Abstract

In this paper, a mixed sintering accelerator of colophony and cetyltrimethyl ammonium bromide (CTAB) was developed to improve the sintering properties of Cu nanoparticles (NPs) paste. With the synergy effect of the mixed sintering accelerator, Cu NPs paste could be well sintered at 260 °C for 30 min under a pressure of 2 MPa, and the shear strength was greatly improved from 15 to 33 MPa. The fracture morphology of the Cu NPs joint transformed from brittle interface failure features to ductile dimple features, and the porosity in the sintered layer was significantly reduced. XRD analysis further confirmed that the synergy of colophony and CTAB could effectively remove the oxides in the Cu NPs paste during sintering, and thereby improve the sintering properties. This work can provide an applicable approach to improve the sintering properties of metal NPs and help to understand the synergy effect of sintering accelerators on the bonding behaviors of metal nanoparticles at low temperatures.

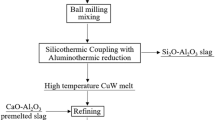

Graphic abstract

Similar content being viewed by others

References

V.R. Manikam, K.Y. Cheong, Die attach materials for high temperature applications: a review. Ieee Trans. Compon. Packag. Manuf. Technol. 1, 457 (2011)

A. Hu, J.Y. Guo, H. Alarifi, G. Patane, Y. Zhou, G. Compagnini, C.X. Xu, Low temperature sintering of Ag nanoparticles for flexible electronics packaging. Appl. Phys. Lett. 97, 153117 (2010)

J. Fan, T. Shi, XiangXu Tao, T. Zhou, J. Li, Z. Tang, G. Liao, Yu. Xing, The Cu-Cu self-propagating reaction joining with different thickness of tin. J. Alloys Compd. 735, 1189 (2018)

B.U. Hwang, K.H. Jung, K.D. Min, C.J. Lee, S.B. Jung, Pressureless Cu-Cu bonding using hybrid Cu-epoxy paste and its reliability. J. Mater. Sci.-Mater. Electron. 32, 3054 (2021)

Y. Liu, Fu. Haifeng, F. Sun, H. Zhang, X. Kong, T. Xin, Microstructure and mechanical properties of as-reflowed Sn58Bi composite solder pastes. J. Mater. Process. Technol. 238, 290 (2016)

J.M. Song, H.Y. Chuang, T.X. Wen, Thermal and tensile properties of Bi-Ag alloys. Metall. Mater. Trans. A 38A, 1371 (2007)

X. Zhong, Wu. Xinke, W. Zhou, K. Sheng, An All-SiC high-frequency boost DC-DC converter operating at 320 degrees C junction temperature. IEEE Trans. Power Electron. 29, 5091 (2014)

Z.X. Zhu, C.C. Li, L.L. Liao, C.K. Liu, C.R. Kao, Au-Sn bonding material for the assembly of power integrated circuit module. J. Alloys Compd. 671, 340 (2016)

Y. Zuo, J. Shen, Xu. Heng, R. Gao, Effect of different sizes of Cu nanoparticles on the shear strength of Cu-Cu joints. Mater. Lett. 199, 13 (2017)

L. Del Carro, A.A. Zinn, P. Ruch, F. Bouville, A.R. Studart, T. Brunschwiler, Oxide-free copper pastes for the attachment of large-area power devices. J. Electron. Mater. 48, 6823 (2019)

Y. Mou, Y. Zhang, H. Cheng, Y. Peng, M. Chen, Fabrication of highly conductive and flexible printed electronics by low temperature sintering reactive silver ink. Appl. Surf. Sci. 459, 249 (2018)

Y. Gao, W. Li, C. Chen, H. Zhang, J. Jiu, C.-F. Li, S. Nagao, K. Suganuma, Novel copper particle paste with self-reduction and self-protection characteristics for die attachment of power semiconductor under a nitrogen atmosphere. Mater. Des. 160, 1265 (2018)

S. Deng, X. Zhang, G.D. Xiao, K. Zhang, X. He, S. Xin, X. Liu, A. Zhong, Y. Chai, Thermal interface material with graphene enhanced sintered copper for high temperature power electronics. Nanotechnology 32, 315710 (2021)

H. Fang, C.X. Wang, S.C. Zhou, Q.S. Kang, T. Wang, D.S. Yang, Y.H. Tian, T. Suga, Rapid pressureless and low-temperature bonding of large-area power chips by sintering two-step activated Ag paste. J. Mater. Sci. Mater. Electron. 31, 6497 (2020)

