Abstract

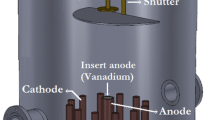

In this work, effects of laser irradiation on several characteristics of vanadium (99.999%) are examined. The square-shaped vanadium samples were irradiated using pulsed Nd:YAG laser (532 nm, 6 ns) at a high fluence (7.46 J/cm2) with 100, 200, 300, and 400 laser shots under vacuum. X-ray diffraction results revealed the preferred orientation of the unirradiated vanadium along (200) plane that remained un-changed upon laser irradiation. The crystallite size varied in the range 30–62 nm and the average diameter of laser-ablated region was decreased with the increase of laser shots. On the contrary, the heat-affected area around the ablated region and the surface roughness progressively increased on increasing the number of laser shots. The morphological features of the laser-irradiated vanadium comprised of cavities, microcones, cracks, grooves dips, bubbles, droplets, ripples, micro-pillars, and wave-like structures. The hardness of the samples (166–184 HV) was decreased with increase of the crystallite size (30–62 nm) and vice versa. The samples irradiated with the laser for 100 and 200 shots exhibited a higher corrosion rate as compared to the un-irradiated sample. However, the corrosion rate was reduced as the number of laser shots were increased to 300 and then 400, demonstrating an improvement in the vanadium corrosion resistance.

Similar content being viewed by others

Availability of data and materials

No additional data available for this article.

References

I. Aramendia, U.F. Gamiz, A.M. San-Vicente, E. Zulueta, J.M. Lopez-Guede, Vanadium redox flow batteries: a review oriented to fluid-dynamic optimization. Energies 14, 176 (2021)

Z.N. Duan, Z.G. Qu, Q. Wang, J.J. Wang, Structural modification of vanadium redox flow battery with high electrochemical corrosion resistance. Appl. Energy 250, 1632–1640 (2019)

R.D. Armstrong, M. Henderson, The anodic dissolution of vanadium in acidic solutions. J. Electroanal. Chem. Interfacial Electrochem. 26, 381–386 (1970)

M.M. El-Rabiee, N.H. Helal, G.M. Abd El-Hafez, W.A. Badawy, Corrosion control of vanadium in aqueous solutions by amino acids. J. Alloys Compd. 459, 466–471 (2008)

M. Maqsood, M. Rafique, M.Z. Butt, N. Afzal, M.U. Tanveer, M. Imran, A. Farooq, Impact of carbon ion implantation on the crystal structure, surface morphology, Vickers hardness and electrochemical corrosion of zirconium. J. Mater. Eng. Perform. 30, 4604–4618 (2021)

M. Rafique, A. Khan, N. Afzal, A. Farooq, M. Imran, Electrochemical corrosion study of helium ions implanted Zircaloy-4 in chloride media. Nucl. Eng. Technol. 53, 927–931 (2021)

N. Afzal, K.M. Deen, R. Ahmad, Z. Niazi, A. Farooq, M. Rafique, Y. Soo-Kim, M.K. Ur-Rahman, Improvement in the pitting resistance of Inconel-600 by nitrogen ions implantation. Prot. Met. Phys. Chem. Surf. 51, 481–485 (2015)

F. Riaz, N. Afzal, M. Rafique, A. Farooq, S.M.H. Ejaz, K.B. Tayyab, R. Ahmad, Improvement in electrochemical corrosion resistance of Mg–Al–Zn alloy. Mater. Res. Express 6, 126452 (2020)

M. Rafique, N. Afzal, R. Ahmad, Impact of 18 MeV He+ ions on the morphological and structural properties of pure Fe. Mater. Res. Express 4, 096504 (2017)

N. Afzal, M. Rafique, W. Javaid, R. Ahmad, A. Farooq, M. Saleem, Z. Khaliq, Influence of carbon ion implantation energy on aluminum carbide precipitation and electrochemical corrosion resistance of aluminum. Nucl. Instrum. Methods Phys. Res. Sect. B 436, 84–91 (2018)

M.H. Akhtar, N. Afzal, M. Rafique, A. Farooq, A. Awais, M.A. Aleem, K.B. Tayyab, Study of hardness and corrosion rate of copper ions irradiated Mg–Al–Zn alloy in ringer lactate solution. Surf. Rev. Lett. 28, 2150054 (2021)

E. McCafferty, Effect of ion implantation on the corrosion behavior of iron, stainless steels, and aluminum: a review. Corrosion 57, 1011–1029 (2001)

A.H. Ramezani, A.H. Sari, A. Shokouhy, The effects of argon ion bombardment on the corrosion resistance of tantalum, International. Nano Lett. 7, 51–57 (2017)

S. Choi, C.S. Kim, K.Y. Jhang, W.S. Shin, Surface characteristics of aluminum 6061–T6 subjected to Nd:YAG pulsed-laser irradiation. J. Mech. Sci. Technol. 26, 2163–2166 (2012)

A. Pereira, A. Cros, P. Delaporte, S. Georgiou, A. Manousaki, W. Marine, M. Sentis, Surface nanostructuring of metals by laser irradiation: effects of pulse duration, wavelength and gas atmosphere. Appl. Phys. A 79, 1433–1437 (2004)

