Abstract

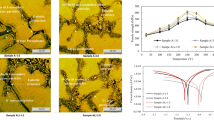

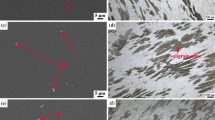

The precipitation and intergranular corrosion (IGC) behavior of Al–1.0Mg–0.6Si–Cu (wt.%) alloys with the addition of Cu ranged from 0.3 to 0.6 wt.% were investigated by optical microscope and transmission electron microscopy. The results indicated that the Cu addition significantly improves the hardness of the alloys during under-aging progress by accelerating the precipitation of GP zones. The addition of Cu has changed the composition of precipitation and facilitated the formation of β′′-Mg5Si6 precipitates with high density and fine distribution. When the Cu content is added to 0.6 wt.%, the type of precipitation has changed. In addition to the needle-shaped β′′ phase, a new-plate Q′ phase precipitated during peak-aging conditions. The 0.6 wt.% Cu alloy shows superior strength with tensile yield strength of 328 MPa, ultimate tensile strength of 368 MPa, and elongation of 16.0%. However, the IGC resistance decreased with the Cu content increasing from 0.3 to 0.6 wt.%, which mainly resulted from the segregation of Cu elements and the formation of continuous Q′ precipitates at the grain boundaries.

Similar content being viewed by others

Availability of data and material

The data are available from the corresponding author on reasonable request.

References

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. De Smet, A. Haszler, A. Vieregge, Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. 280, 37–49 (2000). https://doi.org/10.1016/s0921-5093(99)00653-x

J. Hirsch, Recent development in aluminium for automotive applications. Trans. Nonferrous Metals Soc. China. 24, 1995–2002 (2014). https://doi.org/10.1016/s1003-6326(14)63305-7

Y. Meng, J.Z. Cui, Z.H. Zhao, Y.B. Zuo, Effect of vanadium on the microstructures and mechanical properties of an Al–Mg–Si–Cu–Cr–Ti alloy of 6XXX series. J. Alloys Compd. 573, 102–111 (2013). https://doi.org/10.1016/j.jallcom.2013.03.239

D.L. Chakrabarti, D.E. Laughlin, Phase relations and precipitation in Al–Mg–Si alloys with Cu additions. Prog. Mater. Sci. 49, 389–410 (2004). https://doi.org/10.1016/S0079-6425(03)00031-8

K. Matsuda, S. Ikeno, Y. Uetani, Metastable phases in an Al-Mg-Si alloy containing copper. Metall. Mater. Trans. A. 32, 1293–1299 (2001). https://doi.org/10.1007/s11661-001-0219-2

C.D. Marioara, S.J. Andersen, T.N. Stene, H. Hasting, J. Walmsley, A.T.J. Van Helvoort, R. Holmestad, The effect of Cu on precipitation in Al-Mg-Si alloys. Philos. Mag. 87, 3385–3413 (2007). https://doi.org/10.1117/12.280898

M.W. Zandbergen, A. Cerezo, G. Smith, Study of precipitation in Al-Mg-Si Alloys by atom probe tomography II. Influ. Cu Addit., Acta Mater. 101, 149–158 (2015). https://doi.org/10.1016/j.actamat.2015.08.018

L.P. Ding, Z.H. Jia, Z.Q. Zhang, E.S. Robert, Q. Liu, G. Yang, The natural aging and precipitation hardening behaviour of Al-Mg-Si-Cu alloys with different Mg/Si ratios and Cu additions. Mater. Sci. Eng. 627, 119–126 (2015). https://doi.org/10.1016/j.msea.2014.12.086

L.P. Ding, Z.H. Jia, Z.Q. Zang, Y.Y. Liu, Y.Y. Weng, Q. Liu, The influence of Cu addition and pre-straining on the natural aging and bake hardening response of Al-Mg-Si alloys. J. Alloys Compd. 688, 362–367 (2016). https://doi.org/10.1016/j.jallcom.2016.07.066

