Abstract

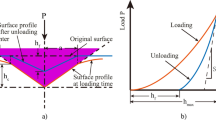

To investigate the effect of γ/γʹ interface on the nano-deformation of the workpiece during nanoindentation of nickel-based single crystal alloys, a two-phase model of γ phase doped with Cr and Co elements was simulated using a molecular dynamics approach with controlling the indenter displacement. It is found that: in the early stage of loading, the load increases gradually with the increase of loading depth; when the indenter is close to the interface, the load is affected by the interface and changes abruptly, generating a great value; after the indenter breaks through the interface, the load fluctuates and becomes larger. More Stair-rod dislocations and Hirth dislocations are generated at the interface, and these dislocations, together with some dislocation nodes, strengthen the matrix dislocations to enhance the deformation resistance of the workpiece. In addition, atomic displacement, strain transfer, and defect development are discontinuous during the movement of the γ phase to the γʹ phase. In particular, the displaced atom morphology in the γʹ phase evolves from triangular to filleted corner, reflecting the inhibitory effect of the boundary on the development of the plastic deformation region.

Graphical abstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

References

P. Zhang, Y. Yuan, S.C. Shen, B. Li, R.H. Zhu, G.X. Yang, X.L. Song, Tensile deformation mechanisms at various temperatures in a new directionally solidified Ni-base superalloy. J. Alloys Compd. 694, 502–509 (2017). https://doi.org/10.1016/j.jallcom.2016.09.303

X. Liu, J. Fan, P. Zhang, J. Xie, F. Chen, D. Liu, R. Yuan, B. Tang, H. Kou, J. Li, Temperature dependence of deformation behavior, microstructure evolution and fracture mechanism of Inconel 625 superalloy. J. Alloys Compd. (2021). https://doi.org/10.1016/j.jallcom.2021.159342

X. Ai, L. Shi, F. Luo, H. Pei, Z. Wen, Thermomechanical fatigue of Nickel-Based Single-Crystal superalloys. Eng. Fract. Mech. (2023). https://doi.org/10.1016/j.engfracmech.2023.109262

H. Long, S. Mao, Y. Liu, Z. Zhang, X. Han, Microstructural and compositional design of Ni-based single crystalline superalloys: a review. J. Alloys Compd. 743, 203–220 (2018). https://doi.org/10.1016/j.jallcom.2018.01.224

J. Wang, J. Liang, Z. Wen, Z. Yue, Y. Peng, Unveiling the local deformation behavior of typical microstructures of nickel-based single crystals under nanoindentation. Mech. Mater. (2022). https://doi.org/10.1016/j.mechmat.2021.104204

S. Gautham, S. Sasmal, Determination of fracture toughness of nano-scale cement composites using simulated nanoindentation technique. Theor. Appl. Fract. Mech. 103, 102275 (2019). https://doi.org/10.1016/j.tafmec.2019.102275

W. Zhang, Z. Ma, D. Liu, S. Wang, H. Zhao, L. Ren, Synergetic strengthening of coherent and incoherent interface on a mixed-phase high-entropy alloy revealed by micro-pillar compression. J. Mater. Res. Technol. 18, 3777–3784 (2022). https://doi.org/10.1016/j.jmrt.2022.04.064

X. Lu, Y. Ma, D. Peng, R. Johnsen, D. Wang, In situ nanomechanical characterization of hydrogen effects on nickel-based alloy 725 under different metallurgical conditions. J. Mater. Sci. Technol. 135, 156–169 (2023). https://doi.org/10.1016/j.jmst.2022.07.006

S. Liang, W. Yan, Study on the micro-structure and the nano-indentation responses of laser solid formed epitaxial Ni-based superalloy. J. Alloys Compd. 921, 166091 (2022). https://doi.org/10.1016/j.jallcom.2022.166091

R. M’Saoubi, D. Axinte, C. Herbert, M. Hardy, P. Salmon, Surface integrity of nickel-based alloys subjected to severe plastic deformation by abusive drilling. CIRP Ann. 63, 61–64 (2014). https://doi.org/10.1016/j.cirp.2014.03.067

M. Göken, M. Kempf, Microstructural properties of superalloys investigated by nanoindentations in an atomic force microscope. Acta Mater. 47, 1043–1052 (1999). https://doi.org/10.1016/s1359-6454(98)00377-2

X. Ji, G. Xiao, W. Zhao, P. Lv, Y. Zhao, X. Jin, X. Fan, Loading rate sensitivity of nickel-based single crystal superalloys characterized by nanoindentation. Int. J. Solids Struct. 234, 111272 (2022). https://doi.org/10.1016/j.ijsolstr.2021.111272

S. Huang, C. Zhou, Modeling and simulation of nanoindentation. Jom 69, 2256–2263 (2017). https://doi.org/10.1007/s11837-017-2541-1

