Abstract

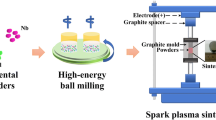

Electrical resistance sintering is a fast method to fabricate metallic samples in the metallurgy field and was used to obtain the Ti-Nb-Sn alloy to be applied as a possible biomaterial. Powders were obtained by mechanical alloying and were then compacted at 193 MPa pressure for 700 ms at several electrical current densities (11, 12 and 13 kA). The structure and microstructure of both powders and samples were evaluated by X-ray diffraction, Field Emission Scanning Electron Microscopy and Electron Backscattered Diffraction. Mechanical properties were evaluated by a microhardness assay and corrosion resistance was performed in Ringer Hartmann’s solution at 37°C. Samples were structured in the α, α” and β phases. The content of the β phase in the samples obtained at 11, 12 and 13 kA was 96.56, 98.12 and 98.02%, respectively. The peripheral zone showed more microporosity than the central zone. The microstructure was also formed by equiaxial bcc-β grains, and the samples obtained at 12 kA presented better microstructure homogeneity. Grain size increased as electric current density rose. The microhardness values fell within the 389–418 HV range and lowered, while electric current density increased. Corrosion tests proved the alloys’ excellent corrosion resistance (0.24–0.45 µA/cm2). The standard deviations of the kinetic parameters of the samples at 11 and 13 kA were much higher in relation to lack of microstructure homogeneity.

Similar content being viewed by others

References

N. Eliaz, Corrosion of metallic biomaterials: a review. Mater. 12, 407 (2019). https://doi.org/10.3390/ma12030407

E.J. Evans, Cell damage in vitro following direct contact with fine particles of titanium, titanium alloy and cobalt-chrome-molybdenum alloy. Biomaterials 442, 713–717 (1994). https://doi.org/10.1016/0142-9612(94)90170-8

J.E. Bowerman, B. Conroy, A universal kit in titanium for immediate replacement of the resected mandible. J. Oral. Surg. 6, 223–228 (1969). https://doi.org/10.1016/s0007-117x(68)80041-1

D.G. Barceloux, J. Toxicol. Clin. Toxicol. 37, 265–278 (1999). https://doi.org/10.1081/clt-100102425

J.K. Marquis, Aluminum neurotoxicity: an experimental perspective. Bull. Environ. Contam. Toxicol. 29, 43–49 (1982). https://doi.org/10.1007/BF01606087

M. Long, H.J. Rack, Titanium alloys in total joint replacement-a materials science perspective. Biomaterials 19, 1621–1639 (1998). https://doi.org/10.1016/S0142-9612(97)00146-4

M. Niinomi, Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A. 3, 231–236 (1998). https://doi.org/10.1016/j.actbio.2006.11.002

H. Kroger, P. Venesmaa, J. Jurvelin, H. Miettinen, O. Suomalainen, E. Alhava, Bone density at the proximal femur after total hip arthroplasty. Clin. Orthop. Relat. 352, 66–74 (1998)

T. Ozaki, H. Matsumoto, S. Watanabe, S. Hanada, Beta Ti alloys with low young’s modulus. Mater. Trans. 45, 2776–2779 (2004). https://doi.org/10.2320/matertrans.45.2776

I.J. Polmear, Overview: recent developments in light alloys. Mater. Trans. 37, 12–31 (1996). https://doi.org/10.2320/matertrans1989.37.12

J.L. Murray, The Nb-Ti (Niobium-Titanium) system. Phase Diagr. 2, 55–61 (1981)

L. Zhu, Q. Zhang, Z. Chen, W. Changdong, C. Ge-Mei, J. Liang, J. Zhanpeng, Z. Ji-Cheng, Measurement of interdiffusion and impurity diffusion coefficients in the bcc phase of the Ti–X (X = Cr, Hf, Mo, Nb, V, Zr) binary systems using diffusion multiples. J. Mater. Sci. 52, 3255–3268 (2017). https://doi.org/10.1007/s10853-016-0614-0

B. Sharma, S.K. Vajpai, K. Ameyama, Synthesis of ternary Ti-25Nb-11Sn alloy by powder metallurgy route using titanium hydride powder. Mater. Trans. 57, 1440–1446 (2016). https://doi.org/10.2320/matertrans.mh201510