M. Murayama, K. Hono, W.F. Miao, D.E. Laughlin, The effect of Cu additions on the precipitation kinetics in an Al-Mg-Si alloy with excess Si. Metall. Mater. Trans. A. 32, 239–246 (2001). https://doi.org/10.1007/s11661-001-0254-z

J.H. Kim, C.D. Marioara, R. Holmestad, E. Kobayashi, T. Sato, Effects of Cu and Ag additions on age-hardening behavior during multi-step aging in Al-Mg-Si alloys. Mater. Sci. Eng. A. 560, 154–162 (2013). https://doi.org/10.1016/j.msea.2012.09.051

W.F. Miao, D.E. Laughlin, Effects of Cu content and preaging on precipitation characteristics in aluminum alloy 6022. Metall. Mater. Trans. A. 31, 361–371 (2000). https://doi.org/10.1007/s11661-000-0272-2

A.I. Morley, M.W. Zandbergen, A. Cerezo, The effect of pre-ageing and addition of copper on the precipitation behaviour in Al-Mg-Si alloys. Mater. Sci. Forum. 519, 543–548 (2006). https://doi.org/10.4028/www.scientific.net/MSF.519-521.543

M. Jin, J. Li, G.J. Shao, The effects of Cu addition on the microstructure and thermal stability of an Al-Mg-Si alloy. J. Alloys Compd. 437, 146–150 (2007). https://doi.org/10.1016/j.jallcom.2006.07.113

Q. Xiao, H.Q. Liu, D.Q. Yi, D.Y. Yin, Y.Q. Chen, Y. Zhang, B. Wang, Effect of Cu content on precipitation and age-hardening behavior in Al-Mg-Si-xCu alloys. J. Alloys Compd. 695, 1005–1013 (2016). https://doi.org/10.1016/j.jallcom.2016.10.221

M. Torsæter, W. Lefebvre, C.D. Marioara, S.J. Andersen, J.C. Walmsley, R. Holmestad, Study of intergrown L and Q′ precipitates in Al-Mg-Si-Cu alloys. Scr. Mater. 64, 817–820 (2011). https://doi.org/10.1016/j.scriptamat.2011.01.008

S. Hirth, G. Marshall, S. Court, D. Lloyd, Effects of Si on the aging behavior and formability of aluminium alloys based on AA6016. Mater. Sci. Eng. A. 319, 452–456 (2001). https://doi.org/10.1016/S0921-5093(01)00969-8

H. Zhan, J.M.C. Mol, F. Hannour, L. Zhuang, H. Terryn, J.H.W. De Wit, The influence of copper content on intergranular corrosion of model AlMgSi(Cu) alloys. Mater. Corros. 59, 670–675 (2015). https://doi.org/10.1002/maco.200804110

Y. Zou, Q. Liu, Z.H. Jia, Y. Xing, L.P. Ding, X.L. Wang, The intergranular corrosion behavior of 6000-series alloys with different Mg/Si and Cu content. Appl. Surf. Sci. 405, 489–496 (2017). https://doi.org/10.1016/j.apsusc.2017.02.045

M.H. Larsen, J.C. Walmsley, O. Lunder, R.H. Mathiesen, K. Nisancioglu, Intergranular corrosion of copper-containing AA6xxx AlMgSi aluminum alloys. J. Electrochem. Soc. 155, 550–556 (2008). https://doi.org/10.1149/1.2976774

S.K. Kairy, T. Alam, P.A. Rometsch, C.H.J. Davies, R. Banerjee, N. Birbilis, Understanding the origins of intergranular corrosion in copper-containing Al–Mg–Si alloys. Metall. Mater. Trans. A. 47, 985–989 (2016). https://doi.org/10.1007/s11661-015-3296-3

G. Svenningsen, J.E. Lein, A. Bjørgum, J.H. Nordlien, Y. Yu, K. Nisancioglu, Effect of low copper content and heat treatment on intergranular corrosion of model AlMgSi alloys. Corros. Sci. 48, 226–242 (2006). https://doi.org/10.1016/j.corsci.2004.11.025

