Abstract

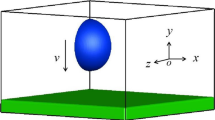

Modeling drop impact in 3D in thermal spraying conditions poses a great challenge, since it requires first of all an accurate interface tracking model and an efficient numerical scheme to solve the governing equations. This paper thus put forward an integrated model, in the framework of the conservative level set equation, to simulate drop impact in real thermal spraying conditions. The model couples the conservative level set equation with the Navier–Stokes equation and is discretized using the finite difference method on a half-staggered grid. The model was validated against experimental data, showing reasonable agreement. Then it was applied to real impact in thermal spraying conditions. Nickel drop impact with solidification was simulated first. Subsequently, effects of contact angle, thermal contact resistance, and substrate materials, were examined. It shows that lower contact angle does not lead to larger contact area, since solidification commences faster around the contact line, thereby pinning its movement, and that thermal contact resistance exerts a huge impact on final splat shape. The smaller the contact resistance, the more violent the splash.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

A. Meghwal, A. Anupam, B.S. Murty, C.C. Berndt, R.S. Kottada, A.S.M. Ang, Thermal spray high-entropy alloy coatings: a review. J. Therm. Spray Technol. 29(5), 857–893 (2020). https://doi.org/10.1007/s11666-020-01047-0

D. Tejero-Martin, M. Rezvani Rad, A. McDonald, T. Hussain, Beyond traditional coatings: a review on thermal-sprayed functional and smart coatings. J. Therm. Spray Technol. 28(4), 598–644 (2019). https://doi.org/10.1007/s11666-019-00857-1

B. Huang, C. Zhang, G. Zhang, H. Liao, Wear and corrosion resistant performance of thermal-sprayed Fe-based amorphous coatings: a review. Surf. Coat. Technol. 377, 124896 (2019). https://doi.org/10.1016/j.surfcoat.2019.124896

S. Morelli, V. Testa, G. Bolelli, O. Ligabue, E. Molinari, N. Antolotti, L. Lusvarghi, CMAS corrosion of YSZ thermal barrier coatings obtained by different thermal spray processes. J. Eur. Ceram. Soc. 40(12), 4084–4100 (2020). https://doi.org/10.1016/j.jeurceramsoc.2020.04.058

A. Fardan, R. Ahmed, Modeling the evolution of residual stresses in thermally sprayed YSZ coating on stainless steel substrate. J. Therm. Spray Technol. 28(4), 717–736 (2019). https://doi.org/10.1007/s11666-019-00856-2

V.V. Satyavathi Yedida, H. Vasudev, A review on the development of thermal barrier coatings by using thermal spray techniques. Mater. Today 50, 1458–1464 (2022). https://doi.org/10.1016/j.matpr.2021.09.018

A. Silvello, P. Cavaliere, A. Rizzo, D. Valerini, S. Dosta Parras, I. Garcia Cano, Fatigue bending behavior of cold-sprayed Nickel-based superalloy coatings. J. Therm. Spray Technol. 28(5), 930–938 (2019). https://doi.org/10.1007/s11666-019-00865-1

P. Shi, W. Wang, S. Wan, Q. Gao, H. Sun, X. Feng, G. Yi, E. Xie, Q. Wang, Tribological performance and high temperature oxidation behaviour of thermal sprayed Ni- and NiCrAlY-based composite coatings. Surf. Coat. Technol. 405, 126615 (2021). https://doi.org/10.1016/j.surfcoat.2020.126615

N.K. Singh, A.S.M. Ang, D.K. Mahajan, H. Singh, Cavitation erosion resistant nickel-based cermet coatings for monel K-500. Tribol. Int. 159, 106954 (2021). https://doi.org/10.1016/j.triboint.2021.106954

C.U. Hardwicke, Y.-C. Lau, Advances in thermal spray coatings for gas turbines and energy generation: a review. J. Therm. Spray Technol. 22(5), 564–576 (2013). https://doi.org/10.1007/s11666-013-9904-0

R. Scardovelli, S. Zaleski, Direct numerical simulation of free-surface and interfacial flow. Annu. Rev. Fluid Mech. 31(1), 567–603 (1999). https://doi.org/10.1146/annurev.fluid.31.1.567