B. Hu, F. Yang, Y. Peng, H.J. Ji, S.H. Yang, M. Yang, M.Y. Li, Rapid formation of Cu-Cu joints with high shear strength using multiple-flocculated Ag nanoparticle paste. J. Mater. Sci. Mater. Electron. 30, 8071 (2019)

K.-L. Lin, E.-Y. Chang, L.-C. Shih, Evaluation of Cu-bumps with lead-free solders for flip-chip package applications. Microelectron. Eng. 86, 2392 (2009)

C.C. Yang, Y.W. Mai, Thermodynamics at the nanoscale: a new approach to the investigation of unique physicochemical properties of nanomaterials. Mater. Sci. Eng. R-Rep. 79, 1 (2014)

J.T. Jiu, H. Zhang, S. Nagao, T. Sugahara, N. Kagami, Y. Suzuki, Y. Akai, K. Suganuma, Die-attaching silver paste based on a novel solvent for high-power semiconductor devices. J. Mater. Sci. 51, 3422 (2016)

H.Q. Zhang, G.S. Zou, L. Liu, H. Tong, Y. Li, H.L. Bai, A.P. Wu, Synthesis of silver nanoparticles using large-area arc discharge and its application in electronic packaging. J. Mater. Sci. 52, 3375 (2017)

T. Yamakawa, T. Takemoto, M. Shimoda, H. Nishikawa, K. Shiokawa, N. Terada, Influence of joining conditions on bonding strength of joints: efficacy of low-temperature bonding using Cu nanoparticle paste. J. Electron. Mater. 42, 1260 (2013)

J. Liu, H. Chen, H. Ji, M. Li, Highly conductive Cu-Cu Joint formation by low-temperature sintering of formic acid-treated Cu nanoparticles. Acs Appl. Mater. Interfaces (2016). https://doi.org/10.1021/acsami.6b10280

C. Lee, N.R. Kim, J. Koo, Y.J. Lee, H.M. Lee, Cu-Ag core-shell nanoparticles with enhanced oxidation stability for printed electronics. Nanotechnology 26, 455601 (2015)

Y. Zuo, J. Shen, Hu. Youdian, R. Gao, Improvement of oxidation resistance and bonding strength of Cu nanoparticles solder joints of Cu–Cu bonding by phosphating the nanoparticle. J. Mater. Process. Technol. 253, 27 (2018)

T. Ishizaki, R. Watanabe, A new one-pot method for the synthesis of Cu nanoparticles for low temperature bonding. J. Mater. Chem. 22, 25198 (2012)

G. Yang, W. Lin, H. Lai, J. Tong, J. Lei, M. Yuan, Y. Zhang, C. Cui, Understanding the relationship between particle size and ultrasonic treatment during the synthesis of metal nanoparticles. Ultrason. Sonochem. 73, 105497 (2021)

G. Yang, X. Zeng, P. Wang, C. Li, G. Xu, Z. Li, J. Luo, Y. Zhang, C. Cui, Size refinement of copper nanoparticles: a perspective from electrochemical nucleation and growth mechanism. ChemElectroChem 8, 819 (2021)

G. Yang, G. Xu, Q. Li, Y. Zeng, Y. Zhang, M. Hao, C. Cui, Understanding the sintering and heat dissipation behaviours of Cu nanoparticles during low-temperature selective laser sintering process on flexible substrates. J. Phys. D: Appl. Phys. 54, 375304 (2021)

P.M. Raj, P.R. Gangidi, N. Nataraj, N. Kumbhat, Coelectrodeposited solder composite films for advanced thermal interface materials. IEEE Trans Compon Packag Manuf Technol 3, 989 (2013)

M. Grouchko, A. Kamyshny, C.F. Mihailescu, F.A. Dan, S. Magdassi, conductive inks with a “built-in” mechanism that enables sintering at room temperature. ACS Nano 5, 3354 (2011)

X. Dai, T. Zhang, H. Shi, Y. Zhang, T. Wang, Reactive sintering of Cu nanoparticles at ambient conditions for printed electronics. ACS Omega 5, 13416 (2020)

Acknowledgements

We acknowledge the supports of Guangdong Basic and Applied Basic Research (2021A1515011642), National Natural Science Foundation of China (61874155), and the Open Project of the State Key Laboratory of Advanced Materials and Electronic Components (FHR-JS-202011005).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Cao, P., Lin, W. et al. Synergy effect of mixed sintering accelerator on the deoxidation and sintering property improvement of Cu nanoparticles at low temperature. Appl. Phys. A 127, 783 (2021). https://doi.org/10.1007/s00339-021-04924-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04924-9