Abstract

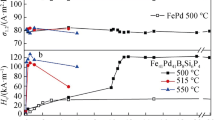

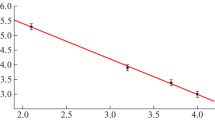

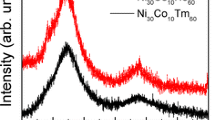

The crystallization process, microstructure, thermal stability, and magnetic properties of Fe86Cr6P6C2 amorphous ribbons were studied by X-ray diffraction, scanning electron microscopy coupled with energy dispersive X-ray spectroscopy, differential scanning calorimetry, and vibration sample magnetometry. The crystallization process occurs in three stages where nanocrystalline α-Fe solid solution, Fe3P phosphide, θ-Fe3C and ε-Fe3C carbides are formed. The crystallite size increases with increasing annealing temperature and remains at the nanometer scale (20–88 nm). The microstructure of the annealed ribbons consists of lamella, fine platelets, alternate planes of ferrite and cementite, and grains with different shapes and sizes. The activation energies (499, 386, and 369 kJ/mol) are determined by Kissinger method. The melt-spun ribbons exhibit a low coercivity of 16.598 Oe and a high saturation magnetization of 0.635 emu compared to the annealed ones. The saturation magnetization decreases to a minimum value for the annealed ribbons at 758 K and then increases with increasing the annealing temperature. The Curie temperature increases from 447.4 K for the melt-spun ribbons to 638 K for the fully crystallized ribbons due to the development of the α-Fe phase.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

A. Kupczyk, J. Świerczek, M. Hasiak, K. Prusik, J. Zbroszczyk, P. Gębara, Microstructure and some thermomagnetic properties of amorphous Fe-(Co)-Mn-Mo-B alloys. J. Alloys Compd. 735, 253–260 (2018). https://doi.org/10.1016/j.jallcom.2017.10.278

C. Souza, D. Ribeiro, C. Kiminami, Corrosion resistance of Fe-Cr-based amorphous alloys: an overview. J. Non-Cryst. Solids 442, 56 (2016). https://doi.org/10.1016/j.jnoncrysol.2016.04.009

G. Zhang, H. Zhang, S. Yue, A. Wang, A. He, R. Cheng, C.T. Liu, Ultra-low cost and energy-efficient production of FePCSi amorphous alloys with pretreated molten iron from a blast furnace. J. Non-Cryst. Solids 514, 108–115 (2019). https://doi.org/10.1016/j.jnoncrysol.2019.03.045

Y. Fan, S. Zhang, X. Xu, W. Miao, J. Zhang, T. Wang, C. Chen, R. Wei, F. Li, Effect of the substitution of Si for B on thermal stability, magnetic properties and corrosion resistance in novel Fe-rich amorphous soft magnetic alloy. Intermetallics 138, 107306 (2021). https://doi.org/10.1016/j.intermet.2021.107306

A. Wang, C. Zhao, H. Men, A. He, C. Chang, X. Wang, R.W. Li, Fe-based amorphous alloys for wide ribbon production with high Bs and outstanding amorphous forming ability. J. Alloy Compd. (2015). https://doi.org/10.1016/j.jallcom.2015.01.056

T. Bitoh, D. Watanabe, Effect of yttrium addition on glass-forming ability and magnetic properties of Fe–Co–B–Si–Nb bulk metallic glass. Metals 5, 1127–1135 (2015). https://doi.org/10.3390/met5031127

M. Shi, Z. Liu, T. Zhang, Effects of minor Sn addition on the glass formation and properties of Fe- metalloid metallic glasses with high magnetization and high glass forming ability. J. Magn. Mater. 378, 417–423 (2015). https://doi.org/10.1016/j.jmmm.2014.10.144

G.Y. Koga, C. Bolfarini, C.S. Kiminami, A.M. Jorge, W.J. Botta, An overview of thermally sprayed Fe-Cr-Nb-B metallic glass coatings: from the alloy development to the coating’s performance against corrosion and wear. J. Therm Spray Tech. 31(4), 923–955 (2022). https://doi.org/10.1007/s11666-022-01371-7

