Abstract

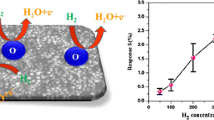

This paper compares two TiO2 thick film gas sensors to the hydrogen at elevated operating temperatures. The first gas sensor was prepared by applying nitrogen treatment at 200 °C for 2 h to the TiO2 powder before the TiO2 paste was prepared. The second gas sensor was prepared using TiO2 powder without purification to make the TiO2 paste. Both TiO2 pastes were prepared by mixing the sensing material with an organic binder. Both pastes were deposited on an alumina substrate using a screen-printing technique and annealed at 500 °C for 30 min under ambient air. FESEM and XRD characterizations were carried out to investigate the morphology and elemental composition. The results revealed that the TiO2 thick film with nitrogen treatment produced slightly higher crystallinity and smaller crystallite sizes for the anatase and rutile phases than the TiO2 thick film without nitrogen treatment. In terms of resistivity, the WTN gas sensor produced lower resistivity than the WON gas sensor for operating temperatures below 200 °C. The results were found that the WON gas sensor had higher sensitivity than the WTN gas sensor to various concentrations of hydrogen at the operating temperature of 150 °C, 200 °C, and 250 °C. Both gas sensors also produced similar optimum operating temperatures, which occurred at 200 °C. The sensitivity of the WON gas sensor was approximately 6.30, 8.39, 12.70, 15.92, and 19.87 optimum operating temperatures to 100 ppm, 300 ppm, 500 ppm, 700 ppm, and 1000 ppm of hydrogen, respectively. In addition, the WTN gas sensor has better stability characteristics for higher operating temperatures.

Similar content being viewed by others

References

E. Şennik, Z. Çolak, N. Kilinç, Z.Z. Öztürk, Synthesis of highly-ordered TiO2 nanotubes for a hydrogen sensor. Int. J. Hydrogen Energy 35(9), 4420–4427 (2010). https://doi.org/10.1016/j.ijhydene.2010.01.100

X. Xia, W. Wu, Z. Wang, Y. Bao, Z. Huang, Y. Gao, A hydrogen sensor based on orientation aligned TiO2 thin films with low concentration detecting limit and short response time. Sensors Actuators, B Chem. 234, 192–200 (2016). https://doi.org/10.1016/j.snb.2016.04.110

L. De Luca et al., Hydrogen sensing characteristics of Pt/TiO2/MWCNTs composites. Int. J. Hydrogen Energy 37(2), 1842–1851 (2012). https://doi.org/10.1016/j.ijhydene.2011.10.017

S. A. Mohd Chachuli, M. N. Hamidom, M. S. Mamat, M. Ertugurul, N. Abdullah, in Hydrogen gas sensing of TiO2/MWCNT thick film via screen-printing technique (2019) https://doi.org/10.1109/SENSORSNANO44414.2019.8940042

A. Kılıç, O. Alev, O. Özdemir, L.Ç. Arslan, S. Büyükköse, Z.Z. Öztürk, The effect of Ag loading on gas sensor properties of TiO2 nanorods. Thin Solid Films 726, 138662 (2021). https://doi.org/10.1016/j.tsf.2021.138662

Y. Bao, P. Wei, X. Xia, Z. Huang, K. Homewood, Y. Gao, Remarkably enhanced H2 response and detection range in Nb doped rutile/anatase heterophase junction TiO2 thin film hydrogen sensors. Sensors Actuators B Chem. 301, 127143 (2019). https://doi.org/10.1016/j.snb.2019.127143

Z. Zhu et al., Flexible and lightweight Ti3C2Tx MXene@Pd colloidal nanoclusters paper film as novel H2 sensor. J. Hazard. Mater. (2020). https://doi.org/10.1016/j.jhazmat.2020.123054

S.A.M. Chachuli et al., Effects of MWCNTs/Graphene Nanoflakes/MXene addition to TiO2 thick film on hydrogen gas sensing. J. Alloys Compd. 882, 160671 (2021). https://doi.org/10.1016/j.jallcom.2021.160671

M. Kumaresan, M. Venkatachalam, M. Saroja, P. Gowthaman, TiO2 nanofibers decorated with monodispersed WO3 heterostruture sensors for high gas sensing performance towards H2 gas. Inorg. Chem. Commun. 129, 108663 (2021). https://doi.org/10.1016/j.inoche.2021.108663

H. Li et al., Mesoporous WO3-TiO2 heterojunction for a hydrogen gas sensor. Sensors Actuators B Chem. (2021). https://doi.org/10.1016/j.snb.2021.130035