M.S. Yahaya, M. Sulaiman, N.H.N.E. Azham Shah, M.H. Ismail, Microstructures and mechanical properties of Ti-Nb alloy at different composition of Nb produced via powder metallurgy route. Mater. Sci. Forum. 863, 14–18 (2016)

J. Lux, Improved manufacture of electric incandescence lamp laments from tungsten or molybdenum or an alloy thereof. GB Patent. 1906

G.F. Taylor, Apparatus for Making Hard Metal Compositions. U.S. Patent 1,896,854, 7 February 1933

F.V. Lenel, Resistance sintering under pressure. J Alloy Compd. 7, 158–167 (1955). https://doi.org/10.1007/BF03377473

T.L. Istomina, A.A. Baidenko, A.I. Raichenko, M.A. Goldberg, A.V. Svechkov, Influence of premolding pressure in electric-discharge sintering on the physicomechanical properties of a copper-tin-abrasive composite. Sov. Powder Metal. Met. Ceram. 22, 957–960 (1983). https://doi.org/10.1007/BF00805559

G.L. Burenkov, A.I. Raichenko, M. Suraeva, Dynamics of interparticle reactions in spherical metal powders during electric sintering. Sov. Powder Metall. Met. Ceram. 26, 709–712 (1987). https://doi.org/10.1007/BF00797175

S. Grasso, Y. Sakka, G. Maizza, Electric current activated/assisted sintering (ECAS): a review of patents 1906–2008. Sci. Technol. Adv. Mater. 10, 053001 (2009)

R. Orrù, R. Licheri, A.M. Locci, A. Cincotti, G. Cao, Consolidation/synthesis of materials by electric current activated/assisted sintering. Mat. Sci. Eng. R Rep. 63, 127–287 (2009). https://doi.org/10.1016/j.mser.2008.09.003

E.A. Olevsky, D.V. Dudina, Field-Assisted Sintering Science and Applications, first ed., Cham, Switzerland, 2018.

A. Fais, A faster FAST: electro-sinter-forging. Metal Powder Rep. 73, 80–86 (2018). https://doi.org/10.1016/j.mprp.2017.06.001

E. Cannella, C.V. Nielsen, N. Bay, Process investigation and mechanical properties of electro sinter forged (ESF) titanium discs. Int. J. Adv. Manuf. Technol. 104, 1985–1998 (2019). https://doi.org/10.1007/s00170-019-03972-z

U. Anselmi-Tamburini, J.R. Groza, Critical assessment: Electrical field/current application. A revolution in materials processing/sintering. Mater. Sci. Technol. 33, 1855–1862 (2017). https://doi.org/10.1080/02670836.2017.1341692

M.C. Rossi, D.L. Bayerlein, J.S. Brandao, J.P.H. Pfeifer, G.S. Rosa, W.M. Silva, L.G. Martinez, M.J. Saeki, A.L.G. Alves, Physical and biological characterizations of TiNbSn/(Mg) system produced by powder metallurgy for use as prostheses material. J Mech. Behav. Biomed. Mater. 115, 104260 (2021). https://doi.org/10.1016/j.jmbbm.2020.104260

M.C. Rossi, D.L. Bayerlein, E.S. Gouvea, V.M.R. Haro, V.A. Escuder, V.B. Amigo, Evaluation of the influence of low Mg content on the mechanical and microstructural properties of beta titanium alloy. J. Mater. Res. Technol. 10, 916–925 (2021). https://doi.org/10.1016/j.jmrt.2020.12.103

G.M.A. Mahran, A.-N.M. Omran, Fabrication of a β Ti–30Nb–4Sn biomedical alloy using mechanical alloying. Sci. Adv. Mater. 10, 1509–1518 (2018). https://doi.org/10.1166/sam.2018.3352

D.R. Adiningsih, E.P. Utomo, The microstructure and mechanical hardness of cast Ti-30Nb-5Sn after solution treatment. IOP Conf Ser Mater Sci Eng. 541, 012049 (2019). https://doi.org/10.1088/1757-899X/541/1/012049

