Abstract

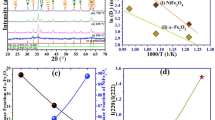

This study introduces a novel Ni3Si/Fe3O4@polyvinylidene fluoride (PVDF) composite, which is fabricated using a lamellar Ni3Si template under pulsed magnetic fields. The results reveal that increasing the content of Fe3O4 nanoparticles (NPs) enhances the densification of Fe3O4@PVDF slurries within the Ni3Si template. Interestingly, the ferromagnetic behavior of the Ni3Si/Fe3O4@PVDF composites shows an opposite trend to that of the Fe3O4@PVDF slurry as the magnetic flux density peak (MP) increases. Specifically, the maximum magnetization (Mmax) values achieved are 2.99 × 10–2, 2.79 × 10–2, 2.36 × 10–2, and 2.02 × 10–2 emu/g at MP values of 0, 4.5, 5.7, and 8.9 T, respectively. The influence of magnetic fields becomes more pronounced with higher Fe3O4 NPs content. However, when the Fe3O4 NPs content reaches 9.1% and the MP is 8.9 T, the uncertainty regarding the actual content of Fe3O4 NPs filled into the Ni3Si template poses challenges for the regulation of magnetic properties. Therefore, a lower Fe3O4 NPs content is more advantageous for controlling the magnetic properties of Ni3Si/Fe3O4@PVDF composites.

Similar content being viewed by others

Data availability

The raw data required to reproduce these findings are available at authors and can be shared upon request.

References

W.J. Li, W.C. Li, J.K. Wu, X.F. Han, Y. Ying, J. Yu, J.W. Zheng, L. Qiao, J. Li, S.L. Che, Mat. Sci. Eng. B 291, 116387 (2023). https://doi.org/10.1016/j.mseb.2023.116387

R. Sankaranarayanan, S. Shailajha, S. Seema, M.S. Kairon Mubina, Appl. Phys. A Phys. A 129, 262 (2023). https://doi.org/10.1007/s00339-023-06561-w

R.K. Veena, A. Anand, M.M. Devi, V.S. Veena, J. Cyriac, N. Kalarikkal, S. Sagar, Appl. Phys. A 129, 598 (2023). https://doi.org/10.1007/s00339-023-06864-y

H. Oraby, H.R. Tantawy, M.A. Correa-Duarte, M. Darwish, A. Elsaidy, I. Naeem, M.H. Senna, Nanomaterials 12, 2805 (2022). https://doi.org/10.3390/nano12162805

G.M. Ispas, I. Craciunescu, S. Porav, R. Turcu, D. Gligor, Int. J. Environ. An. Ch. 103, 3483 (2023). https://doi.org/10.1080/03067319.2021.1910249

C.N. Pinotti, L.M. de Souza, W.P. Marques, J.R.C. Proveti, H.C. Jesus, J.C.C. Freitas, P.S.S. Porto, E.P. Muniz, E.C. Passamani, Mater. Chem. Phys. 277, 125368 (2022). https://doi.org/10.1016/j.matchemphys.2021.125368

L.S. Li, R.M. Erb, J.J. Wang, J. Wang, Y.M. Chiang, Adv. Energy Mater. 9, 1802472 (2019). https://doi.org/10.1002/aenm.201802472

C. Kim, Y. Yang, D.H. Lopez, D. Ha, Appl. Phys. Lett. 117, 123903 (2020). https://doi.org/10.1063/5.0016456

Q.Y. Shi, T.Y. Liu, S. Song, J.L. Wang, M.Q.H. Meng, I.E.E.E.T. Instrum, Meas. 70, 4003009 (2021). https://doi.org/10.1109/TIM.2021.3053056

L.J. Zhao, C.M. Zhang, W.J. Zhang, Y.S. Shi, L.Y. Xia, W.L. Zhang, B. Peng, X.J. Jin, C.Y. Tian, F. Luan, A.C.S. Appl, Nano Mater. 4, 12920 (2021). https://doi.org/10.1021/acsanm.1c02996

C.L. Alves, J.S. Oliveira, A. Tannus, A. Tarpani, J.R. Tarpani, Materials 14, 977 (2021). https://doi.org/10.3390/ma14040977

P. Tan, Y. Jiang, X.Q. Liu, L.B. Sun, Chin. J. Chem. Eng. 27, 1324 (2019). https://doi.org/10.1016/j.cjche.2018.11.004

F.F. Lu, A.Q. Dong, G.J. Ding, K. Xu, J.M. Li, L.J. You, J. Mol. Liq. 294, 111515 (2019). https://doi.org/10.1016/j.molliq.2019.111515

C.E. Arinzechukwu, S.O. Aisida, A. Agbogu, I. Ahmad, F.I. Ezema, Appl. Phys. A 128, 1088 (2022). https://doi.org/10.1007/s00339-022-06248-8

X.Y. Qi, Z.Y. Chang, G.Q. Fu, T.F. Chen, Nanotechnology 32, 105101 (2021). https://doi.org/10.1088/1361-6528/abc781

S.M. Yu, X.G. Liu, G.J. Xu, Y. Qiu, L.L. Cheng, Desalin. Water Treat. 57, 16943 (2016). https://doi.org/10.1080/19443994.2015.1083892

