Abstract

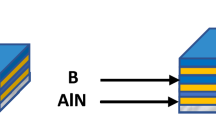

The BAlN thin-film alloy with different thicknesses (∼160–330 nm) is successfully developed on commercial aluminium substrates (5052 grade) using RF reactive sputtering technique at room temperature in Al/B/AlN stacking sequence. The structural, thermal properties and surface topography are studied after annealing at 400 °C in a nitrogen ambient for 1 h. The presence of cubic BAlN thin film is established with the presence of (200) and (220) crystal planes and confirmed by the XRD results. The aluminium nitride (AlN) and boron nitride phases are also confirmed by a clear and very shallow FTIR band reflection spectra between ∼ 512 cm−1 and 912 cm−1; furthermore, the developed BAlN alloy is confirmed from the Raman shift at ∼ 602 cm−1 and ∼ 912 cm−1. The observed continuous thin-film structure with low peak & valley range, low surface roughness with particle size in the range from 80 to 200 nm is indicative of a good surface with lower roughness and a huge decrease in thermal resistance (Rth-tot) by up to 40% in BAlN 2 compared to that of bare Al substrate is achieved. However, similar work with (AlN/B) stacking sequence shows lower improvement in total thermal resistance (Rth) to about 23%; this evidenced the novelty of the work where a material with well-reduced interfacial thermal resistance to about 71% is fabricated at low bond line thickness compared to bare aluminium substrate. It has the capability for good heat spreading at both lower and higher current densities towards efficient and effective thermal management in LED and other devices.

Similar content being viewed by others

References

K. Gordon, “Thermal-management-of-white-leds.pdf” US. DOE, 10–11 (2007). https://www1.eere.energy.gov/buildings/publications/pdfs/ssl/thermal_led_feb07_2.pdf

G. Ke, Y. Tao, Y. Lu, Y. Bian, T. Zhu, H. Guo, Y. Chen, Highly c-axis oriented AlN film grown by unbalanced magnetron reactive sputtering and its electrical properties. J. Alloys Comp. 646, 446–453 (2015). https://doi.org/10.1016/j.jallcom.2015.05.174

S. Subramani, M. Devarajan, Structural and surface analysis of chemical vapor deposited boron-doped aluminum nitride thin film on aluminum substrates. Mater. Sci. Pol. 37(3), 395–403 (2019). https://doi.org/10.2478/msp-2019-0056

B.-D. Hahn, Y. Kim, C.-W. Ahn, J.-J. Choi, J. Ryu, J.-W. Kim, W.-H. Yoon, D.-S. Park, S.-Y. Yoon, B. Ma, Fabrication and characterization of aluminum nitride thick film coated on aluminum substrate for heat dissipation. Cer. Int. 42, 18141–18147 (2016). https://doi.org/10.1016/j.ceramint.2016.08.128

A. Kumar, R. P. Yadav, V. Janyani, M. Prasad, "Structural study of aluminium nitride thin film grown by radio frequency sputtering technique", Int Conf Comput Commun Electron COMPTELIX, Manipal University Jaipur, Malaviya National Institute of Technology Jaipur & IRIS WORLD, July 01–02, pp. 532–535, (2017). https://doi.org/10.1109/COMPTELIX.2017.8004027

Y. Lan, Y. Shi, K. Qi, Z. Ren, H. Liu, Fabrication and characterization of single-phase a-axis AlN ceramic films. Ceram. Int. 44, 8257–8262 (2018). https://doi.org/10.1016/j.ceramint.2018.02.007

J. Liu, Y. Yuan, Z. Ren, Q. Tan, J. Xiong, High-temperature dielectric properties of aluminum nitride ceramic for wireless passive sensing applications. Sensors 15(9), 22660–32267 (2015). https://doi.org/10.3390/s150922660

A. Haider, C. Ozgit-Akgun, E. Goldenberg, A.K. Okyay, N. Biyikli, Low-temperature deposition of hexagonal boron nitride via sequential injection of Triethyl boron and N2/H2 plasma. J. Am. Ceram. Soc. 97(12), 4052–4059 (2014). https://doi.org/10.1111/jace.13213

A.P. Perros, H. Hakola, T. Sajavaara, Influence of plasma chemistry on impurity incorporation in AlN prepared by plasma-enhanced atomic layer deposition. J. Phys. D Appl. Phys. 46, 505502(8pp) (2013). https://doi.org/10.1088/0022-3727/46/50/505502

X. He, Q. Gong, Y. Guo, J. Liu, Microstructure and properties of AlN-BN composites prepared by sparking plasma sintering method. J. Alloy. Compd. 675, 168–173 (2016). https://doi.org/10.1016/j.jallcom.2016.03.058

K. Sato, H. Horibe, T. Shirai, Y. Hotta, H. Nakano, H. Nagai, K. Mitsuishid, K. Wataria, Thermally conductive composite films of hexagonal boron nitride and polyimide with affinity-enhanced interfaces. J. Mater. Chem J. Mater. Chem. 20, 2749–2752 (2010). https://doi.org/10.1039/B924997D

M.S. Idris, S. Subramani, Performance of 9.0 W light-emitting diode on various layers of magnesium oxide thin film thermal interface material. Appl. Phy. A. 126, 646 (2020). https://doi.org/10.1007/s00339-020-03820-y