L. Xia, F. Chen, T. Liu, D. Zhang, Y. Tian, D. Zhang, Phase-field simulations of droplet impact on superhydrophobic surfaces. Int. J. Mech. Sci. 240, 107957 (2023). https://doi.org/10.1016/j.ijmecsci.2022.107957

A. Hu, D. Liu, 3D simulation of micro droplet impact on the structured superhydrophobic surface. Int. J. Multiph. Flow 147, 103887 (2022). https://doi.org/10.1016/j.ijmultiphaseflow.2021.103887

D. Hernández-Cid, V.H. Pérez-González, R.C. Gallo-Villanueva, J. González-Valdez, M.A. Mata-Gómez, Modeling droplet formation in microfluidic flow-focusing devices using the two-phases level set method. Mater. Today 48, 30–40 (2022). https://doi.org/10.1016/j.matpr.2020.09.417

S. Osher, R.P. Fedkiw, Level set methods: an overview and some recent results. J. Comput. Phys. 169(2), 463–502 (2001). https://doi.org/10.1006/jcph.2000.6636

E. Olsson, G. Kreiss, A conservative level set method for two phase flow. J. Comput. Phys. 210(1), 225–246 (2005). https://doi.org/10.1016/j.jcp.2005.04.007

J. Mostaghimi, S. Chandra, R. Ghafouri-Azar, A. Dolatabadi, Modeling thermal spray coating processes: a powerful tool in design and optimization. Surf. Coat. Technol. 163–164, 1–11 (2003). https://doi.org/10.1016/s0257-8972(02)00686-2

C.-W. Kang, J.K. Tan, L. Pan, C.Y. Low, A. Jaffar, Numerical and experimental investigations of splat geometric characteristics during oblique impact of plasma spraying. Appl. Surf. Sci. 257(24), 10363–10372 (2011). https://doi.org/10.1016/j.apsusc.2011.06.081

Flow Science Inc., FLOW-3D® Users Manual V9.4, Santa Fe, NM (2010)

C. Le Bot, S. Vincent, E. Meillot, F. Sarret, J.-P. Caltagirone, L. Bianchi, Numerical simulation of several impacting ceramic droplets with liquid/solid phase change. Surf. Coat. Technol. 268, 272–277 (2015). https://doi.org/10.1016/j.surfcoat.2014.10.047

J. Lee, K.K. Subedi, G.W. Huang, J. Lee, S.-C. Kong, Numerical investigation of YSZ droplet impact on a heated wall for thermal spray application. J. Therm. Spray Technol. 31(7), 2039–2049 (2022). https://doi.org/10.1007/s11666-022-01437-6

M.J. Nasiri, A. Dolatabadi, C. Moreau, Modeling of liquid detachment and fragmentation during the impact of plasma spray particles on a cold substrate. Int. J. Heat Mass Transf. 189, 122718 (2022). https://doi.org/10.1016/j.ijheatmasstransfer.2022.122718

Y. Zhang, S.A. Matthews, A. Tran, M. Hyland, Effects of interfacial heat transfer, surface tension and contact angle on the formation of plasma-sprayed droplets through simulation study. Surf. Coat. Technol. 307, 807–816 (2016). https://doi.org/10.1016/j.surfcoat.2016.09.066

M. Ashour, N. Valizadeh, T. Rabczuk, Phase-field Navier-Stokes model for vesicle doublets hydrodynamics in incompressible fluid flow. Comput. Methods Appl. Mech. Eng. 412, 116063 (2023). https://doi.org/10.1016/j.cma.2023.116063

P.-H. Chiu, Y.-T. Lin, A conservative phase field method for solving incompressible two-phase flows. J. Comput. Phys. 230(1), 185–204 (2011). https://doi.org/10.1016/j.jcp.2010.09.021

M. Shen, B.Q. Li, Q. Yang, Y. Bai, Y. Wang, S. Zhu, B. Zhao, T. Li, Y. Hu, A modified phase-field three-dimensional model for droplet impact with solidification. Int. J. Multiph. Flow 116, 51–66 (2019). https://doi.org/10.1016/j.ijmultiphaseflow.2019.04.004

H.Z. Yuan, Z. Chen, C. Shu, Y. Wang, X.D. Niu, S. Shu, A free energy-based surface tension force model for simulation of multiphase flows by level-set method. J. Comput. Phys. 345, 404–426 (2017). https://doi.org/10.1016/j.jcp.2017.05.020