T. Charoensuk, W. Thongsamrit, C. Ruttanapun, P. Jantaratana, C. Sirisathitkul, Nanomaterials 11, 558 (2021). https://doi.org/10.3390/nano11030558

Y.L. Zhang, X.A. Fan, W.T. Hu, Z.G. Luo, Z.J. Yang, G.Q. Li, Y.W. Li, J. Magn. Magn. Mater. 514, 167295 (2020). https://doi.org/10.1016/j.jmmm.2020.167295

P.A. Anggoro, T.E. Saraswati, W.W. Raharjo, J. Phys. Conf. 2190, 012024 (2022). https://doi.org/10.1088/1742-6596/2190/1/012024

J. Wang, W. Xiong, L. Huang, Y.X. Li, Z.L. Zuo, X.Y. Hu, T. Wang, J.Q. Xiao, J. Hu, Phys. B 567, 113 (2019). https://doi.org/10.1016/j.physb.2018.11.040

Q.S. Zhu, R.J. Tang, F. Peng, S.C. Xu, G.Q. Liang, R. Zhao, Y. Fang, L. You, X.D. Su, Phys. Rev. Appl. 16, 054006 (2021). https://doi.org/10.1103/PhysRevApplied.16.054006

Z.B. Li, Y. Li, Z.X. Zhang, Y.L. Liu, Y.F. Li, X.F. Zhang, AIP Adv. 9, 075109 (2019). https://doi.org/10.1063/1.5097271

Y.B. Dong, L. Zhu, B. Yin, X.R. Zhu, D.F. Li, Dalton T. 50, 17328 (2021). https://doi.org/10.1039/d1dt02925h

Z.F. Shang, M. Yue, Y.Q. Li, D.T. Zhang, Z.H. Xie, Y.Q. Wang, J. Magn. Magn. Mater. 502, 166484 (2020). https://doi.org/10.1016/j.jmmm.2020.166484

C. Vivès, J. Cryst. Growth 173, 541 (1997). https://doi.org/10.1016/S0022-0248(96)01051-2

J.A. Gavira, J.M. Garcia-Ruiz, Cryst. Growth Des. 9, 2610 (2009). https://doi.org/10.1021/cg8008688

L. Hu, X.Y. Feng, L.Z. Wei, K.J. Zhang, J.M. Dai, Y.C. Wu, Q.Q. Chen, Nanoscale 7, 10925 (2015). https://doi.org/10.1039/c5nr02498f

M.Y. Zhu, Y.M. Hu, Y. Li, H.M. Jin, Z.Z. Zhu, Phys. Stat. Sol. C 9, 122 (2012). https://doi.org/10.1002/pssc.201084200

D. Hippo, Y. Nakamine, K. Urakawa, Y. Tsuchiya, H. Mizuta, N. Koshida, S. Oda, JPN. J. Appl. Phys. 47, 7398 (2008). https://doi.org/10.1143/JJAP.47.7398

S. Xiong, Q. Wang, Y. Chen, J. Appl. Polym. Sci. 111, 963 (2010). https://doi.org/10.1002/app.29096

I.A. Kalinin, A.D. Davydov, K.S. Napolskii, A. Sobolev, M. Shatalov, M. Zinigrad, D. Bograchev, Electrochem. Commun. 149, 107469 (2023). https://doi.org/10.1016/j.elecom.2023.107469

Y.S. Li, N.J. Zhou, X. He, S. Zhang, D.Z. Zhu, Z.J. Ma, A.C.S. Appl, Electron. Mater. 5, 155 (2023). https://doi.org/10.1021/acsaelm.2c01179155

L.F. Wei, Z.L. Zhao, J.J. Gao, K. Cui, J. Electrochem. Soc. Electrochem. Soc. 164, E332 (2017). https://doi.org/10.1149/2.0831712jes

K. Cui, L. Yuan, Z. Zhao, Mat. Sci. Eng. B 290, 116330 (2023). https://doi.org/10.1016/j.mseb.2023.116330

K. Cui, L. Yuan, Z. Zhao, J. Magn. Magn. Mater. 563, 169972 (2022). https://doi.org/10.1016/j.jmmm.2022.169972

K. Cui, Z.L. Zhao, W.B. Liu, Electroanal. Chem.. Chem. 865, 114146 (2020). https://doi.org/10.1016/j.jelechem.2020.114146

K. Cui, Z.L. Zhao, Y. Tie, C. Li, L.F. Wei, Mater. Chem. Phys.. Chem. Phys. 281, 125957 (2022). https://doi.org/10.1016/j.matchemphys.2022.125957

Acknowledgements

Authors acknowledge the financial support from the Natural Science Foundation of Henan Province (No. 232300421321) and Natural Science Basic Research Program of Shaanxi (No. 2021JZ-10).

Author information

Authors and Affiliations

Contributions

KC: conceptualization, methodology, supervision, writing-original draft preparation. YC, YY and GS: visualization, investigation, validation. ZZ: writing—review and editing, funding acquisition, HL: writing—review and editing, supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cui, K., Cao, Y., Yang, Y. et al. Enhancing magnetic properties of Ni3Si/Fe3O4@PVDF composites via lamellar Ni3Si template fabrication under pulsed magnetic fields. Appl. Phys. A 129, 729 (2023). https://doi.org/10.1007/s00339-023-07018-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-07018-w