G. Svenningsen, M.H. Larsen, J.C. Walmsley, J.H. Nordlien, K. Nisancioglu, Effect of artificial aging on intergranular corrosion of extruded AlMgSi alloy with small Cu content. Corros. Sci. 48, 1528–1543 (2006). https://doi.org/10.1016/j.corsci.2005.05.045

C.D. Marioara, A. Lervik, J. Grønvold, O. Lunder, S. Wenner, T. Furu, R. Holmestad, The correlation between intergranular corrosion resistance and copper content in the precipitate microstructure in an AA6005 alloy. Metall. Mater. Trans. A. 49, 5146–5156 (2018). https://doi.org/10.1007/s11661-018-4789-7

S. Kumari, S. Wenner, J.C. Walmsley, Progress in understanding initiation of intergranular corrosion on AA6005 aluminum alloy with low copper content. J. Electrochem. Soc. 166, 3114–3123 (2019). https://doi.org/10.1149/2.0211911jes

J. Holmestad, M. Ervik, C.D. Marioara, Investigation of grain boundaries in an Al-Mg-Si-Cu alloy. Mater. Sci. Forum. 794, 951–956 (2014). https://doi.org/10.4028/www.scientific.net/MSF.794-796.951

Z.X. Wang, H. Li, J.H. Gu, R.G. Song, Z.Q. Zheng, Effect of Cu content on microstructures and properties of Al-Mg-Si-Cu alloys. Chin. J. Nonferrous Met. 22, 3348–3355 (2012)

A. Lervik, S. Wenner, O. Lunder, Grain boundary structures and their correlation with intergranular corrosion in an extruded Al-Mg-Si-Cu alloy. Mater. Charact. 170, 110695 (2020). https://doi.org/10.1016/j.matchar.2020.110695

E. Ghali, R. Winstonevie, Corrosion resistance of aluminum and magnesium alloys under-standing, performance, and testing. Corros. Eng. Sci. Technol. 46, 1–2 (2013). https://doi.org/10.1179/147842211X12948245627839

H.W. King, Quantitative size-factors for metallic solid solutions. J. Mater. Sci. 1, 79–90 (1966). https://doi.org/10.1007/bf00549722

D.Y. Yin, Q. Xiao, Y.Q. Chen, H.Q. Liu, D.Q. Yi, B. Wang, S.P. Pan, Effect of natural aging and pre-straining on the hardening behavior and microstructural response during artificial aging of an Al-Mg-Si-Cu alloy. Mater. Des. 95, 329–339 (2016). https://doi.org/10.1016/j.matdes.2016.01.119

K. Matsuda, D. Teguri, Y. Uetani, T. Sato, S. Ikeno, Cu-segregation at the Q′/α-Al interface in Al-Mg-Si-Cu alloy. Scr. Mater. 47, 833–837 (2002). https://doi.org/10.1016/S1359-6462(02)00325-1

O.R. Myhr, Ø. Grong, S.J. Andersen, Modelling of the age hardening behavior of Al-Mg-Si alloys. Acta mater. 49, 65–75 (2001). https://doi.org/10.1016/S1359-6454(00)00301-3

Acknowledgements

This work was supported by Beijing Natural Science Foundation [Grant No. 2202007], National Natural Science Foundation of China [Grant No. 91860113, Grant No. 51621003], and the Beijing Laboratory of Metallic Materials and Processing for Modern Transportation.

Funding

Natural Science Foundation of Beijing Municipality, 2202007, Zuoren Nie, Innovative Research Group Project of the National Natural Science Foundation of China, 91860113, Zuoren Nie, 51621003, Zuoren Nie.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hou, X., Qi, P., Li, B. et al. Precipitation behavior and mechanical properties of Al–1.0Mg–0.6Si–Cu (wt.%) alloy controlled by Cu content. Appl. Phys. A 129, 281 (2023). https://doi.org/10.1007/s00339-023-06580-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06580-7