Abstract

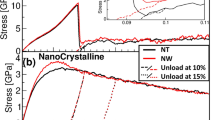

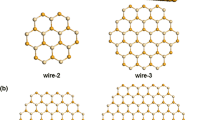

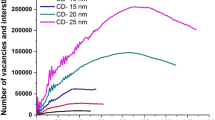

The mechanical properties of copper (Cu) nanowires (NWs) wrapped by carbon nanotube (CNT) under compression are studied by molecular dynamics simulations. By constructing a new structural model, which contains a Cu NW and a CNT that is denoted as CNT@Cu, the mechanical properties, deformation process and structural transformation are investigated in terms of stress–strain relationship, number of stacking faults (SFs) and dislocations, average bond length and atomic configurations. Results show that stress–strain exhibits two nonlinear elastic contraction stages and two intervening stages of inelastic deformation. The stress of Cu NW is almost not affected by the generation and migration activities of SFs but strongly depends on the increasing ratio of SFs due to the supporting of CNT. The inelastic plastic deformation is initiated by nucleation of partial dislocations on the {110} surface and then propagates to interior along the {111} close-packed planes. Wrapped by CNT, a unique structural transformation of compressed Cu NW is found, which is from < 100 > /{111} to < 100 > /{100} through the annihilation of {111} SFs planes and formation of {100} SFs planes along the [100] crystallographic orientations. The < 100 > /{100}-structured wire would undergo nonlinear elastic contraction until to a certain large strain, and then bend near the middle part before NW fractures eventually at a very high stain. What’s more, the < 100 > /{100}-structured Cu NW possess high reversibility under unloading and an interestingly structural reverse transformation from < 100 > /{100} to < 100 > /{111} structure is observed prior to the fracture of NW at a high strain for the CNT@Cu model due the support of CNT. The ultimate compressive elastic strength of {100} (UCES-{100}) and ultimate elastic stain will decrease as the temperature increases from 10 to 500 K. The UCES of pristine (UCES-pristine) and UCSE-{100} decrease as diameter decreases.

Similar content being viewed by others

References

W.-X. Zhou, K.-Q. Chen, L.-M. Tang, L.-J. Yao, Phonon thermal transport in InAs nanowires with different size and growth directions. Phys. Lett. A 377, 3144–3147 (2013)

B. Wu, A. Heidelberg, J.J. Boland, Mechanical properties of ultrahigh-strength gold nanowires. Nat. Mater. 4, 525–529 (2005)

H. Huan, L. Chen, X. Ye, Strain Effect on the Electronic and Optical Properties of CdSe Nanowires. Nanoscale Res. Lett. 12, 178 (2017)

C. Peng, Y. Ganesan, Y. Lu, J. Lou, Size dependent mechanical properties of single crystalline nickel nanowires. J. Appl. Phys. 111, 063524 (2012)

G. Aral, Y.-J. Wang, S. Ogata, A.C. Van Duin, Effects of oxidation on tensile deformation of iron nanowires: insights from reactive molecular dynamics simulations. J. Appl. Phys. 120, 135104 (2016)

B. Ma, Q. Rao, Y. He, Molecular dynamics simulation of temperature effect on tensile mechanical properties of single crystal tungsten nanowire. Comput. Mater. Sci. 117, 40–44 (2016)

Y. Gao, H. Wang, J. Zhao, C. Sun, F. Wang, Anisotropic and temperature effects on mechanical properties of copper nanowires under tensile loading. Comput. Mater. Sci. 50, 3032–3037 (2011)

Y.-H. Wen, Q. Wang, K.M. Liew, Z.-Z. Zhu, Compressive mechanical behavior of Au nanowires. Phys. Lett. A 374, 2949–2952 (2010)

S. Lee, B. Lee, M. Cho, Compressive pseudoelastic behavior in copper nanowires. Phys. Rev. B 81, 224103 (2010)

H. Zhan, Y. Gu, Theoretical and numerical investigation of bending properties of Cu nanowires. Comput. Mater. Sci. 55, 73–80 (2012)

S.D. Nath, Elastic, elastic–plastic properties of Ag, Cu and Ni nanowires by the bending test using molecular dynamics simulations. Comput. Mater. Sci. 87, 138–144 (2014)

Y. Gao, F. Wang, T. Zhu, J. Zhao, Investigation on the mechanical behaviors of copper nanowires under torsion. Comput. Mater. Sci. 49, 826–830 (2010)

H.F. Zhan, Y.T. Gu, C. Yan, P.K. Yarlagadda, Numerical exploration of the defect’s effect on mechanical properties of nanowires under torsion. Adv. Mater. Res. Trans. Tech. Publ. 335, 498-501 (2011)

