Abstract

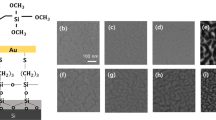

Herein, stacked nanosheets of Au (50 nm) and MgSe (100 nm) are fabricated by the thermal evaporation technique and welded by pulsed lasers of wavelengths of 1064 nm within few seconds. Au/MgSe (AMA) and welded Au/MgSe (PLW) interfaces are coated with another Au point contact and employed as microwave resonators. It is observed that both AMA and PLW devices are of amorphous structure. The laser welding technique resulted in formation clusters composed of very dense grains of Mg1.37AuSe1.18 and other clusters composed of Mg1.16Se. In addition, the impedance spectroscopy measurements on these nano-thick devices have shown their novel ability to perform as negative capacitance sources and as band-stop filters. The pulsed laser welding of these microwave resonators increased their ac conductivities by increasing the hopping sites in the devices. The density of localized states near the Fermi level is increased by ~ 21% and the scattering time constant between hopping sites is shortened via laser welding. As microwave resonators, the pulsed laser welding process shifted the notch frequency from 1.0 to 2.16 GHz, improved the negativity of the capacitance, increased the return loss values and lowered the voltage standing wave ratios to 1.0. The features of the AMA microwave resonators before and after the pulsed laser welding nominate them for use as band-stop filters and as negative capacitance sources.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

E.H. Penilla, L.F. Devia-Cruz, A.T. Wieg, P. Martinez-Torres, N. Cuando-Espitia, P. Sellappan, Y. Kodera, G. Aguilar, J.E. Garay, Science 365, 803–808 (2019). https://doi.org/10.1126/science.aaw6699

H. Naffakh-Moosavy, A. Rasouli, J. Weld. Sci. Technol. Iran 7, 89–101 (2022). http://jwsti.iut.ac.ir/article-1-386-en.html

N.M. Alkhamisi, H.K. Khanfar, A.F. Qasrawi, Physica B: Condens. Matter 649, 414512 (2023). https://doi.org/10.1016/j.physb.2022.414512

S.H. Um, S.W. Hwang, C.P. Grigoropoulos, H. Jeon, S.H. Ko, Appl. Phys. Rev. 9, 041302 (2022). https://doi.org/10.1063/5.0101634

N. Wang, S.I. Rokhlin, D.F. Farson, J. Nanopart. Res. 13, 4491–4509 (2011). https://doi.org/10.1007/s11051-011-0402-3

R.A. Almotiri, A.F. Qasrawi, S.E. Al Garni, J. Electron. Mater. 52, 394–401 (2023). https://doi.org/10.1007/s11664-022-09999-5

R.A. Almotiri, A.F. Qasrawi, S.E. Algarni, Phys. Scr. 97, 125811 (2022). https://doi.org/10.1088/1402-4896/ac9be8

S.E. Algarni, A.F. Qasrawi, N.M. Khusayfan, Cryst. Res. Technol. (2022). https://doi.org/10.1002/crat.202200185

M.P. Wells, R. Bower, R. Kilmurray, B. Zou, A.P. Mihai, G. Gobalakrichenane, NMc.N. Alford, R.F.M. Oulton, L.F. Cohen, S.A. Maier, A.V. Zayats, P.K. Petrov, Opt. Express 26, 15726–15744 (2018). https://doi.org/10.1364/OE.26.015726

M.M. Alkhamisi, H.K. Khanfar, A.F. Qasrawi, S.E. Algarni, Appl. Phys. A 128, 1–10 (2022). https://doi.org/10.1007/s00339-022-06174-9

Z. Lu, Y. Wang, X. Ruan, J. Appl. Phys. 123, 074302 (2018). https://doi.org/10.1063/1.5014987

R. Muthaiah, J. Garg (2021), Preprint at arXiv:2101.12647. https://doi.org/10.48550/arXiv.2101.12647

M.V. Sukhanov, A.D. Plekhovich, T.V. Kotereva, A.M. Gibin, A.M. Potapov, A.M. Kut’in, M.F. Dokl, Chemistry 466, 11–14 (2016). https://doi.org/10.1134/S0012500816010079

Y. Meng, Y. Ma, S. Chen, Y. Han, S. Chen, J. Huang, J. Yang, J. Mater. Process. Technol. 291, 117038 (2021). https://doi.org/10.1016/j.jmatprotec.2020.117038

G.M. Kim, A. Wutzler, H.J. Radusch, G.H. Michler, P. Simon, R.A. Sperling, W.J. Parak, Chem. Mater. 17, 4949–4957 (2005). https://doi.org/10.1021/cm0508120

D. Chen, M. Luo, S. Ning, J. Lan, W. Peng, Y.R. Lu, T.S. Chan, Y. Tan, Small 18, 2104043 (2022). https://doi.org/10.1002/smll.202104043