A. Łukiewska, P. Gębara, Structure, magnetocaloric effect and critical behavior of the Fe60Co12Gd4Mo3B21 amorphous ribbons. Materials 15(1), 34 (2021). https://doi.org/10.3390/ma15010034

L. Pei, X. Zhang, Z. Yuan, Application of Fe-based amorphous alloy in industrial wastewater treatment: a review. J. Renew. Mater. 10(4), 969 (2022). https://doi.org/10.32604/jrm.2022.017617

Y. Takahara, K. Hatade, H. Matsuda, Reversible structural relaxation in Fe78B7Si15 and Fe40Ni40P14B6 amorphous alloys. Trans. Jap. Inst. Metals 29(10), 774–780 (1988). https://doi.org/10.2320/matertrans1960.29.774

T. Egami, Structural relaxation in amorphous alloys-compositional short range ordering. Mater. Res. Bull. 13, 557–562 (1978). https://doi.org/10.1016/0025-5408(78)90178-2

F.C. Li, T. Liu, J.Y. Zhang, S. Shuang, Q. Wang, A.D. Wang, Y. Yang, Amorphous– nanocrystalline alloys: fabrication, properties, and applications. Mat. Today Adv. 4, 100027 (2019). https://doi.org/10.1016/j.mtadv.2019.100027

A. Cotai, S. Miraglia, B. Neamţu, T. Marinca, H. Chicinaş, O. Isnard, I. Chicinaş, A comparative study of nanocrystalline Fe38.5Co38.5 Nb7 P15Cu1 alloys obtained by mechanical alloying and rapid quenching. Arch. Metal. Mater. 67(2), 555–561 (2022). https://doi.org/10.24425/amm.2022.137790

J.A. Moya, S.G. Caramella, C. Berejnoi, Evolution of soft magnetic, mechanical and electrical properties measured simultaneously during annealing of rapidly solidified alloys. J. Magn. Magn. Mat. 476, 248–253 (2019). https://doi.org/10.1016/j.jmmm.2019.01.008

L.L. Pang, A. Inoue, E.N. Zanaeva, F. Wang, A.I. Bazlov, Y. Han, F.L. Kong, S.L. Zhu, R.B. Shull, Nanocrystallization, good soft magnetic properties and ultrahigh mechanical strength for Fe82- 85B1316Si1Cu1 amorphous alloys. J. Alloys Compd. 785, 25–37 (2019). https://doi.org/10.1016/j.jallcom.2019.01.150

P. Gębara, M. Hasiak, Investigation of critical behavior in the vicinity of ferromagnetic to paramagnetic phase transition in the Fe75Mo8Cu1B16 alloy. J. Appl. Phys. 124, 083904 (2018). https://doi.org/10.1063/1.5039509

A. Łukiewska, J. Olszewski, M. Hasiak, P. Gębara, Magnetocaloric effect in amorphous and partially crystallized Fe80Zr7Cr6Nb2Cu1B4 alloy. Acta Phys. Pol A 133(3), 676–679 (2018). https://doi.org/10.12693/APhysPolA.133.676

R. Babilas, A. Radoń, P. Gębara, Structure and magnetic properties of Fe-B-Si-Zr metallic glasses. Acta Phys. Pol A 131(4), 726–728 (2017). https://doi.org/10.12693/APhysPolA.131.726

J. Zhou, J. You, K. Qiu, Advances in Fe-based amorphous/nanocrystalline alloys. J. Appl. Phys. 132(4), 040702 (2022). https://doi.org/10.1063/5.0092662

J. Xu, Y. Yang, Q. Yan, C. Fan, F. Hou, Z. Xie, Effect of microalloying on crystallization behavior, magnetic properties and bending ductility of high Fe content FeSiBCuPC alloys. J. Alloys Compd. 777, 499–505 (2019). https://doi.org/10.1016/j.jallcom.2018.11.029