M. Liu, Q. Zheng, X. Wang, C. Xu, Characterization of distribution of residual stress in shot-peened layer of nickel-based single crystal superalloy DD6 by nanoindentation technique. Mech. Mater. 164, 104143 (2022). https://doi.org/10.1016/j.mechmat.2021.104143

Z. Zhu, H. Huang, S. Min, J. Hou, W. Ji, Characterization of microstructure and hardening of SLM nickel-based alloy irradiated by He ions. J. Nucl. Mater. 566, 153794 (2022). https://doi.org/10.1016/j.jnucmat.2022.153794

S.Z. Chavoshi, S. Xu, Nanoindentation/scratching at finite temperatures: Insights from atomistic-based modeling. Prog. Mater. Sci. 100, 1–20 (2019). https://doi.org/10.1016/j.pmatsci.2018.09.002

L. Kurpaska, F.J. Dominguez-Gutierrez, Y. Zhang, K. Mulewska, H. Bei, W.J. Weber, A. Kosińska, W. Chrominski, I. Jozwik, R. Alvarez-Donado, Effects of Fe atoms on hardening of a nickel matrix: Nanoindentation experiments and atom-scale numerical modeling. Mater. Des. 217, 110639 (2022). https://doi.org/10.1016/j.matdes.2022.110639

B. Yang, B. Zheng, X. Hu, K. Zhang, Y. Li, P. He, Z. Yue, Atomistic simulation of nanoindentation on incipient plasticity and dislocation evolution in γ/γ′ phase with interface and void. Comput. Mater. Sci. 114, 172–177 (2016). https://doi.org/10.1016/j.commatsci.2015.12.021

J. Zhou, Y. He, J. Shen, F. Essa, J. Yu, Ni/Ni3Al interface-dominated nanoindentation deformation and pop-in events. Nanotechnology 33, 105703 (2021). https://doi.org/10.1088/1361-6528/ac3d62

Y. Zhu, Z. Li, M. Huang, Atomistic modeling of the interaction between matrix dislocation and interfacial misfit dislocation networks in Ni-based single crystal superalloy. Comput. Mater. Sci. 70, 178–186 (2013). https://doi.org/10.1016/j.commatsci.2012.10.037

X. Feng, Z. Zhu, Z. Wu, M. Zheng, W. Chen, X. Wei, Atomic-scale study of the repeated friction processes of γ/γʹphase nickel-based single crystal alloys. Tribol. Int. 185, 108538 (2023). https://doi.org/10.1016/j.triboint.2023.108538

J. Hao, X. Jing, B. Liu, Y. Wang, Z. Wang, W. He, W. Zhao, L. Feng, Molecular dynamics simulations on shock induced plasticity and stacking fault of coherent 001 Ni/Ni3Al laminate composite. J. Mater. Res. Technol. 18, 4930–4945 (2022). https://doi.org/10.1016/j.jmrt.2022.04.074

Y.B. Zhao, X. Peng, T. Fu, R. Sun, C. Feng, Z. Wang, MD simulation of nanoindentation on (001) and (111) surfaces of Ag–Ni multilayers. Physica E 74, 481–488 (2015). https://doi.org/10.1016/j.physe.2015.08.020

H. Xiang, H. Li, T. Fu, Y. Zhao, C. Huang, G. Zhang, X. Peng, Molecular dynamics simulation of AlN thin films under nanoindentation. Ceram. Int. 43, 4068–4075 (2017). https://doi.org/10.1016/j.ceramint.2016.11.218

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995). https://doi.org/10.1006/jcph.1995.1039

A. Stukowski, Visualization and analysis of atomistic simulation data with OVITO–the open visualization tool. Modell. Simul. Mater. Sci. Eng. 18, 015012 (2009). https://doi.org/10.1088/0965-0393/18/1/015012

E.W. Ross, K.S. O’Hara, René N4: a first generation single crystal turbine airfoil alloy with improved oxidation resistance, low angle boundary strength and superior long time rupture strength. Superalloys 1996, 19–25 (1996). https://doi.org/10.7449/1996/SUPERALLOYS_1996_19_25

E. Lemoine, D. Nélias, F. Thouverez, C. Vincent, Influence of fretting wear on bladed disks dynamic analysis. Tribol. Int. 145, 106148 (2020). https://doi.org/10.1016/j.triboint.2019.106148

Y. Wang, S. Tang, J. Guo, Molecular dynamics study on deformation behaviour of monocrystalline GaN during nano abrasive machining. Appl. Surf. Sci. 510, 145492 (2020). https://doi.org/10.1016/j.apsusc.2020.145492

S. Nosé, A unified formulation of the constant temperature molecular dynamics methods. J. Chem. Phys. 81, 511–519 (1984). https://doi.org/10.1063/1.447334

S.J. Watowich, E.S. Meyer, R. Hagstrom, R. Josephs, A stable, rapidly converging conjugate gradient method for energy minimization. J. Comput. Chem. 9, 650–661 (1988). https://doi.org/10.1002/jcc.540090611

