Abstract

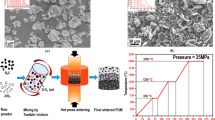

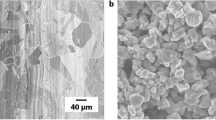

The combination of nanofluids and micro-texture is an established method to improve the tribological properties of TiC-based ceramics (TC). Due to the limitations of nature and function, the mono-type nanoparticle is limited for improvement in lubrication, heat transfer and other aspects. In this study, a new nanofluid based on magnetic Fe3O4 nanoparticles loaded with multi-walled carbon nanotubes (CNTs) was developed by the co-precipitation method as a lubricant to improve the thermal and tribological properties. Firstly, the surfactant with the best adaptability to Fe3O4@CNTs was selected by a visible spectrophotometer to prepare nanofluids with different volumetric concentrations. Then, the micron-grooves were prepared on the tool surface by laser micromachining technology. The tribological properties and contact angles were measured by the ball-on-disc friction method and angle measurement method, respectively. The results show that compared with the traditional water-based cutting fluid and TC, the contact angle, coefficient of friction, and flashpoint temperature of 0.5 vol% Fe3O4@CNTs nanolubricants and textured TiC-based ceramics (TTC) were reduced by 29.17%, 44.69% and 48.28%. The lubrication and heat dissipation mechanism of Fe3O4@CNTs nanofluids on the surface of TTC were also revealed.

Similar content being viewed by others

References

C.X. Liu, J.H. Zhang, J.L. Sun, X.H. Zhang, Tribological properties of pressureless sintered alumina matrix ceramic materials improved by diopside. J. Eur. Ceram. 28, 199–204 (2008)

J.X. Deng, H. Zhang, Z. Wu et al., Unlubricated friction and wear behaviors of Al2O3/TiC ceramic cutting tool materials from high temperature tribological tests. Int. J. Refract. Met. Hard. Mat. 35, 17–26 (2012)

L.P. Wu, Z.J. Xie, G. Le et al., Investigation of the tribological behavior of graphene oxide nanoplates as lubricant additives for ceramic/steel contact. Tribol. Int. 128, 113–120 (2018)

C.X. Liu, J.L. Sun et al., Microstructure and wear performance of alumina/graphene coating on textured Al2O3/TiC substrate composites. J. Eur. Ceram. 41, 1438 (2020)

J. Souza, M. Nono, M.V. Ribeiro et al., Cutting forces in turning of gray cast iron using silicon nitride based cutting tool. Mater. Des. 30(7), 2715–2720 (2009)

J.X. Deng, Z.X. Duan, D.L. Yun, H. Zhang, X. Ai, J. Zhao, Fabrication and performance of Al2O3/(W, Ti)C+Al2O3/TiC multilayered ceramic cutting tools. Mater. Sci. Eng. A. 527, 1039–1047 (2010)

T.F. Ariff, N.S. Shafie, Z.M. Zahir, Wear analysis of silicon nitride (Si3N4) cutting tool in dry machining of T6061 aluminium alloy. Appl. Mech. Mater. 268–270, 563–567 (2013)

R. Raga, I. Khader, Z. Chlup, A. Kailer, Damage initiation and evolution in silicon nitride under non-conforming lubricated hybrid rolling contact. Wear 360–361, 147–159 (2016)

W. Grabon, W. Koszela, P. Pawlus, S. Ochwat, Improving tribological behavior of piston ring-cylinder liner frictional pair by liner surface texturing. Tribol. Int. 61, 102–108 (2013)

N.P. Suh, M. Mosleh, P.S. Howard, Control of friction. Wear 175, 151–158 (1994)

J.L. Li, D.S. Xiong, J.H. Dai, Z.J. Huang, R. Tyagi, Effect of surface laser texture on friction properties of nickel-based composite. Tribol. Int. 43, 1193–1199 (2010)

X.L. Wang, K. Kato, K. Adachi, K. Aizawa, Load carrying capacity map for the surface texture design of SiC thrust bearing sliding in water. Tribol. Int. 36, 189–197 (2003)

C. Sinanoglu, Investigation of load carriage capacity of journal bearings by surface texturing. Ind. Lubr. Tribol. 61, 261–270 (2009)

Q. Allen, B. Raeymaekers, Surface texturing of prosthetic hip implant bearing surfaces: a review. J. Tribol. (2020). https://doi.org/10.1115/1.4048409

T. Roy et al., Improved friction and wear performance of micro dimpled ceramic- on-ceramic interface for hip joint arthroplasty. Ceram. Int. 41(1), 681–690 (2015)

Y. Ding, L.J. Yang, B. Cheng, X.L. Wang, Y. Wang, H. Xie, Investigations on femtosecond laser-modified microgroove-textured cemented carbide YT15 turning tool with promotion in cutting performance. Int. J. Adv. Manuf. Technol. 96, 1–13 (2018)

K.D. Zhang, J.X. Deng, J.L. Sun, J. Chao, Y.Y. Liu, C. Shuai, Effect of micro/nano-scale textures on anti-adhesive wear properties of WC/Co-based TiAlN coated tools in AISI 316 austenitic stainless steel cutting. Appl. Surf. Sci. 355, 602–614 (2015)