C. Suryanarayana, A. Inoue, Bulk metallic glasses (CRC Press, 2017). https://doi.org/10.1201/9781315153483

N. Bensebaa, S. Alleg, F.Z. Bentayeb, L. Bessais, J.M. Greneche, Microstructural characterization of Fe–Cr–P–C powder mixture prepared by ball milling. J. Alloys Compd. 388(1), 41–48 (2005). https://doi.org/10.1016/j.jallcom.2004.06.075

B. Huang, C. Zhang, G. Zhang, H. Liao, Wear and corrosion resistant performance of thermal- sprayed Fe-based amorphous coatings: a review. Surf. Coat. Technol. 377(4), 124896 (2019). https://doi.org/10.1016/j.surfcoat.2019.124896

B. Bouzabata, S. Alleg, Products of crystallization of amorphous alloy of Fe77Cr4P8C11 and sequences of precipitation. J. Alloys Compd. 178(1–2), 117–124 (1992). https://doi.org/10.1016/0925-8388(92)90252-5

P. Hua, B. Wang, C. Yu, Y. Han, Q. Sun, Shear-induced amorphization in nanocrystalline NiTi micropillars under large plastic deformation. Acta Mater. 241, 118358 (2022). https://doi.org/10.1016/j.actamat.2022.118358

X. Yu, J. Wang, L. Wang, W. Huang, Fabrication and characterization of CrNbSiTiZr high-entropy alloy films by radio-frequency magnetron sputtering via tuning substrate bias. Surf. Coat. Technol. 412, 127074 (2021). https://doi.org/10.1016/j.surfcoat.2021.127074

M. Nabiałek, Fabrication methods for bulk amorphous alloys, in Alloy Materials and Their Allied Applications. ed. by I. Inamuddin, R. Boddula, M.I. Ahamed, A.M. Asiri (Wiley Online Library, 2020), pp.1–26. https://doi.org/10.1002/9781119654919.ch1

J. Zhao, Q. Gao, H. Wang, F. Shu, H. Zhao, W. He, Z. Yu, Microstructure and mechanical properties of Co-based alloy coatings fabricated by laser cladding and plasma arc spray welding. J. Alloys Compd. 785, 846–854 (2019). https://doi.org/10.1016/j.jallcom.2019.01.056

Q. Yan, Y. Gao, C. Du, Z. Yao, Y. Mo, Ultrasonic-assisted shearing characteristics of Fe-based amorphous alloy strips. J. Mater. Eng. Perf. (2022). https://doi.org/10.1007/s11665-022-06952-9

D.H. Milanez, L.I.L. Faria, D.R. Leiva, C.S. Kiminami, W.J. Botta, Assessing technological developments in amorphous/glassy metallic alloys using patent indicators. J. Alloys Compd. 716, 330–335 (2017). https://doi.org/10.1016/j.jallcom.2017.05.105

N.K. Maroju, X. Jin, Mechanism of chip segmentation in orthogonal cutting of Zr-based bulk metallic glass. J. Manuf. Sci. Eng. 141, 081003 (2019). https://doi.org/10.1115/1.4043837

H.P. Tsui, P.H. Lee, C.C. Yeh, J.C. Hung, Ultrasonic vibration-assisted electrical discharge machining on Fe-based metallic glass by adding conductive powder. Proc. CIRP 95, 425–430 (2020). https://doi.org/10.1016/j.procir.2020.02.275

B. De Guillebon, M. Henry, G. Le Gal, C. Tete, Mechanical and magnetic properties of amorphous FeCrPC ribbons and wires. Mat. Sci. Eng. 98, 539–542 (1988). https://doi.org/10.1016/0025-5416(88)90225-X

J. Wang, Y. Di, Z. Fang, S. Guan, T.J. Zhang, Thermal stability, crystallization and soft magnetic properties of Fe-P-C-based glassy alloys. Non-Cryst. Solids 454, 39–45 (2016). https://doi.org/10.1016/j.jnoncrysol.2016.10.014

G. Le Gal, M. Henry, F. Varret, Effect of elaboration velocity on magnetic properties of melt spun amorphous metal ribbons. Revue Phys. App. 22(8), 729–734 (1987). https://doi.org/10.1051/rphysap:01987002208072900