M. Radecka et al., TiO2-based nanopowders for gas sensor. Ceram. Mater. 64(4), 545–549 (2010)

M. Shasti, A. Mortezaali, The effect of nitrogen doping of TiO2 compact blocking layers on perovskite solar cell performance. Solid State Sci. 92(April), 68–75 (2019). https://doi.org/10.1016/j.solidstatesciences.2019.03.024

X. Su, Q. He, Y.E. Yang, G. Cheng, D. Dang, L. Yu, Free-standing nitrogen-doped TiO2 nanorod arrays with enhanced capacitive capability for supercapacitors. Diam. Relat. Mater. 114, 108168 (2021). https://doi.org/10.1016/j.diamond.2020.108168

B. Zhang, Y. Tian, F. Chi, S. Liu, Synthesis of nitrogen-doped carbon embedded TiO2 films for electrochromic energy storage application. Electrochim. Acta 390, 138821 (2021). https://doi.org/10.1016/j.electacta.2021.138821

Y. Qu, S. Zhu, X. Dong, H. Huang, M. Qi, Nitrogen-doped TiO2 nanotube anode enabling improvement of electronic conductivity for fast and long-term sodium storage. J. Alloys Compd. 889, 161612 (2021). https://doi.org/10.1016/j.jallcom.2021.161612

J. Yu et al., A one-pot synthesis of nitrogen doped porous MXene/TiO2 heterogeneous film for high-performance flexible energy storage. Chem. Eng. J. 426, 130765 (2021). https://doi.org/10.1016/j.cej.2021.130765

Y. Song, P. Liu, W. Wu, Q. Zhou, High-performance colossal permittivity for textured (Al+Nb) co-doped TiO2 ceramics sintered in nitrogen atmosphere. J. Eur. Ceram. Soc. 41(7), 4146–4152 (2021). https://doi.org/10.1016/j.jeurceramsoc.2021.02.029

E. Smecca et al., Nitrogen doped spongy TiO2 layers for sensors application. Mater. Sci. Semicond. Process. 98, 44–48 (2019). https://doi.org/10.1016/j.mssp.2019.03.012

S. A. M. Chachuli, M. N. Hamidon, M. S. Mamat, M. Ertugrul, in Detecting Hydrogen Using TiO2-B2O3 at Different Operating Temperature. 2018 IEEE Int. Conf. Semicond. Electron., pp. 37–40 (2018)

M. Sánchez, M.E. Rincón, Sensor response of sol–gel multiwalled carbon nanotubes-TiO2 composites deposited by screen-printing and dip-coating techniques. Sensors Actuators B Chem. 140, 17–23 (2009). https://doi.org/10.1016/j.snb.2009.04.006

S. Agarwal et al., An efficient hydrogen gas sensor based on hierarchical Ag/ZnO hollow microstructures. Sensors Actuators B Chem. 346, 130510 (2021). https://doi.org/10.1016/j.snb.2021.130510

A. Debataraja, D.W. Zulhendri, B. Yuliarto, Nugraha, Hiskia, B. Sunendar, Investigation of nanostructured SnO2 synthesized with polyol technique for CO gas sensor applications. Proc. Eng. 170, 60–64 (2017). https://doi.org/10.1016/j.proeng.2017.03.011

S.S. Rane, D.A. Kajale, S.S. Arbuj, S.B. Rane, S.W. Gosavi, Hydrogen, ethanol and ammonia gas sensing properties of nano-structured titanium dioxide thick films. J. Mater. Sci. Mater. Electron. 28, 9011–9016 (2017). https://doi.org/10.1007/s10854-017-6632-0

S.D. Bakrania, M.S. Wooldridge, The effects of two thick film deposition methods on tin dioxide gas sensor performance. Sensors 9(9), 6853–6868 (2009). https://doi.org/10.3390/s90906853

H. Li et al., Mesoporous WO3-TiO2 heterojunction for a hydrogen gas sensor. Sensors Actuators B Chem. 341, 130035 (2021). https://doi.org/10.1016/j.snb.2021.130035

N. Bârsan, M. Hübner, U. Weimar, Conduction mechanisms in SnO2 based polycrystalline thick film gas sensors exposed to CO and H2 in different oxygen backgrounds. Sensors Actuators B Chem. 157(2), 510–517 (2011). https://doi.org/10.1016/j.snb.2011.05.011

L. Yadava, R. Verma, R. Dwivedi, Sensing properties of CdS-doped tin oxide thick film gas sensor. Sensors Actuators B Chem. 144(1), 37–42 (2010). https://doi.org/10.1016/j.snb.2009.10.013

S. AmaniahMohdChachuli, M. Nizar Hamidon, M. Ertugrul, M.S. Mamat, H. Jaafar, N.H. Shamsudin, TiO2/B2O3 thick film gas sensor for monitoring carbon monoxide at different operating temperatures. J. Phys. Conf. Ser. 1432(1), 012040 (2020). https://doi.org/10.1088/1742-6596/1432/1/012040

