Abstract

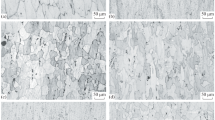

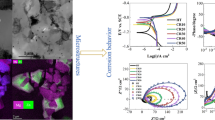

The influence laws of two different rolling processes on the microstructures and properties of 6016 aluminum alloys in rolling, T4, T4P states, and aging are studied, respectively. The microstructures under different rolling processes are also analyzed by X-ray diffraction (XRD), scanning electron microscope (SEM), transmission electron microscope (TEM) and electron backscatter diffraction (EBSD). The results indicate that during the cold rolling process, compared with B alloy, A alloy generated small initial grains. The small initial grains will increase the deformation resistance, and the strength and hardness of A alloy are better after rolling, but with poor plasticity. After solution treatment, A alloy generated small grains with recrystallization, the hardness, plasticity, and formability of A alloy in T4 state are better than B alloy after solution treatment and natural aging. A alloy is more sensitive to aging response, and artificial aging occurs during the pre-aging process. The proportion of large Angle grain boundaries in A alloy is large but with small dislocation density, uneven distribution, and small texture content. This makes A alloy have better strength and hardness in T4P and poor plasticity and formability than B alloy after solution treatment, pre-aging and natural aging. However, the strength and hardness of A alloy are also smaller than that of alloy B after artificial aging.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Z. Zhan, Application situation and demand prospect of aluminum automobile body sheet. Nonferrous Metals Process. 41(06), 1–5+8 (2012). https://doi.org/10.3969/j.issn.1671-6795.2012.06.001

Y.P. Xu, Y.L. Ren, F. Li, X.S. Wei, E.J. Lu, Effect of dynamic cooling pre-ageing on bake hardening response of aluminum alloy 6016. Light Alloy Fabric. Technol. 46(10), 29–33 (2018). https://doi.org/10.13979/j.1007-7235.2018.10.005

X.J. Wang, W. Sun, J.F. Chen, F.Y. Wang, L. Li, J.Z. Cui, Microstructures and properties of 6016 aluminum alloy with gradient composition. Rare Met. 40(8), 2154–2159 (2021). https://doi.org/10.1007/s12598-020-01515-0

L. Ding, Z. Jia, Z. Zhang, R.E. Sanders, Q. Liu, G. Yang, The natural aging and precipitation hardening behavior of Al-Mg-Si-Cu alloys with different Mg/Si ratios and Cu additions. Mater. Sci. Eng., A 627, 119–126 (2015). https://doi.org/10.1016/j.msea.2014.12.086

M. Cui, Y.H. Jo, S.H. Kayani, H.W. Kim, J.H. Lee, Effects of Cu additions on the precipitation activation energy and mechanical properties of prestrained Al–Mg–Si alloys. J. Market. Res. 20, 2629–2637 (2022). https://doi.org/10.1016/j.jmrt.2022.08.037

R. Zang, Y. Ning, L. Ding, Z. Jia, K. Xiang, Q. Liu, Y. Li, Study on properties and precipitation behavior of 6000 series alloys with high Mg/Si ratios and Cu contents. Mater. Charact. 194, 112402 (2022). https://doi.org/10.1016/j.matchar.2022.112402

Y. Aruga, M. Kozuka, Y. Takaki, T. Sato, Effects of natural aging after pre-aging on clustering and bake-hardening behavior in an Al–Mg–Si alloy. Scripta Mater. 116, 82–86 (2016). https://doi.org/10.1016/j.scriptamat.2016.01.019

F.B. Zhang, X.J. Xu, Y. Luo, T. Song, Y.K. Zhang, Z.Q. Zhang, Research progress of microalloyed 6××× series aluminum alloys. Mater. Rep. 26(S1), 384–388 (2012)

Y. Jiang, F. Liu, Effects of Sc or/and Ge addition on microstructure and mechanical properties of as-cast 6016 Al alloy. J. Alloys Compd. 809, 151829 (2019). https://doi.org/10.1016/j.jallcom.2019.151829

L. Yan, Y. Zhang, X. Li, Z. Li, F. Wang, H. Liu, B. Xiong, Effect of Zn addition on microstructure and mechanical properties of an Al–Mg–Si alloy. Progress Nat. Sci. Mater. Int. 24(2), 97–100 (2014). https://doi.org/10.1016/j.pnsc.2014.03.003

D. Kong, A. Li, R. Yu, B. Lu, L. Wang, T. Zuo, S. Wei, Effects of Cu element and heat treatment process on microstructures and properties of 6016 aluminum alloy. J. Phys. Conf. Ser. 1635, 012021 (2020). https://doi.org/10.1088/1742-6596/1635/1/012021

X. Wu, Z.P. Guan, Z.Z. Yang, X. Wang, F. Qiu, H.Y. Wang, Effect of Cu content on central-segregation composition and mechanical properties of Al–Mg–Si alloys produced by twin-roll casting. Mater. Sci. Eng. A. 869, 144782 (2023). https://doi.org/10.1016/j.msea.2023.144782

