Abstract

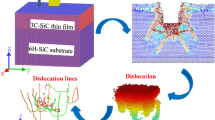

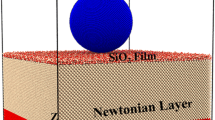

To elucidate the effect of water film on the behavior of single-crystal cubic silicon carbide (SiC) under nano-indentation, molecular dynamics (MD) simulations were employed in this work. Results showed that a pop-in event occurs during nano-indentation, which is jointly controlled by the atomic amorphization and dislocation nucleation. Compared to substrate without any water film, the depth of the incipient pop-in event of the substrate decreases with the thickness of water film, where the larger the water film thickness, the lower the depth. Therefore, it is concluded that the plasticity of the material is improved with the addition of water film. Besides, the number and length of dislocations of the substrate increase with the water film, and the migration of perfect dislocations in the [110] crystal direction of packed {111} plane also become homogenized. As the water film thickness increases, dislocation activities become more prevalent; however, the recovery of deformed crystal structure gets restrained. Owing to the increase of hydrostatic stress, the sub-surface damage of the substrate is exacerbated with the water film. In addition, the surface bulge of the substrate ascends with the water film. Finally, it is observed that the inhomogeneity of the surface bulge distribution is boosted with increasing water film thickness, while the adhesion of amorphous atoms to the diamond indenter is weakened.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

X. Luo, S. Goel, R.L. Reuben, A quantitative assessment of nanometric machinability of major polytypes of single crystal silicon carbide. J. Eur. Ceram. Soc. 32(12), 3423–3434 (2012)

W. Wu, Y. Hu, X. Meng et al., Molecular dynamics simulation of ion-implanted single-crystal 3C-SiC nano-indentation. J. Manuf. Process. 79, 356–368 (2022)

X. Li, G. Zeng, X. Lei, The stability, optical properties and solar-thermal conversion performance of SiC-MWCNTs hybrid nanofluids for the direct absorption solar collector (DASC) application. Sol. Energy Mater. Sol. Cells 206, 110323 (2020)

H. Dai, Y. Hu, W. Wu et al., Molecular dynamics simulation of ultra-precision machining 3C-SiC assisted by ion implantation. J. Manuf. Process. 69, 398–411 (2021)

L. Zhao, W. Hu, Q. Zhang et al., Atomistic origin of brittle-to-ductile transition behavior of polycrystalline 3C–SiC in diamond cutting. Ceram. Int. 47(17), 23895–23904 (2021)

S. Goel, X. Luo, R.L. Reuben, Molecular dynamics simulation model for the quantitative assessment of tool wear during single point diamond turning of cubic silicon carbide. Comput. Mater. Sci. 51(1), 402–408 (2012)

B. Luan, M.O. Robbins, The breakdown of continuum models for mechanical contacts. Nature 435(7044), 929–932 (2005)

N. Vu-Bac, M.A. Bessa, T. Rabczuk et al., A multiscale model for the quasi-static thermo-plastic behavior of highly cross-linked glassy polymers. Macromolecules 48(18), 6713–6723 (2015)

P.R. Budarapu, B. Javvaji, J. Reinoso et al., A three dimensional adaptive multiscale method for crack growth in silicon. Theor. Appl. Fract. Mech. 96, 576–603 (2018)

N. Vu-Bac, P.M.A. Areias, T. Rabczuk, A multiscale multisurface constitutive model for the thermo-plastic behavior of polyethylene. Polymer 105, 327–338 (2016)

N. Vu-Bac, T. Lahmer, Y. Zhang et al., Stochastic predictions of interfacial characteristic of polymeric nanocomposites (PNCs). Compos. B Eng. 59, 80–95 (2014)

W. Wu, Y. Hu, X. Meng et al., Molecular dynamics analysis of the influence of ion implantation parameters on ultra-precision machining of silicon carbide. J. Manuf. Process. 82, 174–191 (2022)