D. Jacqmin, Contact-line dynamics of a diffuse fluid interface. J. Fluid Mech. 402, 57–88 (2000). https://doi.org/10.1017/s0022112099006874

H. Ding, P.D.M. Spelt, C. Shu, Diffuse interface model for incompressible two-phase flows with large density ratios. J. Comput. Phys. 226(2), 2078–2095 (2007). https://doi.org/10.1016/j.jcp.2007.06.028

J. Kim, A continuous surface tension force formulation for diffuse-interface models. J. Comput. Phys. 204(2), 784–804 (2005). https://doi.org/10.1016/j.jcp.2004.10.032

M. Shen, B.Q. Li, Bubble rising and interaction in ternary fluid flow: a phase field study. RSC Adv. 13(6), 3561–3574 (2023). https://doi.org/10.1039/d2ra06144a

Y. Sui, H. Ding, P.D.M. Spelt, Numerical simulations of flows with moving contact lines. Annu. Rev. Fluid Mech. 46(1), 97–119 (2014). https://doi.org/10.1146/annurev-fluid-010313-141338

S. Mirjalili, C.B. Ivey, A. Mani, A conservative diffuse interface method for two-phase flows with provable boundedness properties. J. Comput. Phys. 401, 109006 (2020). https://doi.org/10.1016/j.jcp.2019.109006

C.R. Swaminathan, V.R. Voller, A general enthalpy method for modeling solidification processes. Metall. Trans. B 23(5), 651–664 (1992). https://doi.org/10.1007/bf02649725

Y. Zhang, S. Matthews, M. Hyland, Modelling the spreading behaviour of plasma-sprayed nickel droplets under different impact conditions. J. Phys. D 50(27), 275601 (2017). https://doi.org/10.1088/1361-6463/aa760e

M. Wörner, N. Samkhaniani, X. Cai, Y. Wu, A. Majumdar, H. Marschall, B. Frohnapfel, O. Deutschmann, Spreading and rebound dynamics of sub-millimeter urea-water-solution droplets impinging on substrates of varying wettability. Appl. Math. Model. 95, 53–73 (2021). https://doi.org/10.1016/j.apm.2021.01.038

N. Valizadeh, T. Rabczuk, Isogeometric analysis for phase-field models of geometric PDEs and high-order PDEs on stationary and evolving surfaces. Comput. Methods Appl. Mech. Eng. 351, 599–642 (2019). https://doi.org/10.1016/j.cma.2019.03.043

J. Qu, Y. Yang, S. Yang, D. Hu, H. Qiu, Droplet impingement on nano-textured superhydrophobic surface: experimental and numerical study. Appl. Surf. Sci. 491, 160–170 (2019). https://doi.org/10.1016/j.apsusc.2019.06.104

M. Pasandideh-Fard, V. Pershin, S. Chandra, J. Mostaghimi, Splat shapes in a thermal spray coating process: simulations and experiments. J. Therm. Spray Technol. 11(2), 206–217 (2002). https://doi.org/10.1361/105996302770348862

A.L. Yarin, Drop impact dynamics: Splashing, spreading, receding, bouncing…. Annu. Rev. Fluid Mech. 38(1), 159–192 (2006). https://doi.org/10.1146/annurev.fluid.38.050304.092144

C.D. Stow, M.G. Hadfield, An experimental investigation of fluid flow resulting from the impact of a water drop with an unyielding dry surface. Proc. R. Soc. Lond. A 373(1755), 419–441 (1981). https://doi.org/10.1098/rspa.1981.0002

M. Bussmann, S. Chandra, J. Mostaghimi, Modeling the splash of a droplet impacting a solid surface. Phys. Fluids 12(12), 3121–3132 (2000). https://doi.org/10.1063/1.1321258

Y. Yonemoto, M. Yamashita, K. Tashiro, T. Kunugi, Estimating the number of fingers and size of ejected droplets in droplet impingement processes on solid substrates. Colloid Interface Sci. Commun. 50, 100651 (2022). https://doi.org/10.1016/j.colcom.2022.100651

Acknowledgements

This research is supported by the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (Grant No. 21KJB460034).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None declared.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shen, M., Li, B.Q. A 3D numerical study on impact-freezing of Nickel drops in thermal spraying conditions. Appl. Phys. A 129, 509 (2023). https://doi.org/10.1007/s00339-023-06781-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06781-0