K. Asami, K. Hashimoto, T. Masumoto, S. Shimodaira, ESCA study of the passive film on an extremely corrosion-resistant amorphous iron alloy. Corr. Sci. 16(12), 909–914 (1976). https://doi.org/10.1016/S0010-938X(76)80010-8

I. Raya, S. Chupradit, M.M. Kadhim, M.Z. Mahmoud, A.T. Jalil, A. Surendar, A.N. Bochvar, Role of compositional changes on thermal, magnetic, and mechanical properties of Fe-PC-based amorphous alloys. Chin. Phys. B 31(1), 016401 (2022). https://doi.org/10.1088/1674-1056/ac3655

T. Shmyreva, J. Knapp, Nano-amorphous coatings for medical instruments. In: Medical Device Materials: Proceeding Materials and Processes for Medical Devices Conference., 103–107 (2004)

J.M. Boucheret, Concrete and mortars reinforced with FIBRAFLEX amorphous metallic fibers. In: Workshop on fiber reinforced cement and concrete. University of Sheffield, Sheffield (2004).

J.M. Boucheret, 18 wet sprayed mortars reinforced with flexible metallic fibres for renovation: basic requirements and full-scale experimentation. Sprayed Concr. Technol. 2, 166 (2002)

M. Bourrous, F. Varret, Activation energy distribution in amorphous Fe-Cr–PC alloy, determined for Tc measurements during structural relaxation. Solid state Comm. 57(8), 713–716 (1986). https://doi.org/10.1016/0038-1098(86)90358-3

L. Lutterotti, MAUD version 2.992, http://maud.radiographema.com/. Accessed 28 Nov 2023

H.M. Rietveld, The Rietveld method. Phys. Scr. 89(9), 098002 (2014). https://doi.org/10.1088/0031-8949/89/9/098002

T. Paul, A. Loganathan, A. Agarwal, S.P. Harimkar, Kinetics of isochronal crystallization in a Fe-based amorphous alloy. J. Alloys Compd. 753, 679–687 (2018). https://doi.org/10.1016/j.jallcom.2018.04.133

Y. Wang, X. Li, L. Yue, G. Yang, Z. Li, Q. Sun, M. Xu, J. Yi, Crystallization sequence of an (Al86Ni9La5)98Si2 amorphous alloy under continuous heating. J. Non-Cryst. Solids 610, 122310 (2023). https://doi.org/10.1016/j.jnoncrysol.2023.122310

P. Wang, M. Wei, Y. Dong, Z. Zhu, J. Liu, J. Pang, J. Zhang, Crystallization evolution behavior of amorphous Fe85.7Si7.9B3.6Cr2C0.8 powder produced by a novel atomization process. J. Non- Cryst. Solids 594, 121824 (2022). https://doi.org/10.1016/j.jnoncrysol.2023.122373

A.H. Cai, G. Zhou, P.W. Li, D.W. Ding, Q. An, G.J. Zhou, H. Mao, Crystallization kinetics of Cu50Zr40Ti10 amorphous powder. Thermochim. Acta 714, 179261 (2022). https://doi.org/10.1016/j.tca.2022.179261

D. Janovszky, M. Sveda, A. Sycheva, F. Kristaly, F. Zámborszky, T. Koziel, P. Bala, G. Czel, G. Kaptay, J. Term. Anal. Calorim. 147, 7141–7157 (2022). https://doi.org/10.1007/s10973-021-11054-0

S. Nagakura, Study of metallic carbides by electron diffraction Part III. Iron carbides. J. Phys. Soc. Jpn. 14, 186–195 (1959). https://doi.org/10.1143/JPSJ.14.186

P. Rezaei-Shahreza, A. Seifoddini, S. Hasani, Thermal stability and crystallization process in a Fe-based bulk amorphous alloy: the kinetic analysis. J. Non-Cryst. Solids 471, 286–294 (2017). https://doi.org/10.1016/j.jnoncrysol.2017.05.044