T. Kobayashi, T. Wakabayashi, Y. Takushima, J. Yan, Formation behavior of laser-induced periodic surface structures on stainless tool steel in various media. Precis. Eng. 57, 544–252 (2019)

S.I. Mikolutsky, Yu.V. Khomich, Effect of nanosecond ultraviolet laser radiation on the structure and adhesion properties of metals and alloys. Phys. Met. Metall. 122, 148–153 (2021)

I.V. Borovitskaya, S.N. Korshunov, A.N. Mansurovab, A.B. Mikhailova, V.V. Paramonovaa, G.G. Bondarenko, A.I. Gaidard, E.E. Kazilin, Features of vanadium-surface damage induced by pulsed laser radiation. J. Surf. Investig. X-ray Synchrotron Neutron Tech. 14, 484–489 (2020)

M. Akram, S. Bashir, A. Hayat, K. Mahmood, R. Ahmad, M.K. Ur-Rahman, Effect of laser irradiance on the surface morphology and laser induced plasma parameters of zinc. Laser Part. Beams 32, 119–128 (2014)

L. Haifei, Z. Wang, J. Cai, X. Xu, K. Luo, L. Wu, J. Lu, Effects of laser shock peening on the hot corrosion behaviour of the selective laser melted Ti6Al4V titanium alloy. Corros. Sci. 188, 109558 (2021)

W. Khalfaoui, E. Valerio, J.E. Masse, M. Autric, Excimer laser treatment of ZE41 magnesium alloy for corrosion resistance and microhardness improvement. Opt. Lasers Eng. 48, 926–931 (2010)

T.M. Yue, L.J. Yan, C.P. Cha, C.F. Dong, H.C. Man, G.K.H. Pang, Excimer laser surface treatment of aluminum alloy AA7075 to improve corrosion resistance. Surf. Coat. Technol. 179, 158–164 (2004)

M. Rafique, N. Afzal, R. Mukhtar, I. Younas, S. Bashir, M. Imran, K. Mahmood, A. Farooq, Surface and structural modifications of tungsten by laser irradiation for enhanced electrochemical corrosion resistance. J. Mater. Eng. Perform. 31, 1904–1913 (2022)

J.D. Majumdar, I. Manna, Laser treatment to improve the corrosion resistance of magnesium (Mg) alloys. Corros. Prev. Magnes. Alloys 6, 133–162 (2013)

K.ECh. Vidyasagar, A. Rana, D. Kalyanasundaram, Optimization of laser parameters for improved corrosion resistance of nitinol. Mater. Manuf. Process. 35, 1661–1669 (2020)

U. Trdan, T. Sano, D. Klobcar, Y. Sano, J. Grum, R. Sturm, Improvement of corrosion resistance of AA2024-T3 using femtosecond laser peening without protective and confining medium. Corros. Sci. 143, 46–55 (2018)

M.Z. Butt, A.M. Majeed, M.W. Khaliq, D. Ali, Structural, electrical, and mechanical characterization of Al 5086 alloy irradiated with 248 nm–20 ns KrF excimer laser. J. Alloys Compd. 695, 3069–3082 (2017)

M.Z. Butt, A. Javed, M.W. Khaliq, D. Ali, F. Bashir, Impact of 1064 nm–10 ns pulsed laser on the surface morphology, structure, and hardness of Pd80Ni20 alloy. Int. J. Adv. Manuf. Technol. 90, 1857–1869 (2017)

L.K. Ang, Y.Y. Lau, R.M. Gilgenbach, H.L. Spindler, J.S. Lash, S.D. Kovaleski, Surface instability of multipulse laser ablation on a metallic target. J. Appl. Phys. 83, 4466–4471 (1998)

W. Yoshio, E. Matsubara, K. Shinoda, X-ray diffraction crystallography: introduction, examples and solved problems (Springer Science & Business Media, Berlin, 2011), p.42

J.D. Makinson, J.S. Lee, S.H. Magner, R.J. De Angelis, W.N. Weins, A.S. Hieronymus, X-ray diffraction signatures of defects in nanocrystalline materials. Adv. X-Ray Anal 42, 407–411 (2000)

T. Ungár, Characterization of nanocrystalline materials by X-ray line profile analysis. J. Mater. Sci. 42, 1584–1593 (2007)

G.B. Harris, Quantitative measurement of preferred orientation in rolled uranium bars. Lond. Edinb. Dublin Philos. Mag. J. Sci. 43, 113–123 (1952)

C.S. Barret, T.B. Massalski, Structure of metals (Pergamon Press, Oxford, 1980)

G.K. Williamson, W.H. Hall, X-ray line broadening from filed aluminum and wolfram. Acta Metall. 1, 22–31 (1953)

M.Z. Butt, D. Ali, M. Aftab, F. Bashir, M.S. Pervaiz, M.U. Tanveer, M.W. Khaliq, Nitrogen ions implantation in W-based quad alloy: structure, electrical resistivity, surface roughness and Vickers hardness as a function of ion dose. Met. Mater. Int. 27, 3342–3358 (2021)

