Abstract

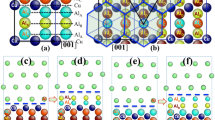

To investigate the compression and deformation behavior of nano-polycrystalline Cu/Al2Cu/Al-layered composites, it was constructed and analyzed using molecular dynamics simulation (MD). The findings indicate that The Cu/Al2Cu/Al materials exhibit sensitivity to changes in the interfacial layer d due to the asymmetry between tensile and compressive deformations. The compressive strain strengthening of the nano-polycrystalline Cu/Al2Cu/Al-layered composites increases as the interfacial layer d increases. During the tensile process, an increase in interfacial layer d leads to an increase in Young's modulus, while the fracture strength and fracture strain first increase and then decrease. The interfacial layer with a value of d = 4.88 nm promotes the delocalization of strain during the tensile and compressive deformation of nano-polycrystalline Cu/Al2Cu/Al materials. It facilitates cooperative deformation behavior between components, leading to improved toughness and strength of the materials.

Similar content being viewed by others

Data and code availability

The data that support the findings of this study are available from the corresponding author (Aiqin Wang) upon reasonable request.

References

W.N. Kim, S.I. Hong et al., Interactive deformation and enhanced ductility of tri-layered Cu/Al/Cu clad composite. Mater. Sci. Eng. A. 651, 976–986 (2016)

H. Yu, L. Zhang, F. Cai et al., Interface microstructure and growth mechanism of brazing Cu/Al joint with BAl88Si filler metal. Vacuum 181, 109641 (2020)

L. Marín, B. Warot-Fonrose, A. Estève et al., Self-organized Al2Cu nanocrystals at the interface of aluminum-based reactive nanolaminates to lower reaction onset temperature. ACS Appl. Mater. Interfaces 8, 13104–13113 (2016)

R. Kocich, L. Kunčická, P. Král et al., Characterization of innovative rotary swaged Cu-Al clad composite wire conductors. Mater. Des. 160, 828–835 (2018)

G. Liu, Q. Wang, L. Zhang et al., Effects of melt-to-solid volume ratio and pouring temperature on microstructures and mechanical properties of Cu/Al bimetals in compound casting process. Metall. Mater. Trans. A 50, 401–414 (2019)

E. Hug, N. Bellido et al., Brittleness study of intermetallic (Cu, Al) layers in copper-clad aluminium thin wires. Mater. Sci. Eng. A 528, 7103–7106 (2011)

L. Kunčická, R. Kocich, K. Dvořák et al., Rotary swaged laminated Cu–Al composites: effect of structure on residual stress and mechanical and electric properties. Mater. Sci. Eng. A 742, 743–750 (2019)

P. Bazarnik, A. Bartkowska, B. Romelczyk-Baishya, B. Adamczyk-Cieślak, J. Dai et al., Superior strength of tri-layered Al–Cu–Al nano-composites processed by high-pressure torsion. J. Alloys Compd. 846, 156380 (2020)

H. Li, Y. Yang, X. Liang et al., Effect of annealing temperature and time on the microstructure, mechanical properties and conductivity of cold-rolled explosive Cu/Al composite sheets. Mater. Res. Express. 7, 106502 (2020)

M. Ebrahimi, G. Liu, C. Li, Q. Wang, H. Jiang, W. Ding, F. Su et al., Experimental and numerical analysis of Cu/Al8011/Al1060 trilayered composite: a comprehensive study. J. Mater. Res. Technol. 9, 14695–14707 (2020)

W. Jiang, F. Guan, G. Li et al., Processing of Al/Cu bimetal via a novel compound casting method. Mater. Manuf. Process. 34, 1016–1025 (2019)

Y. Wang, R. Song, J. Yanagimoto et al., Effect of heat treatment on bonding mechanism and mechanical properties of high strength Cu/Al/Cu clad composite. J. Alloys Compd. 801, 573–580 (2019)

L. Wang, Q. Du, C. Li et al., Enhanced mechanical properties of lamellar Cu/Al composites processed via high-temperature accumulative roll bonding. Trans. Nonferrous Met. Soc. China. 29, 1621–1630 (2019)