B. Sharma, S.K. Vajpai, K. Ameyama, Synthesis of ternary Ti-25Nb-11Sn alloy by powder metallurgy route using titanium hydride powder. Mater Trans. 57, 1440–1446 (2016). https://doi.org/10.2320/matertrans.MH201510

P. Li, X. Ma, D. Wang, H. Zhang, Microstructural and mechanical properties of β-Type Ti–Nb–Sn biomedical alloys with low elastic modulus. Metals. 9, 712 (2019). https://doi.org/10.3390/met9060712

S. Cai, L. Wang, J.E. Schaffer, J. Gao, Y. Ren, Influence of Sn on martensitic beta Ti alloys. Mater. Sci. Eng. A. 743, 764–772 (2019). https://doi.org/10.1016/j.msea.2018.11.095

H. Matsumoto, S. Watanabe, S. Hanada, Microstructures and mechanical properties of metastable β TiNbSn alloys cold rolled and heat treated. J Alloys Compd. 439, 146–155 (2007). https://doi.org/10.1016/j.jallcom.2006.08.267

M.F. Ijaz, H.Y. Kim, H. Hosoda, S. Miyazaki, Efect of Sn addition on stress hysteresis and superelastic properties of a Ti–15Nb–3Mo alloy. Scripta Mater. 72–73, 29–32 (2014)

M.A. Lagos, I. Agote, T. Schubert, T. Weissgaerber, J.M. Gallardo, J.M. Montes, L. Prakash, C. Andreouli, V. Oikonomou, D. Lopez, J.A. Calero, Development of electric resistance sintering process for the fabrication of hard metals: Processing microstructure and mechanical properties Abbreviations. Int J Refract Metals Hard Mater. 66, 88–94 (2017). https://doi.org/10.1016/j.ijrmhm.2017.03.005

G.K. Williamson, W.H. Hall, X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1, 22–31 (1953). https://doi.org/10.1016/0001-6160(53)90006-6

A.M. Soufiani, F. Karimzadeh, M. Enayati, Formation mechanism and characterization of nanostructured Ti6Al4V alloy prepared by mechanical alloying. Mater. Des. 37, 152–160 (2012). https://doi.org/10.1016/j.matdes.2011.12.044

L.M. Zou, C. Yang, Y. Long, Z.Y. Xiao, Y.Y. Li, Fabrication of biomedical Ti-35Nb-7Zr-5Ta alloys by mechanical alloying and spark plasma sintering. Powder Metall. 55, 65–70 (2012). https://doi.org/10.1179/1743290111Y.0000000021

J. Málek, F. Hnilica, J. Veselý, B. Smola, Heat treatment and mechanical properties of powder metallurgy processed Ti-35.5 Nb-57Ta beta-titanium alloy. Mater. Charact. 84, 225–231 (2013). https://doi.org/10.1016/j.matchar.2013.08.006

L. Lutterotti, S. Matthies, H.R. Wenk, MAUD: a friendly java program for material analysis using diffraction. IUCr Newsl. CPD. 21, 14–15 (1999)

C.M. Lee, C.P. Ju, J.H.C. Lin, Structure property relationship of cast Ti-Nb alloys. J. Oral Rehabil. 29, 314–322 (2002). https://doi.org/10.1046/j.1365-2842.2002.00825.x

C. Slama, M. Abdellaoui, Microstructure characterization of nanocrystalline (Ti0.9W0.1) C prepared by mechanical alloying. Int. J. Refract. Met. Hard Mater. 54, 270–278 (2016). https://doi.org/10.1016/j.ijrmhm.2015.07.018

H.J. Fecht, Nanostructure formation by mechanical attrition. Nanostruct. Mater. 6, 33–42 (1995)

L. Zhang, X. Guo, Microstructural evolution, thermal stability and microhardness of the Nb–Ti–Si-Based alloy during mechanical alloying. J. Met. 8, 403 (2018). https://doi.org/10.3390/met8060403

A.F. Mohamed, A dislocation model for the minimum grain size obtainable by milling. Acta Mater. 51, 4107–4119 (2003). https://doi.org/10.1016/s1359-6454(03)00230-1