N. Afzal, M. Devarajan, K. Ibrahim, Growth of polycrystalline indium aluminum nitride films on Si (111) substrates. Mater. Sci. Semicond. Process. 27, 975-984 (2014)

M.V. Allmen, A. Blatter, Laser-Beam Interactions With Materials: Physical Principles and Applications, vol. 2 (Springer Science & Business Media, Berlin, 2013)

M.S. Brown, C.B. Arnold, Fundamentals of Laser-Material Interaction and Application To Multiscale Surface Modification, in Laser Precision Microfabrication, vol 135 (Springer, Berlin, 2010), pp.91–120

H. Ignacio, R. Fernández, J.M. Gomez-Rodriguez, J.W.S.X. Colchero, J.W.S.X.M. Gómez-Herrero, A.M. Baro, WSXM: a software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instrum. 78, 013705 (2007)

M.W. Khaliq, M.Z. Butt, M. Saleem, Irradiation of zinc single crystal with 500 keV singly-charged carbon ions: surface morphology, structure, hardness, and chemical modifications. Mater. Res. Express 4, 076513 (2017)

M. Aftab, M.Z. Butt, D. Ali, F. Bashir, Z.H. Aftab, Impact of copper doping in NiO thin films on their structure, morphology, and antibacterial activity against Escherichia coli. Ceram. Int. 46, 5037–5049 (2020)

L.L. Taylor, R.E. Scott, J. Qiao, Integrating two-temperature and classical heat accumulation models to predict femtosecond laser processing of silicon. Opt. Mater. Express 8, 648–658 (2018)

V. Craciun, N. Bassim, R.K. Singh, D. Craciun, J. Hermann, C. Boulmer-Leborgne, Laser-induced explosive boiling during nanosecond laser ablation of silicon. Appl. Surf. Sci. 186, 288–292 (2002)

J.C. Miller, R.F. Haglund, Elsevier 30, 647 (1998)

M.Z. Butt, D. Ali, M.U. Tanveer, S.N. Butt, Surface roughness and electrical resistivity of high-purity zinc irradiated with nanosecond visible laser pulses. Appl. Surf. Sci. 305, 466–473 (2014)

R. Hergenröder, A model for the generation of small particles in laser ablation ICP-MS. J. Anal. At. Spectrom. 21, 1016–1026 (2006)

P.T. Mannion, J. Magee, E. Coyne, G.M. O’connor, T.J. Glynn, The effect of damage accumulation behaviour on ablation thresholds and damage morphology in ultrafast laser micro-machining of common metals in air. Appl. Surf. Sci. 233, 275–287 (2004)

S. Sinha, A.K. Singh, Self-assembled microcones generated on solid surface through pulsed laser irradiation. Adv. Mater. Lett. 4, 492–496 (2013)

M.Z. Butt, M.W. Khaliq, A.M. Majeed, D. Ali, Impact of 532 nm 6 ns laser pulses on (104) oriented zinc single crystal: surface morphology, phase transformation, and structure hardness relationship. Mater. Res. Express 3, 096503 (2016)

V.N. Popok, S.V. Prasalovich, M. Samuelsson, E.E. Campbell, Rev. Sci. Instrum. 73, 4287 (2002)

C. Yaddadene, A. Djemaa, Y. Belaroussi, T. Kerdja, N. Gabouze, A. Keffous, L. Guerbous, Optical properties of silicon microcolumn grown by nanosecond pulsed laser irradiation. Opt. Commun. 284, 3308–3310 (2011)

M.Z. Butt, D. Ali, M. Aftab, M.U. Tanveer, Surface topography and structure of laser-treated high-purity zinc. Surf. Topogr. Metrol. Prop. 3, 035002 (2015)

A. Dawood, S. Bashir, M. Akram, A. Hayat, S. Ahmed, M.H. Iqbal, A.H. Kazmi, Effect of nature and pressure of ambient environments on the surface morphology, plasma parameters, hardness, and corrosion resistance of laser-irradiated Mg-alloy. Laser Part. Beams 33, 315–330 (2015)

E.O. Hall, The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. Sect. B 64, 747 (1951)

N.J. Petch, The ductile fracture of polycrystalline α-iron. Philos. Mag. 1, 186–190 (1956)

R.E. Smallman, Modern Physical Metallurgy (Elsevier, New York, 2016)

J. Schiøtz, K.W. Jacobsen, A maximum in the strength of nanocrystalline copper. Science 301, 1357–1359 (2003)

P.B. Johnson, R.W. Christy, Department of Physics and Astronomy, Dartmouth College, Hanover, Hampshire 9 (1974)

M. Rafique, N. Afzal, A. Farooq, R. Ahmad, Effects of carbon ions irradiation on the electrochemical response of AISI 304 stainless steel. Mater. Res. Express 5(10), 106501 (2018)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Iftikhar, R., Rafique, M., Butt, M.Z. et al. Structural, morphological, mechanical and electrochemical properties of 532 nm Nd:YAG laser-irradiated vanadium at high fluence. Appl. Phys. A 129, 269 (2023). https://doi.org/10.1007/s00339-023-06555-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06555-8