H.J. Zhao, S.Y. Li, R.W. Zhan, Z.B. Yang, D. Ai, T.S. Deng, Y.W. Cao, Influence of graded quenching on natural aging and paint hardening of 6016 aluminum alloy. Heat Treat. Met. 43(08), 198–202 (2018). https://doi.org/10.13251/j.issn.0254-6051.2018.08.041

A. Ghosh, A. Roy, A. Ghosh, M. Ghosh, Influence of temperature on microstructure, crystallographic texture and mechanical properties of EN AW 6016 alloy during plane strain compression. Mater. Today Commun. 26, 101808 (2020). https://doi.org/10.1016/j.mtcomm.2020.101808

O. Engler, C.D. Marioara, Y. Aruga, M. Kozuka, O.R. Myhr, Effect of natural aging or pre-ageing on the evolution of precipitate structure and strength during age hardening of Al–Mg–Si alloy AA 6016. Mater. Sci. Eng. A 759, 520–529 (2019). https://doi.org/10.1016/j.msea.2019.05.073

X.P. Chen, L. Mei, D. Chen, Z.L. Bao, Q. Liu, The effect of initial aging treatment on the microstructure and mechanical properties of cryorolled 6016 Al alloy. Mater. Sci. Eng., A 667, 311–316 (2016). https://doi.org/10.1016/j.msea.2016.04.099

A.G. Mochugovskiy, N.Y. Tabachkova, M.E. Ghayoumabadi, V.V. Cheverikin, A.V. Mikhaylovskaya, Joint effect of quasicrystalline icosahedral and L12-structured phases precipitation on the grain structure and mechanical properties of aluminum-based alloys. J. Mater. Sci. Technol. 87, 196–206 (2021). https://doi.org/10.1016/j.jmst.2021.01.055

J.X. Zhang, Q.K. Yue, K.L. Zhang, Y.J. Zhao, Effect of solution treatment on microstructure and texture of 6016 aluminum alloy cold-rolled sheet. Hot Work. Technol. 46(10), 228–232 (2017). https://doi.org/10.14158/j.cnki.1001-3814.2017.10.061

X.G. Duan, H.T. Jiang, Z.L. Mi, L.L. Wang, X. Li, Effect of rolling method on microstructure and plastic anisotropy of 6016 aluminum alloy sheet. J. Mater. Eng. 48(08), 134–141 (2020). https://doi.org/10.11868/j.issn.1001-4381.2019.000766

Z.Y. Long, G.C. Yuan, C. Cheng, Effect of pretreatment on formability of asynchronously rolled 6016 aluminum alloy sheet. Heat Treat. Metals 45(12), 76–81 (2020). https://doi.org/10.13251/j.issn.0254-6051.2020.12.014

W.H. Liu, Q. Qiu, Y.Q. Chen, C.P. Tang, X. Liu, J.G. Tang, Texture evolution and mechanical properties of 6016 aluminum alloys as equal channel angular rolling at different preheat temperatures. Chin. J. Rare Metals 42(06), 586–593 (2018). https://doi.org/10.13373/j.cnki.cjrm.xy17030006

Y.P. Xu, Y.L. Ren, Z.B. Xu, F. Chen, C.Y. Huang, F. Xie, Effect of cold rolling process on r value of 6016 aluminum alloy. Hot Work. Technol. 49(23), 41–44 (2020). https://doi.org/10.14158/j.cnki.1001-3814.20193350

F. Wang, L.C. Zu, D.W. Huang, Y. Zhang, J.S. Chen, X.Y. Zhang, Effect of final rolling temperature on uniformity of mechanical properties of 6061 aluminum alloy plate. Hot Work. Technol. 51(09), 43–46+51 (2021). https://doi.org/10.14158/j.cnki.1001-3814.202124

C.J.T. Mason, R.I. Rodriguez, D.Z. Avery, B.J. Phillips, B.P. Bernarding, M.B. Williams, P.G. Allison, Process-structure-property relations for as-deposited solid-state additively manufactured high-strength aluminum alloy. Addit. Manuf. 40, 101879 (2021). https://doi.org/10.1016/j.addma.2021.101879

J. Oh, H.D. Park, M. Gwak, J. Lee, S. Son, A. Amanov, J.G. Kim, Mechanical property enhancement in gradient structured aluminum alloy by ultrasonic nanocrystalline surface modification. Mater. Sci. Eng. A 812, 141101 (2021). https://doi.org/10.1016/j.msea.2021.141101

Acknowledgements

This work was supported by Special funds for local scientific and technological development under the guidance of the central government (GuiKeZY21195030) and Guangxi Science and Technology Base and Talent Project (GuiKeAD21238010).

Author information

Authors and Affiliations

Contributions

YR and AL designed and performed the experiments, analyzed the data, and prepared the paper. TZ and LW participated to collect the materials related to the experiment. YH and BL designed the experiments and revised the manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rao, Y., Li, A., Zuo, T. et al. Influence of different rolling processes on the microstructures and mechanical properties of 6016 aluminum alloy. Appl. Phys. A 129, 690 (2023). https://doi.org/10.1007/s00339-023-06969-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06969-4