V. Guidi et al., Gas sensing through thick film technology. Sensors Actuators B Chem. 84(1), 72–77 (2002). https://doi.org/10.1016/S0925-4005(01)01077-2

A.A. Tomchenko, G.P. Harmer, B.T. Marquis, J.W. Allen, Semiconducting metal oxide sensor array for the selective detection of combustion gases. Sensors Actuators B Chem. 93(1–3), 126–134 (2003). https://doi.org/10.1016/S0925-4005(03)00240-5

M. Ehsani, M.N. Hamidon, A. Toudeshki, M.H.S. Abadi, S. Rezaeian, CO2 gas sensing properties of screen-printed La2O3/SnO2 thick film. IEEE Sens. J. 16(18), 6839–6845 (2016)

H.W. Lin, C.P. Chang, W.H. Hwu, M. Der Ger, The rheological behaviors of screen-printing pastes. J. Mater. Process. Technol. 197(1–3), 284–291 (2008). https://doi.org/10.1016/j.jmatprotec.2007.06.067

S.A. MohdChachuli, M.N. Hamidon, M. Ertugrul, M.S. Mamat, H. Jaafar, N. Aris, Influence of B2O3 addition on the properties of TiO2 thick film at various annealing temperatures for hydrogen sensing. J. Electron. Mater. (2020). https://doi.org/10.1007/s11664-020-08059-0

S.A. MohdChachuli, M.N. Hamidon, M.S. Mamat, M. Ertugrulc, N.H. Abdullah, Response of TiO2/MWCNT/B2O3 gas sensor to hydrogen using different organic binder. Mater. Sci. Semicond. Process. 99, 140–148 (2019). https://doi.org/10.1016/j.mssp.2019.04.009

Y. Bessekhouad, D. Robert, J.V. Weber, Synthesis of photocatalytic TiO2 nanoparticles: optimization of the preparation conditions. J. Photochem. Photobiol. A Chem. 157(1), 47–53 (2003). https://doi.org/10.1016/S1010-6030(03)00077-7

K. Zakrzewska, M. Radecka, TiO2-based nanomaterials for gas sensing—influence of anatase and rutile contributions. Nanoscale Res. Lett. 12(89), 1–8 (2017). https://doi.org/10.1186/s11671-017-1875-5

W.E. Garner, L.W. Reeves, The thermal decomposition of silver oxide. Trans. Faraday Soc. 59, 254–260 (1954)

A. Monamary, K. Vijayalakshmi, Substantial effect of palladium overlayer deposition on the H2 sensing performance of TiO2/ITO nanocomposite. Ceram. Int. 44(18), 22957–22962 (2018). https://doi.org/10.1016/j.ceramint.2018.09.093

H. Zhang et al., Extending the detection range and response of TiO2 based hydrogen sensors by surface defect engineering. Int. J. Hydrogen Energy 45(35), 18057–18065 (2020). https://doi.org/10.1016/j.ijhydene.2020.04.190

A. Monamary, K. Vijayalakshmi, S.D. Jereil, Fe overlayered hybrid TiO2/ITO nanocomposite sensor for enhanced hydrogen sensing at room temperature by novel two step process. Sensors Actuators B Chem. 287, 278–289 (2019). https://doi.org/10.1016/j.snb.2019.02.049

D. Wang et al., Pd nanocrystal sensitization two-dimension porous TiO2 for instantaneous and high efficient H2 detection. J. Colloid Interface Sci. 597, 29–38 (2021). https://doi.org/10.1016/j.jcis.2021.03.107

S. Mao et al., High performance hydrogen sensor based on Pd/TiO2 composite film. Int. J. Hydrogen Energy 43(50), 22727–22732 (2018). https://doi.org/10.1016/j.ijhydene.2018.10.094

K.C. Lee, Y.J. Chiang, Y.C. Lin, F.M. Pan, Effects of PdO decoration on the sensing behavior of SnO2 toward carbon monoxide. Sensors Actuators B Chem. 226, 457–464 (2016). https://doi.org/10.1016/j.snb.2015.12.011

A. Dey, Semiconductor metal oxide gas sensors: a review. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 229, 206–217 (2018). https://doi.org/10.1016/j.mseb.2017.12.036

Author information

Authors and Affiliations

Contributions

Formal analysis and investigation: ME, OC, NHS; Writing—original draft preparation: SAMC; Supervision: MNH, MSM.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohd Chachuli, S.A., Hamidon, M.N., Ertugrul, M. et al. Comparative analysis of hydrogen sensing based on treated-TiO2 in thick film gas sensor. Appl. Phys. A 128, 596 (2022). https://doi.org/10.1007/s00339-022-05738-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-022-05738-z