Z. Wu, W. Liu, L. Zhang, Effect of structural anisotropy on the dislocation nucleation and evolution in 6H SiC under nanoindentation. Ceram. Int. 45(11), 14229–14237 (2019)

X. Zhao, R.M. Langford, I.P. Shapiro et al., Onset plastic deformation and cracking behavior of silicon carbide under contact load at room temperature. J. Am. Ceram. Soc. 94(10), 3509–3514 (2011)

R. Devanathan, T.D. De La Rubia, W.J. Weber, Displacement threshold energies in β-SiC. J. Nucl. Mater. 253(1–3), 47–52 (1998)

H. Chen, R.K. Kalia, A. Nakano et al., Multimillion-atom nanoindentation simulation of crystalline silicon carbide: orientation dependence and anisotropic pileup. J. Appl. Phys. 102(6), 63514 (2007)

M. Chen, H. Dai, Molecular dynamics study on grinding mechanism of polycrystalline silicon carbide. Diam. Relat. Mater. 130, 109541 (2022)

P.R. Budarapu, B. Javvaji, V.K. Sutrakar et al., Crack propagation in graphene. J. Appl. Phys. 118(6), 064307 (2015)

P.R. Budarapu, B. Javvaji, V.K. Sutrakar et al., Lattice orientation and crack size effect on the mechanical properties of graphene. Int. J. Fract. 203(1–2), 81–98 (2017)

I. Szlufarska, R.K. Kalia, A. Nakano et al., Nanoindentation-induced amorphization in silicon carbide. Appl. Phys. Lett. 85(3), 378–380 (2004)

L. Zhao, M. Alam, J. Zhang et al., Amorphization-governed elasto-plastic deformation under nanoindentation in cubic (3C) silicon carbide. Ceram. Int. 46(8), 12470–12479 (2020)

C. Pan, L. Zhang, W. Jiang et al., Grain size dependence of hardness in nanocrystalline silicon carbide. J. Eur. Ceram. Soc. 40(13), 4396–4402 (2020)

M. Mishra, I. Szlufarska, Possibility of high-pressure transformation during nanoindentation of SiC. Acta Mater. 57(20), 6156–6165 (2009)

S. Sun, X. Peng, H. Xiang et al., Molecular dynamics simulation in single crystal 3C-SiC under nanoindentation: formation of prismatic loops. Ceram. Int. 43(18), 16313–16318 (2017)

J. Shi, J. Chen, L. Fang et al., Atomistic scale nanoscratching behavior of monocrystalline Cu influenced by water film in CMP process. Appl. Surf. Sci. 435, 983–992 (2018)

Y. Zhou, Y. Huang, J. Li et al., Effect of water film on the nano-scratching process of 4H-SiC under the constant load. Tribol. Int. 175, 107802 (2022)

C.Y. Tang, L.C. Zhang, A molecular dynamics analysis of the mechanical effect of water on the deformation of silicon monocrystals subjected to nano-indentation. Nanotechnology 16(1), 15–20 (2005)

A.B. Mann, J.B. Pethica, Nanoindentation studies in a liquid environment. Langmuir 12(19), 4583–4586 (1996)

J. Shi, Y. Zhang, K. Sun et al., Effect of water film on the plastic deformation of monocrystalline copper. RSC Adv. 6(99), 96824–96831 (2016)

J. Shi, J. Chen, K. Sun et al., Water film facilitating plastic deformation of Cu thin film under different nanoindentation modes: a molecular dynamics study. Mater. Chem. Phys. 198, 177–185 (2017)

E. Brinksmeier, J.C. Aurich, E. Govekar et al., Advances in modeling and simulation of grinding processes. CIRP Ann. 55(2), 667–696 (2006)

X. Liu, Y. Liu, L. Li et al., Optimization of the micro-textures on the cutting tool based on the penetration of the lubricant in the micro-textures. Int. J. Adv. Manuf. Technol. 104(5–8), 3173–3180 (2019)