H. Göhring, A. Leineweber, E.J. Mittemeijer, A thermodynamic model for non-stoichiometric cementite; the Fe–C phase diagram. Calphad 52, 38–46 (2016). https://doi.org/10.1016/j.calphad.2015.10.014

H.K.D.H. Bhadeshia, Cementite. Int. Mat. Rev. 65–1, 1–27 (2020). https://doi.org/10.1080/09506608.2018.1560984

H.E. Kissinger, Variation of peak temperature with heating rate in differential thermal analysis. J. Res. Natl. Bur. Stand. 57, 217–221 (1956). https://doi.org/10.1021/ac60131a045

B. Bouzabata, S. Alleg, Kinetics of crystallization of the amorphous alloy Fe77Cr4P8C11. Mat. Chem. Phys. 33(1–2), 70–75 (1993). https://doi.org/10.1016/0254-0584(93)90092-Z

F. Sun, T. Gloriant, Primary crystallization process of amorphous Al88Ni6Sm6 alloy investigated by differential scanning calorimetry and by electrical resistivity. J. Alloys Compd. 477, 133–138 (2009). https://doi.org/10.1016/j.jallcom.2008.10.021

S. Alleg, L. Hamza, M. Ibrir, S. Souilah, W. Tebib, N.E. Fenineche, J.M. Greneche, Microstructural, hyperfine and magnetic properties FeSiBCuNb deposits. J. Supercond. Nov Magn 28(4), 2431–2439 (2015). https://doi.org/10.1007/s10948-015-3038-1

T. Gloriant, S. Surinach, M.D. Baró, Stability and crystallization of Fe–Co–Nb–B amorphous alloys. J. Non-Cryst. Solids 333(3), 320–326 (2004). https://doi.org/10.1016/j.jnoncrysol.2003.10.007

A.J.P. Meyer, M.C. Cadeville, Magnetic properties of iron-phosphorus compounds. J. Phys. Soc. Jpn. 17, 223–225 (1962)

M. Acet, H. Herper, P. Entel, E.F. Wassermann, The phase stability of ε-Fe alloys. J. Phys. IV 11(PR8), 229–234 (2001). https://doi.org/10.1051/jp4:2001839

A. Tsuzuki, S. Sago, S.I. Hirano, High-temperature and pressure preparation and properties of iron carbides Fe7C3 and Fe3C. J. Mater. Sci. 19, 2513–2518 (1984). https://doi.org/10.1007/BF00550805

I.G. Wood, L. Vocadlo, K.S. Knight, D.P. Dobson, W.G. Marshall, G.D. Price, J. Brodholt, Thermal expansion and crystal structure of cementite, Fe3C, between 4 and 600 K determined by time-of-flight neutron powder diffraction. J. Appl. Cryst. 37, 82–90 (2004). https://doi.org/10.1107/S0021889803024695

Y. Yin, K. Zhai, B. Zhang, S. Zhai, Electrical resistivity of iron phosphides at high- pressure and high-temperature conditions with implications for lunar core’s thermal conductivity. J. Geophys. Res. Solid Earth 124(6), 5544–5556 (2019). https://doi.org/10.1029/2018JB017157

E. Fruchart, A.M. Triquet, R. Fruchart, Magnetic studies of borophosphides of iron, Fe3BxP1–x ε and ε1: Notes on the metal bonds of the metal transitive-metalloid in these compounds. Ann. Chim. (Paris) 9(7–8), 323–332 (1964)

Acknowledgements

Special mention to the late Prof. M. Zergoug from the Industrial Techniques Research Center. We would like to thank Mr Foued Khammaci from LM2S Laboratory for the XRD and VSM measurements. L. Abadlia would like to thank Prof. J.-G. Gasser from the University of Lorraine (France) for his constant help.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abadlia, L., Daoudi, M.I. & Alleg, S. Crystallization process, microstructure, thermal behavior, and magnetic properties of melt-spun Fe86Cr6P6C2 ribbons. Appl. Phys. A 129, 487 (2023). https://doi.org/10.1007/s00339-023-06745-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06745-4