K.V. Sanjay, A. Kei, A novel powder metallurgy processing approach to prepare fine-grained Ti rich TiAl-based alloys from pre-alloyed powders. J. Intermet. 42, 146–155 (2013). https://doi.org/10.1016/j.intermet.2013.06.006

A.L. Patterson, The scherrer formula for X-Ray particle size determination. Phys. Rev. 56, 978–982 (1939). https://doi.org/10.1103/physrev.56.978

P. Singh, A. Abhash, B.N. Yadav, M. Shafeeq, I.B. Singh, D.P. Mondal, Effect of milling time on powder characteristics and mechanical performance of Ti4wt%Al alloy. Powder Technol. 342, 275–287 (2018). https://doi.org/10.1016/j.powtec.2018.09.075

A. Khorsand Zak, W.H. Abd Majid, M.E. Abrishami, R. Yousefi, Solid State Sci. 13, 251 (2011)

L.K. Singh, A. Bhadauria, S. Jana, T. Laha, Effect of sintering temperature and heating rate on crystallite size, densification behaviour and mechanical properties of Al-MWCNT nanocomposite consolidated via spark plasma sintering. Acta Metall Sin-Engl. 31, 1019–1030 (2018). https://doi.org/10.1007/s40195-018-0795-4

B.N. Kim, K. Hiraga, K. Morita, H. Yoshida, Y.J. Park, Y. Sakka, Dynamic grain growth during low-temperature spark plasma sintering of alumina. Scr. Mater. 80, 29–32 (2014). https://doi.org/10.1016/j.scriptamat.2014.02.015

J. Besson, M. Abouaf, Grain growth enhancement in alumina during hot isostatic pressing. Acta Metall. Mater. 39, 2225–2234 (1991). https://doi.org/10.1016/0956-7151(91)90004-K

E.A. Olevsky, S. Kandukuri, L. Froyen, Consolidation enhancement in spark-plasma sintering: impact of high heating rates. J. Appl. Phys. 102, 114913 (2007). https://doi.org/10.1063/1.2822189

B. Sharma, K. Nagano, M. Kawabata, K. Ameyama, Microstructure and mechanical properties of hetero-designed Ti-25Nb-25Zr alloy fabricated by powder metallurgy route. Lett. Mater. 9, 511–516 (2019). https://doi.org/10.3390/met10121615

K. Ameyama, N. Horikawa, M. Kawabata, Unique mechanical properties of harmonic structure designed materials. Tetsu-to-Hagane. 105, 124–126 (2019)

H.R. Wenk, P. Van Houtte, Texture and anisotropy. Rep. Prog. Phys. 67, s1367 (2004)

J.W. Christian, Proc. ICSMA 2: 2nd Int. Conf. on Strength of Metals and Alloys Vol. 1, ASM (1970) p. 29.

M. Kawata. X-Ray analysis of residual stress and texture in ground carbon steels; Master theses; Toyohashi Univ. Tech., March 45–47, (1982).

A. Biesiekierski, J. Wang, M. Abdel-Hady Gepreel, C. Wen, A new look at biomedical Ti-based shape memory alloys. Acta Biomater. 8, 1661–1669 (2012). https://doi.org/10.1016/j.actbio.2012.01.018

Y. Li, C. Yang, H. Zhao, S. Qu, X. Li, Y. Li, New developments of ti-based alloys for biomedical applications. Materials. 7, 1709–1800 (2014). https://doi.org/10.3390/ma7031709

M. Niinomi, Recent metallic materials for biomedical applications. Metall. Mater. Trans. A. 33, 477–486 (2002). https://doi.org/10.1007/s11661-002-0109-2

H.C. Hsu, S.C. Wu, Y.S. Hong, W.F. Ho, Mechanical properties and deformation behavior of as-cast Ti-Sn alloys. J. Alloys Compd. 479, 390–394 (2009). https://doi.org/10.1016/j.jallcom.2008.12.064

J.L. Murray. In :J. L.Murray (Ed.),Alloy Phase Diagrams, ASM International, Materials Park, Ohio, 1987, p. 294.