D. Chang, P. Wang, Y. Zhao et al., Effects of asymmetry and annealing on interfacial microstructure and mechanical properties of Cu/Al laminated composite fabricated by asymmetrical roll bonding. J. Alloys Compd. 815, 152453 (2020)

J. Li, H. Gao, C. Kong et al., Insight into the bonding mechanism in Cu/Al/Cu clad sheets via introduction of thin SUS304 interlayer. J. Mater. Res. Technol. 21, 4619–4635 (2022)

B. Ji, J. Cao, M. Yu et al., Application of laser ultrasonic for detecting delamination in Cu/Al composites. Optik 243, 167426 (2021)

H. Huang, Y. Dong, M. Yan et al., Evolution of bonding interface in solid–liquid cast-rolling bonding of Cu/Al clad strip. Trans. Nonferrous Met. Soc. China 27, 1019–1025 (2017)

S.Y. Liu, A.Q. Wang, S.J. Lu et al., High-performance Cu/Al laminated composites fabricated by horizontal twin-roll casting: Horizontales Gießwalzen von laminiertem Hochleistungs-Cu/Al-Verbundwerkstoff. Mater. Werkst. 49, 1213–1223 (2018)

H. Zhang, A.Q. Pan, R. Hei et al., An atomistic simulation on the tensile and compressive deformation mechanisms of nano-polycrystalline Ti. Appl. Phys. A Mater. 127, 1–7 (2021)

W.J. Lee, H.L. Chen, J.Y. Hsieh et al., Investigation of the fracture mechanism of Cu–Al gradient structure. RSC Adv. 4(23), 11975–11979 (2014)

R. Li, H.B. Chew et al., Closed and open-ended stacking fault tetrahedra formation along the interfaces of Cu–Al nanolayered metals. Philos. Mag. 95(25), 2747–2763 (2015)

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995)

A. Stukowski, Structure identification methods for atomistic simulations of crystalline materials. Model. Simul. Mater. Sci. Eng. 20, 045021 (2012)

P. Hirel, Atomsk: a tool for manipulating and converting atomic data files. Comput. Phys. Commun. 197, 212–219 (2015)

N. Nouri, V. Ziaei-Rad, S. Ziaei-Rad et al., An approach for simulating microstructures of polycrystalline materials. Comput. Mech. 52, 181–192 (2013)

X.W. Zhou, D.K. Ward, M.E. Foster et al., An analytical bond-order potential for the aluminum copper binary system. J. Alloys Compd. 680, 752–767 (2016)

M. Parrinello, A. Rahman et al., Polymorphic transitions in single crystals: a new molecular dynamics method. J. Appl. Phys. 52, 7182–7190 (1981)

F. Zhang, J.Q. Zhou et al., Tension-compression asymmetry and twin boundaries spacings effects in polycrystalline Ni nanowires. J. Appl. Phys. 120, 044303 (2016)

X. Chen, W. Chen, Y. Ma, Y. Zhao, C.Y. Deng, X.H. Peng, T. Fu et al., Tension-compression asymmetry of single-crystalline and nanocrystalline NiTi shape memory alloy: an atomic scale study. Mech. Mater. 145, 103402 (2020)

Acknowledgements

We appreciate the financial support of the National Natural Science Foundation of China (Grant no. 52271131) and Key R&D and Promotion Project of Henan Province (no. 232102231006).

Author information

Authors and Affiliations

Contributions

XB performed the data analyses and wrote the manuscript; AW contributed to the conception of the study; JX helped perform the analysis with constructive discussions; PL contributed significantly to analysis and manuscript preparation; ZM and ZL contributed greatly to the collection and collation of data.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bian, X., Wang, A., Xie, J. et al. The tensile and compressive deformation mechanisms of the Cu/Al2Cu/Al-layered composites via molecular dynamics simulation. Appl. Phys. A 129, 719 (2023). https://doi.org/10.1007/s00339-023-07002-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-07002-4