxide films on glass substrates. Opt. Lasers Eng. 80, 73–82 (2016). https://doi.org/10.1016/j.optlaseng.2015.12.005

C. McDonnell, D. Milne, H. Chan, D. Rostohar, G.M.O. Connor, Part 2: Ultra-short pulse laser patterning of very thin indium tin oxide on glass substrates. Opt. Lasers Eng. 81, 70–78 (2016). https://doi.org/10.1016/j.optlaseng.2015.11.008

H.W. Choi, D.F. Farson, J. Bovatsek, A. Arai, D. Ashkenasi, Direct-write patterning of indium-tin-oxide film by high pulse repetition frequency femtosecond laser ablation. Appl. Opt. 46(23), 5792–5799 (2007). https://doi.org/10.1364/ao.46.005792

H. Tsai, H. Yang, C. Pan, M. Chou, Laser patterning indium tin oxide (ITO) coated on PET substrate. Proc. SPIE 4230, 156–163 (2000). https://doi.org/10.1117/12.404897

C. McDonnell, D. Milne, C. Prieto, H. Chan, D. Rostohar, G.M.O. Connor, Laser patterning of very thin indium tin oxide thin films on PET substrates. Appl. Surf. Sci. 359, 567–575 (2015). https://doi.org/10.1016/j.apsusc.2015.10.019

G. Singh, H. Sheokand, S. Ghosh et al., Excimer laser micromachining of indium tin oxide for fabrication of optically transparent metamaterial absorbers[J]. Appl. Phys. A 125, 1–14 (2019). https://doi.org/10.1007/s00339-018-2013-7

S.S. Pesetski, O.V. Filimonov, V.N. Koval et al., Structural features and relaxation properties of PET/PC blends containing impact strength modifier and chain extender[J]. Express Polym LettPolym. Lett. 3, 606–614 (2009). https://doi.org/10.3144/expresspolymlett.2009.76

J.M. Liu, Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt. Lett. 7(5), 196–198 (1982). https://doi.org/10.1364/ol.7.000196

P.T. Mannion, J. Magee, E. Coyne, G.M.O. Connor, T.J. Glynn, The effect of damage accumulation behavior on ablation thresholds and damage morphology in ultrafast laser micro-machining of common metals in air. Appl. Surf. Sci. 233(1–4), 275–287 (2004). https://doi.org/10.1016/j.apsusc.2004.03.229

C. McDonnell, Pulsed laser material interaction with thin indium tin oxide films, College of Science, National University of Ireland Galway. (2015). https://doi.org/10.13140/RG.2.2.22636.77445.

O. Yavas, M. Takai, Effect of substrate absorption on the efficiency of laser patterning of indium tin oxide thin films[J]. J. Appl. Phys. 85(8), 4207–4212 (1999). https://doi.org/10.1063/1.370332

M. Gugliotti, M.S. Baptista, M.J. Politi, Surface tension gradients induced by temperature: the thermal Marangoni effect[J]. J. Chem. Educ. 81(6), 824 (2004). https://doi.org/10.1002/abio.370040210

L. Huang, B. Li, N. Ren, Enhancing optical and electrical properties of Al-doped ZnO coated polyethylene terephthalate substrates by laser annealing using overlap rate controlling strategy. Ceramics Int. 42(6), 7246–7252 (2016). https://doi.org/10.1016/j.ceramint.2016.01.118

C. Huang, C. Guan, B. Lin, S. Huang, B. Huang, W. Su, L. Xu, Effect of laser scribing on coating, drying, and crystallization of absorber layer of perovskite solar cells. Solar RRL 7(4), 2200945 (2023). https://doi.org/10.1002/solr.202200945

Acknowledgements

The authors appreciate the financial support from the National Key Research and Development Program of China (No. 2019YFA0709102).

Author information

Authors and Affiliations

Contributions

FW: conceptualization, methodology, data curation, writing—original draft. YY: resources, funding acquisition, conceptualization, methodology, project administration, supervision, writing—review and editing. QM: investigation, validation, writing—review and editing. PZ: funding acquisition, conceptualization, project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, F., Yan, Y., Mu, Q. et al. Laser rear-side ablation mechanism for ITO removal on PET substrate. Appl. Phys. A 130, 186 (2024). https://doi.org/10.1007/s00339-024-07351-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-024-07351-8