L. Zhao, Y. Liu, The influence mechanism of the strain rate on the tensile behavior of copper nanowire. Sci. China Technol. Sci. 62, 2014–2020 (2019)

V.K. Sutrakar, D.R. Mahapatra, Formation of stable ultra-thin pentagon Cu nanowires under high strain rate loading. J. Phys.: Condens. Matter 20, 335206 (2008)

Z. Wu, Y. Zhang, M. Jhon, J. Greer, D. Srolovitz, Nanostructure and surface effects on yield in Cu nanowires. Acta Mater. 61, 1831–1842 (2013)

J. Veerababu, U. Manzoor, G. Sainath, S. Goyal, R. Sandhya, Deformation behavior of Cu nanowire with axial stacking fault. Mater. Res. Express 6, 075056 (2019)

H. Zhan, Y. Gu, C. Yan, X.-Q. Feng, P. Yarlagadda, Numerical exploration of plastic deformation mechanisms of copper nanowires with surface defects. Comput. Mater. Sci. 50, 3425–3430 (2011)

H. Xie, F. Yin, T. Yu, G. Lu, Y. Zhang, A new strain-rate-induced deformation mechanism of Cu nanowire: transition from dislocation nucleation to phase transformation. Acta Mater. 85, 191–198 (2015)

S. Iijima, Helical microtubules of graphitic carbon. Nature 354, 56–58 (1991)

J. Bao, Q. Zhou, J. Hong, Z. Xu, Synthesis and magnetic behavior of an array of nickel-filled carbon nanotubes. Appl. Phys. Lett. 81, 4592–4594 (2002)

A. Setlur, J. Lauerhaas, J. Dai, R.P. Chang, A method for synthesizing large quantities of carbon nanotubes and encapsulated copper nanowires. Appl. Phys. Lett. 69, 345–347 (1996)

F. Sun, H. Li, K.M. Liew, Compressive mechanical properties of carbon nanotubes encapsulating helical copper nanowires. Carbon 48, 1586–1591 (2010)

B.-W. Jeong, J.-K. Lim, S.B. Sinnott, Tensile mechanical behavior of hollow and filled carbon nanotubes under tension or combined tension-torsion. Appl. Phys. Lett. 90, 023102 (2007)

H. Huan, B. Fu, X. Ye, The torsional mechanical properties of copper nanowires supported by carbon nanotubes. Phys. Lett. A 381, 481–488 (2017)

S. Nosé, A molecular dynamics method for simulations in the canonical ensemble. Mol. Phys. 52, 255–268 (1984)

W.G. Hoover, Canonical dynamics: equilibrium phase-space distributions. Phys. Rev. A 31, 1695 (1985)

S. Foiles, M. Baskes, M.S. Daw, Embedded-atom-method functions for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, and their alloys. Phys. Rev. B 33, 7983 (1986)

M.S. Daw, M.I. Baskes, Embedded-atom method: derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 29, 6443 (1984)

Y. Mishin, M. Mehl, D. Papaconstantopoulos, A. Voter, J. Kress, Structural stability and lattice defects in copper: Ab initio, tight-binding, and embedded-atom calculations. Phys. Rev. B 63, 224106 (2001)

J. Tersoff, Modeling solid-state chemistry: interatomic potentials for multicomponent systems. Phys. Rev. B 39, 5566 (1989)

H. Akbarzadeh, H. Yaghoubi, Molecular dynamics simulations of silver nanocluster supported on carbon nanotube. J. Colloid Interface Sci. 418, 178–184 (2014)

H. Akbarzadeh, M. Abbaspour, Investigation of melting and freezing of Ag–Au alloy nanoclusters supported on carbon nanotube using molecular dynamics simulations. J. Mol. Liq. 216, 671–682 (2016)

Y. Yan, Y. Lei, S. Liu, Tensile responses of carbon nanotubes-reinforced copper nanocomposites: molecular dynamics simulation. Comput. Mater. Sci. 151, 273–277 (2018)

S.-P. Huang, D.S. Mainardi, P.B. Balbuena, Structure and dynamics of graphite-supported bimetallic nanoclusters. Surf. Sci. 545, 163–179 (2003)

M. Allen, D. Tildesley, Computer Simulation of Liquids (Oxford Science, London, 1990)

S. Plimpton, P. Crozier, A. Thompson, LAMMPS-large-scale atomic/molecular massively parallel simulator. Sandia National Lab. 18, 43 (2007)

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995)

A. Stukowski, Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool (http://ovito.org/). Modelling Simul. Mater. Sci, Eng, 18 (2010) 015012.