Y. Uetake, S. Mouri, S. Haesuwannakij, K. Okumura, H. Sakurai, Nanoscale Adv. 3, 1496–1501 (2021). https://doi.org/10.1039/D0NA00951B

G. Sun, Y. Li, X. Zhao, Y. Mi, L. Wang, Am. J. Anal. Chem. 7, 34–42 (2016). https://doi.org/10.4236/ajac.2016.71004

K. Yang, J. Xiao, Z. Ren, Z. Wei, J.W. Luo, S.H. Wei, H.X. Deng, J. Phys. Chem. Lett. 12, 7832–7839 (2021). https://doi.org/10.1021/acs.jpclett.1c01783

J. Wang, J. Qiao, K. Xu, J. Chen, Y. Zhao, B. Qiu, Z. Lin, W. Ji, Y. Chai, Sci. Bull. 65, 1451–1459 (2020). https://doi.org/10.1016/j.scib.2020.05.008

A.F. Qasrawi, H.M. Zyoud, Mater. Res. (2020). https://doi.org/10.1590/1980-5373-MR-2020-0064

Z.N. Kayani, H. Nazli, S. Kousar, S. Riaz, S. Naseem, Ceram. Int. 46, 14605–14612 (2020). https://doi.org/10.1016/j.ceramint.2020.02.261

A. Qasrawi, M. Taleb, Mater. Sci. Pol. 38, 174–180 (2020). https://doi.org/10.2478/msp-2020-0009

A. Ghosh, Phys. Rev. B 41, 1479 (1990). https://doi.org/10.1103/PhysRevB.41.1479

A.A.A. Darwish, M.M. El-Nahass, A.E. Bekheet, J. Alloys Compd. 586, 142–147 (2014). https://doi.org/10.1016/j.jallcom.2013.10.054

C. Latouche, Y.R. Lin, Y. Tobon, E. Furet, J.Y. Saillard, C.W. Liu, A. Boucekkine, Phys. Chem. Chem. Phys. 16, 25840–25845 (2014). https://doi.org/10.1039/C4CP03990D

L.F. Machogo, R.K. Sithole, N. Phao, T. Kolokoto, S.S. Gqoba, M. Mlambo, M.J. Moloto, P.M. Shumbula, P.S. Mdluli, N. Moloto, Mater. Sci. Eng. B 263, 114878 (2021). https://doi.org/10.1016/j.mseb.2020.114878

G. Palyanova, T. Beliaeva, K. Kokh, Y. Seryotkin, T. Moroz, N. Tolstykh, J. Raman Spectrosc. 53, 1012–1022 (2022). https://doi.org/10.1002/jrs.6327

Z. Zhao, T. Yu, P. Si, K. Zhang, W. Lyu, Inf. MIDEM 50, 169–178 (2020). https://doi.org/10.33180/InfMIDEM2020.302

S. Shreya, N. Kumar, S. Anand, I. Amin, J. Electron. Mater. 49, 2349–2357 (2020). https://doi.org/10.1007/s11664-020-07969-3

Z. C. J. Yuan, The Applicability of Ferroelectrics for Analog and Digital Transistor Applications. Doctoral dissertations, University of Alberta, 2022

A.F. Qasrawi, Optik 265, 169529 (2022). https://doi.org/10.1016/j.ijleo.2022.169529

N.M. Khusayfan, A.F. Qasrawi, H.K. Khanfar, Mater. Res. Express 5, 026303 (2018). https://doi.org/10.1088/2053-1591/aaadda

H. Jin, J. Li, L. Wan, Y. Dai, Y. Wei, H. Guo, 2D Mater. 4, 025116 (2017). https://doi.org/10.1088/2053-1583/aa75eb

D.M. Pozar, Microwave engineering (Wiley, New York, 2011)

A. Pant, M. Singh, M.S. Parihar, AEU-Int. J. Electron. Commun. 131, 153638 (2021). https://doi.org/10.1016/j.aeue.2021.153638

L.H.K. Alfhaid, A.F. Qasrawi, Opt. Quant. Electron. 54, 1–11 (2022). https://doi.org/10.1007/s11082-022-03760-2

Acknowledgements

The authors gratefully acknowledge the technical and financial support provided by the Ministry of Education and King Abdulaziz University, DSR, Jeddah, Saudi Arabia.

Funding

This research work was funded by Institutional Fund Projects under grant no. IFPIP:331-665-1443. The authors gratefully acknowledge the technical and financial support provided by the Ministry of Education and King Abdulaziz University, DSR, Jeddah, Saudi Arabia.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Almotiri, R.A., Qasrawi, A.F. & Agha, B.S. Enhancement of the electrical properties of Au/MgSe/Au microwave resonators via pulsed laser welding of MgSe and Au nanosheets. Appl. Phys. A 129, 289 (2023). https://doi.org/10.1007/s00339-023-06583-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06583-4