W.D. Callister, Materials Science and Engineering: An Introduction, Seventhed (Wiley, New York, 2007)

T. Sato, S. Hukai, Y.C. Huang, The Ms points of binary titanium alloys. J. Aust. Inst. Met. 5, 149–153 (1960)

E. Gouvea, M. Lagos, A. Vicente, D. Lopez, I. Agote, J.A. Calero, V. Amigó, Ti-27Nb-8Mo Beta Alloy Developed by Electric Resistance Sintering. Euro PM 2019 – Spark Plasma Sintering.

A. Amigó-Mata, E. Gouvea, M.A. Lagos, D. López, I. Jesús-Romero, I. Agote, A. Vicente-Escuder, J.A. Calero, Effect of ERS Process Parameters on the Microstructure and Mechanical Properties of Ti6Al4V, Euro PM2019 – Spark Plasma Sintering.

E.P. Utomo, I. Kartika, A. Anawati, Effect of Sn on mechanical hardness of as-cast Ti-Nb-Sn alloys. (2018) https://doi.org/10.1063/1.5038328.

S.S. Da Rocha, G.L. Adabo, G.E.P. Henriques, M.A. Nóbilo, Vickers hardness of cast commercially pure titanium and Ti-6Al-4V alloy submitted to heat treatments. Braz. Dent. J. 17, 126–129 (2006). https://doi.org/10.1590/s0103-64402006000200008

C.R.M. Afonso, K. Martinez-Orozco, V. Amigo, C.A.D. Rovere, J.E. Spinelli, C.S. Kiminami, Characterization, corrosion resistance and hardness of rapidly solidified Ni-Nb alloys. J. Alloys Compd. 829, 154529 (2020). https://doi.org/10.1016/j.jallcom.2020.154529

N. Mavros, T. Larimian, J. Esqivel, R.K. Gupta, R. Contieri, T. Borkar, Spark plasma sintering of low modulus titanium-niobium-tantalum-zirconium (TNTZ) alloy for biomedical applications. Mater. Design. 183, 108163 (2019). https://doi.org/10.1016/j.matdes.2019.108163

Q. Kong, X. Lai, X. An, W. Feng, C. Lu, J. Wu, C. Wu, L. Wu, Q. Wang, Mater. Today Commun. 23, 101130 (2020). https://doi.org/10.1016/j.mtcomm.2020.101130

F.E.T. Heakal, K.A. Awad, Electrochemical corrosion and passivation behavior of titanium and its Ti-6AL-4V alloy in low and highly concentrated HBr solutions. Int. J. Electrochem. Sci. 7, 6539–6554 (2011)

A.A. Ahmed, M. Mhaede, M. Wollmann, L. Wagner, Effect of micro shot peening on the mechanical properties and corrosion behavior of two microstructure Ti–6Al–4V alloy. Appl. Surf. Sci. 363, 50–58 (2016). https://doi.org/10.1016/j.apsusc.2015.12.019

Acknowledgements

The authors thank the AMES Company for the materials development.

Funding

This work was supported by the Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP) [grant: 2019/24237–6]; Ministerio de Economía y Competitividad de España for the research project RTI2018-097810-B-I00 and the European Commission through FEDER.

Author information

Authors and Affiliations

Contributions

Conceptualization: [Mariana Correa Rossi], Methodology: [Mariana Correa Rossi], Formal analysis and research: [Mariana Correa Rossi], [Vicente Amigó Borrás]; Writing—original draft preparation: [Mariana Correa Rossi]; Writing—review and editing: [Margarida Saeki],[Vicente Amigó Borrás]; Data acquisition [Eber de Santi Gouvêa], [Montserrat Vicenta Haro Rodríguez], [Angel Vicente Escuder] Funding acquisition: [Mariana Correa Rossi],[Vicente Amigó Borrás]; Supervision: [Vicente Amigó Borrás].

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that may have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rossi, M.C., de Santi Gouvêa, E., Rodríguez, M.V.H. et al. Study of the current density of the electrical resistance sintering technique on microstructural and mechanical properties in a β Ti-Nb-Sn ternary alloy. Appl. Phys. A 127, 796 (2021). https://doi.org/10.1007/s00339-021-04937-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04937-4