P. Wang, W. Wu, F. Cui, X. Yang, A. Pan, Investigation of thermal and mechanical effects during electrically-assisted compression of CoCrFeNiW0 5 high entropy alloy. Mater Charact 202, 112981 (2023). https://doi.org/10.1016/j.matchar.2023.112981

Y. Kurniawan, C.L. Petrie, K.J. Williams, M.K. Transtrum, E.B. Tadmor, R.S. Elliott, D.S. Karls, M. Wen, Bayesian, frequentist, and information geometric approaches to parametric uncertainty quantification of classical empirical interatomic potentials. J. Chem. Phys. (2022). https://doi.org/10.1063/5.0084988

A. Aghajamali, C. de Tomas, I. Suarez-Martinez, N.A. Marks, Unphysical nucleation of diamond in the extended cutoff Tersoff potential. Mol. Simul. 44, 164–171 (2018). https://doi.org/10.1080/08927022.2017.1355555

J. Du, C. Wang, T. Yu, Construction and application of multi-element EAM potential (Ni–Al–Re) in γ/γ′ Ni-based single crystal superalloys. Modell. Simul. Mater. Sci. Eng. 21, 015007 (2012). https://doi.org/10.1088/0965-0393/21/1/015007

Q.N. Fan, C.Y. Wang, T. Yu, J.P. Du, A ternary Ni–Al–W EAM potential for Ni-based single crystal superalloys. Physica B 456, 283–292 (2015). https://doi.org/10.1016/j.physb.2014.09.012

O.R. Deluigi, R.C. Pasianot, F. Valencia, A. Caro, D. Farkas, E.M. Bringa, Simulations of primary damage in a high entropy alloy: probing enhanced radiation resistance. Acta Mater. 213, 116951 (2021). https://doi.org/10.1016/j.actamat.2021.116951

J. Tersoff, Modeling solid-state chemistry: Interatomic potentials for multicomponent systems. Phys. Rev. B 39, 5566 (1989). https://doi.org/10.1103/physrevb.39.5566

S. Foiles, M. Baskes, M.S. Daw, Embedded-atom-method functions for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, and their alloys. Phys. Rev. B 33, 7983 (1986). https://doi.org/10.1103/physrevb.33.7983

Z. Hao, R. Cui, Y. Fan, J. Lin, Diffusion mechanism of tools and simulation in nanoscale cutting the Ni–Fe–Cr series of Nickel-based superalloy. Int. J. Mech. Sci. 150, 625–636 (2019). https://doi.org/10.1016/j.ijmecsci.2018.10.058

G. Bonny, D. Terentyev, R.C. Pasianot, S. Poncé, A. Bakaev, Interatomic potential to study plasticity in stainless steels: the FeNiCr model alloy. Modell. Simul. Mater. Sci. Eng. 19, 085008 (2011). https://doi.org/10.1088/0965-0393/19/8/085008

Y.M. Kang, N.X. Chen, J. Shen, Atomistic simulation of the lattice constants and lattice vibrations in RT4Al8 (R= Nd, Sm; T= Cr, Mn, Cu, Fe). J. Alloys Compd. 352, 26–33 (2003). https://doi.org/10.1016/s0925-8388(02)01134-9

A. Stukowski, V.V. Bulatov, A. Arsenlis, Automated identification and indexing of dislocations in crystal interfaces. Modell. Simul. Mater. Sci. Eng. 20, 085007 (2012). https://doi.org/10.1088/0965-0393/20/8/085007

D. Bürger, A. Dlouhý, K. Yoshimi, G. Eggeler, How nanoscale dislocation reactions govern low-temperature and high-stress creep of Ni-base single crystal superalloys. Crystals 10, 134 (2020). https://doi.org/10.3390/cryst10020134

L. Dupuy, M. Fivel, A study of dislocation junctions in FCC metals by an orientation dependent line tension model. Acta Mater. 50, 4873–4885 (2002). https://doi.org/10.1016/s1359-6454(02)00356-7

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 52265025), the Open Project of State Key Laboratory of Solid Lubrication (LSL-2215), and the Gansu Provincial Natural Science Foundation (23JRRA811).

Author information

Authors and Affiliations

Contributions

ZZ: Writing–original draft, Formal analysis. HZ: Data curation, Visualization. YX: Investigation, Conceptualization. DQ: Validation, Supervision. XW: Methodology, Resources, Supervision. MZ: Investigation, Formal analysis.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical statement

We declare that our paper has not been submitted or published elsewhere; All data in this paper are true and reliable, and the main data and charts have not been published; This article does not contain plagiarism or infringement of others' intellectual property rights; This study does not involve human or animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, Z., Zhang, H., Xu, Y. et al. Molecular dynamics study of the γ/γʹ interface influencing the nano-deformation of nickel-based single crystal alloys during nanoindentation process. Appl. Phys. A 130, 111 (2024). https://doi.org/10.1007/s00339-024-07281-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-024-07281-5