C.L. Kelchner, S. Plimpton, J. Hamilton, Dislocation nucleation and defect structure during surface indentation. Phys. Rev. B 58, 11085 (1998)

X. Guo, W. Liang, M. Zhou, Mechanism for the pseudoelastic behavior of FCC shape memory nanowires. Exp. Mech. 49, 183–190 (2009)

P.R. Budarapu, R. Gracie, S.-W. Yang, X. Zhuang, T. Rabczuk, Efficient coarse graining in multiscale modeling of fracture. Theoret. Appl. Fract. Mech. 69, 126–143 (2014)

H. Talebi, M. Silani, S.P. Bordas, P. Kerfriden, T. Rabczuk, A computational library for multiscale modeling of material failure. Comput. Mech. 53, 1047–1071 (2014)

Z. Wang, J. Li, F. Gao, W.J. Weber, Tensile and compressive mechanical behavior of twinned silicon carbide nanowires. Acta Mater. 58, 1963–1971 (2010)

I.N. Mastorakos, H.M. Zbib, D.F. Bahr, J. Parsons, M. Faisal, Pseudoelastic behavior of Cu–Ni composite nanowires. Appl. Phys. Lett. 94, 043104 (2009)

F. Ma, K. Xu, Size-dependent theoretical tensile strength and other mechanical properties of [001] oriented Au, Ag, and Cu nanowires. J. Mater. Res. 21, 2810–2816 (2006)

H. Cao, Z. Rui, F. Yang, Mechanical properties of Cu nanowires: effects of cross-sectional area and temperature. Mater. Sci. Eng. A (2020). https://doi.org/10.1016/j.msea.2020.139644

X. Shi-Feng, C. Shang-Da, S. Ai-Kah, The effect of atomic vacancies and grain boundaries on mechanical properties of gan nanowires. Chinese Physics Letters 28, 066201 (2011)

H.S. Park, K. Gall, J.A. Zimmerman, Deformation of FCC nanowires by twinning and slip. J. Mech. Phys. Solids 54, 1862–1881 (2006)

C.-D. Wu, P.-H. Sung, T.-H. Fang, Study of deformation and shape recovery of NiTi nanowires under torsion. J. Mol. Model. 19, 1883–1890 (2013)

H.S. Park, K. Gall, J.A. Zimmerman, Shape memory and pseudoelasticity in metal nanowires. Phys. Rev. Lett. 95, 255504 (2005)

S. Vlassov, B. Polyakov, M. Vahtrus, M. Mets, M. Antsov, S. Oras, A. Tarre, T. Arroval, R. Lõhmus, J. Aarik, Enhanced flexibility and electron-beam-controlled shape recovery in alumina-coated Au and Ag core–shell nanowires. Nanotechnology 28, 505707 (2017)

H. Wu, Molecular dynamics study on mechanics of metal nanowire. Mech. Res. Commun. 33, 9–16 (2006)

S. Koh, H. Lee, C. Lu, Q. Cheng, Molecular dynamics simulation of a solid platinum nanowire under uniaxial tensile strain: Temperature and strain-rate effects. Phys. Rev. B 72, 085414 (2005)

S.K. Sankaranarayanan, V.R. Bhethanabotla, B. Joseph, Molecular dynamics simulation of temperature and strain rate effects on the elastic properties of bimetallic Pd-Pt nanowires. Phys. Rev. B 76, 134117 (2007)

P.-Y. Yang, S.-P. Ju, Z.-M. Lai, J.-Y. Hsieh, J.-S. Lin, The mechanical properties and thermal stability of ultrathin germanium nanowires. RSC Adv. 6, 105713–105722 (2016)

T. Xu, Z. Zhu, S. Geng, H. Song, Molecular dynamics study of effect of hydrogen atoms on mechanical properties of α-Fe nanowires. Phys. Lett. A 381, 3222–3227 (2017)

X. Zhou, H. Zhou, X. Li, C. Chen, Size effects on tensile and compressive strengths in metallic glass nanowires. J. Mech. Phys. Solids 84, 130–144 (2015)

Y. Gan, B. Zhang, Atomistic study on size-dependent mechanical properties of monatomic tantalum metallic glass nanowires. J. Non-Cryst. Solids 546, 120285 (2020)

G. Aral, Oxide shell layer influences on size-dependent tensile and compressive mechanical properties of iron nanowires: a ReaxFF molecular dynamics study. J. Appl. Phys. 126, 135109 (2019)

M. Nasr Esfahani, B.E. Alaca, A review on size-dependent mechanical properties of nanowires. Adv. Eng. Mater. 21, 1900192 (2019)

Acknowledgements

This work is supported by the Science and Technology Research program of Jiangxi Education Department (No. GJJ208909).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Fu, B., Zhang, Z., Li, L. et al. Compressive properties and behavior of copper nanowires wrapped by carbon nanotube. Appl. Phys. A 127, 787 (2021). https://doi.org/10.1007/s00339-021-04935-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04935-6