Y.J. Han, F. Liu, K.D. Zhang, Q. Huang, X.H. Guo, C.D. Wang, A study on tribological properties of textured Co-Cr-Mo alloy for artificial hip joints. Int. J. Refract. Met. Hard. Mater. 95, 105463 (2021)

O. Ndin, T. Kvak, M. Sarkaya, A.V. Yldrm, Investigation of the influence of MWCNTs mixed nanofluid on the machinability characteristics of PH 13–8 Mo stainless steel. Tribol. Int. 148, 106323 (2020)

Y.X. Cui, M. Ding, T.Y. Sui, W. Zheng, G.C. Qiao, S. Yan, X.B. Liu, Role of nanoparticle materials as water-based lubricant additives for ceramics. Tribol. Int. 142, 105978 (2020)

S. Berber, Y.K. Kwon, D. Tomanek, Unusually high thermal conductivity of carbon nanotubes. Phys. Rev. Lett. 84, 4613 (2000)

P. Kim, L. Shi, A. Majumdar, P. McEuen, Thermal transport measurements of individual multiwalled nanotubes. Phys. Rev. Lett. 87, 215502 (2001)

S.U.S. Choi, Z.G. Zhang, W. Yu, F.E. Lockwood, E.A. Grulke, Anomalous thermal conductivity enhancement in nanotube suspensions. Appl. Phys. Lett. 79(14), 2252–2254 (2001)

J. Zhao, Y.R. Li, Y.Y. He, J.B. Luo, In situ green synthesis of the new sandwich like nanostructure of Mn3O4/graphene as lubricant additives. ACS Appl. Mater. Interfaces. 11, 36931–36938 (2019)

A.K. Sharma, J.K. Katiyar, S. Shubrajit, S. Boy, Influence of alumina/MWCNT hybrid nanoparticle additives on tribological properties of lubricants in turning operations. Friction. 7(02), 65–80 (2019)

C.C. Zhou, X.H. Guo, K.D. Zhang, L. Cheng, Y.Q. Wu, The coupling effect of micro-groove textures and nanofluids on cutting performance of uncoated cemented carbide tools in milling Ti-6Al-4V. J. Mater. Process. Technol. 271, 36–45 (2019)

L. Zhang, X.H. Guo, K.D. Zhang, Y.Q. Wu, Q. Huang, Enhancing cutting performance of uncoated cemented carbide tools by joint-use of magnetic nanofluids and micro-texture under magnetic field. J. Mater. Process. Technol. 284, 116764 (2020)

L. Shi, Y. He, Y. Huang, B. Jiang, Recyclable Fe3O4@CNT nanoparticles for high-efficiency solar vapor generation. Energy Convers. Manag. 149, 401–408 (2017)

S. Khandekar, M.R. Sankar, V. Agnihotri, J. Ramkumar, Nano-cutting fluid for enhancement of metal cutting performance. Mater. Manuf. Process. 27, 963–967 (2012)

D.M. Khan, A. Kausar, S.M. Salman, Buckypapers of polyvinyl chloride/poly (styrene-co-maleic anhydride) blend intercalated grapheme oxide-carbon nanotube nanobifiller: physical property exploration. Fuller. Sci. Technol. 24(3), 202–212 (2016)

D. Wasan, A. Nikolov, K. Kondiparty, The wetting and spreading of nanofluids on solids: role of the structural disjoining pressure. Col. Inter. Sci. 16(4), 344–349 (2011)

L. Wu, G. Le, Z. Xie et al., Improved tribological properties of Si3N4/GCr15 sliding pairs with few layer graphene as oil additives. Ceram. Int. 43(16), 14218–14224 (2017)

S. Neuville, Selective carbon material engineering for improved MEMS and NEMS. Micromachines. 10(8), 539 (2019)

A.G. Khurshudov, M. Olsson, K. Kato, Tribology of unlubricated sliding contact of ceramic materials and amorphous carbon. Wear 205(1–2), 101–111 (1997)

L. Yang, Y. Ding, B. Cheng, J. He, G. Wang, W. Yang, Investigations on femtosecond laser modified micro-textured surface with anti-friction property on bearing steel GCr15. Appl. Surf. Sci. 434, 831–842 (2018)

Acknowledgements

The authors acknowledge the financial support of the National Natural Science Foundation of China (Nos. 51905360, 51805344).

Author information

Authors and Affiliations

Contributions

YZ: Data collection, formal analysis, investigation, data curation, writing (original draft). KZ: Conceptualization, supervision, investigation, writing (review and editing), methodology. XG: Conceptualization, supervision, resources, funding acquisition, methodology, writing (review and editing), project administration. ZL: Data collection, investigation. CW: Methodology, funding acquisition. TL: Conceptualization, supervision, writing (review).

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Guo, X., Li, Z. et al. Study on the tribological properties of Fe3O4@CNTs nanofluids acting on the textured ceramics. Appl. Phys. A 128, 161 (2022). https://doi.org/10.1007/s00339-022-05305-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-022-05305-6