S. Goel, X. Luo, P. Comley et al., Brittle–ductile transition during diamond turning of single crystal silicon carbide. Int. J. Mach. Tools Manuf. 65, 15–21 (2013)

A.P. Thompson, H.M. Aktulga, R. Berger et al., LAMMPS—a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 271, 108171 (2022)

S. Goel, X. Luo, A. Agrawal et al., Diamond machining of silicon: a review of advances in molecular dynamics simulation. Int. J. Mach. Tools Manuf. 88, 131–164 (2015)

H.W. Horn, W.C. Swope, J.W. Pitera et al., Development of an improved four-site water model for biomolecular simulations: TIP4P-Ew. J. Chem. Phys. 120(20), 9665–9678 (2004)

P. Vashishta, R.K. Kalia, A. Nakano et al., Interaction potential for silicon carbide: a molecular dynamics study of elastic constants and vibrational density of states for crystalline and amorphous silicon carbide. J. Appl. Phys. 101(10), 103515 (2007)

P. Erhart, K. Albe, Analytical potential for atomistic simulations of silicon, carbon, and silicon carbide. Phys. Rev. B 71(3), 35211 (2005)

J. Ren, J. Zhao, Z. Dong et al., Molecular dynamics study on the mechanism of AFM-based nanoscratching process with water-layer lubrication. Appl. Surf. Sci. 346, 84–98 (2015)

A. Stukowski, Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 18(1), 2154–2162 (2010)

K. Xue, L. Niu, A crossover in the mechanical response of silicon carbide due to the accumulation of chemical disorder. J. Appl. Phys. 107(8), 083517 (2010)

A. Nawaz, B. Islam, W. Mao et al., Nanoscale elastic-plastic deformation and mechanical properties of 3C-SiC thin film using nanoindentation. Int. J. Appl. Ceram. Technol. 16(2), 706–717 (2018)

S. Goel, W. Bin Rashid, X. Luo et al., A theoretical assessment of surface defect machining and hot machining of nanocrystalline silicon carbide. J Manuf Sci Eng 136(2), 021015 (2014)

Z. Ou, W. Wu, H. Dai, Quantitative analysis of grinding performance of cubic silicon carbide surface texture lubricated with water film. Tribol. Int. 180, 108267 (2023)

X. Meng, W. Wu, B. Liao et al., Atomic simulation of textured silicon carbide surface ultra-precision polishing. Ceram. Int. 48(12), 17034–17045 (2022)

S. Goel, The current understanding on the diamond machining of silicon carbide. J. Phys. D Appl. Phys. 47(24), 1–36 (2014)

S.Z. Chavoshi, X. Luo, Molecular dynamics simulation study of deformation mechanisms in 3C–SiC during nanometric cutting at elevated temperatures. Mater. Sci. Eng. A 654, 400–417 (2016)

H. Dai, H. Yue, Y. Hu et al., The removal mechanism of monocrystalline Si in the process of double diamond abrasive polishing by molecular dynamics simulation. Tribol. Lett. 69(2), 66 (2021)

Acknowledgements

The authors would like to appreciate the National Natural Science Foundation of China (12162008, 52105178), Natural Science Foundation of Hunan Province (2022JJ40056), and Technology Foundation of Guizhou Province of China [JC(2020)1Y229].

Author information

Authors and Affiliations

Contributions

ZO: completion of article revisions, investigation, data curation, writing—original draft. WW: conceptualization, investigation, data curation, writing—original draft. HD: conceptualization, investigation, data curation, formal analysis, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethical approval

Ethical approval was obtained from the College of Mechanical Engineering of Guizhou University.

Consent to participate

Not applicable.

Consent to publish

All authors have seen the manuscript and approved to submit to your journal, and we would greatly appreciate for your attention and consideration.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ou, Z., Wu, W. & Dai, H. Molecular dynamics simulation-based study of single-crystal 3C-SiC nano-indentation with water film. Appl. Phys. A 129, 658 (2023). https://doi.org/10.1007/s00339-023-06929-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06929-y