M. Sundararajan, S. Subramani, M. Devarajan, M. Jaafar, Synthesis and analysis of anodic aluminum oxide-nanopore structure on Al substrates for efficient thermal management in electronic packaging. J. Mat. Sci: Mat. Elect. 31, 9641–9649 (2020). https://doi.org/10.1007/s10854-020-03507-3

N.J.A. Jamaludin, S. Subramani, Thermal performance of LED fixed on CVD processed ZnO thin film on Al substrates at various O2 gas flow rates. AIMS. Mat. Sci. 5(2), 246–256 (2018). https://doi.org/10.3934/matersci.2018.2.246

Z.Y. Ong, S. Shanmugan, D. Mutharasu, Thermal performance on born doped aluminium nitride thin film coated copper substrate of high power LED. J. Sci. Res. Rep. 5(2), 109–119 (2015). https://doi.org/10.9734/JSRR/2015/14232

A.H. El-ladan, S. Subramani, Development of AlNB alloy in (Al/AlN/B) stacking sequence using RF reactive sputtering towards thermal management application. J. Mat. Sci: Mat. in Elec. 32, 577–589 (2021). https://doi.org/10.1007/s10854-020-04840-3

C. Cibert, M. Chatras, C. Champeaux, D. Cros, A. Catherinot, Pulsed laser deposition of aluminum nitride thin films for FBAR applications Applied Surface Science. Appl. Surf. Sci. 253, 8151–8154 (2007). https://doi.org/10.1016/j.apsusc.2007.02.124

J. Li, X. Xiao, X. Xu, J. Lin, Y. Huang, Y. Xue, P. Jin, J. Zou, C. Tang, Activated boron nitride as an effective adsorbent for metal ions and organic pollutants. Sci. Rep. 3, 3208 (2013). https://doi.org/10.1038/srep03208

Th. Uelzen, J. Mu¨ller, Wettability enhancement by rough surfaces generated by thin film technology. Thin. Sol. Fil. 434, 311–315 (2003). https://doi.org/10.1016/S0040-6090(03)00484-X

N.I.D.A. Lopes, L.Á.D.O. Silva, L.D.A. Santos, V.T.L. Buono, Surface characterization of NiTi super elastic and shape memory alloys after electrolytic polishing. Mat. Res. 20(suppl2), 572–579 (2017). https://doi.org/10.1590/1980-5373-mr-2016-0933

M.S. Idris, S. Subramani, M. Devarajan, W. Maryam, Heat transfer enhancement in light-emitting diode packaging employing different molar concentration of magnesium oxide thin films as a heat spreader. Int. J. En. Res. (2020). https://doi.org/10.1002/er.5175

S.G. Pandya, J.P. Corbett, W.M. Jadwisienczak, M.E. Kordesch, Structural characterization and X-ray analysis by Williamson-Hall method for Erbium-doped Aluminum Nitride nanoparticles, synthesized using inert gas condensation technique. Phys. E Low-dim. Sys. Nano. 79, 98–102 (2015). https://doi.org/10.1016/j.physe.2015.12.013

P. Vuong, A. Mballo, S. Sundaram, G. Patriarche, Y. Halfaya, S. Karrakchou, A. Srivastava, K. Krishnan, N.Y. Sama, T. Ayari, S. Gautier, P.L. Voss, J.P. Salvestrini, A. Ougazzaden, Single crystalline boron rich B(Al)N alloys grown by MOVPE. Appl. Phys. Lett. 116, 042101 (2020). https://doi.org/10.1063/1.5135505

W. Han, M. Chen, W. Song, C. Ge, X. Zhang, Construction of hexagonal boron nitride@polystyrene nanocomposite with high thermal conductivity for thermal management application. Cer. Int. 46, 7595–7601 (2020). https://doi.org/10.1016/j.ceramint.2019.11.259

M.S. Idris, S. Subramani, M. Devarajan, W. Maryam, Influence of molar concentration: sol-gel synthesized magnesium oxide thin films for high power light emitting diode thermal management. IOP Conf. Ser. Earth Environ. Sci. 268, 012118 (2019). https://doi.org/10.1088/1755-1315/268/1/012118

M. Imura, Y. Ota, R.G. Banal, M. Liao, Y. Nakayama, M. Takeguchi, Y. Koide, Effect of boron incorporation on structural and optical properties of AlN layers grown by metal-organic vapor phase epitaxy. Phys. Stat. sol. (2018). https://doi.org/10.1002/pssa.201800282

S.S. Imam, R. Adnan, N.H. Mohd Kaus, Influence of yttrium doping on the photocatalytic activity of bismuth oxybromide for ciprofloxacin degradation using indoor fluorescent light illumination. Res. Chem. Intermed. 44, 5357–5376 (2018). https://doi.org/10.1007/s11164-018-3427-8

S. Zhang, D. Wang, L. Song, A novel F-doped BiOCl photocatalyst with enhanced photocatalytic performance. Mat. Chem Phy. 173, 298–308 (2016). https://doi.org/10.1016/j.matchemphys.2016.02.016

J. Yanagimoto, Deformation (Dislocations). In: The International Academy for Produ, ed. by L. Laperrière, G. Reinhart, CIRP Encyclopedia of Production Engineering. (Springer, Berlin, Heidelberg, 2016). https://doi.org/10.1007/978-3-642-35950-7_6503-3

P.R. Jubu, F.K. Yam, Influence of growth duration and nitrogen-ambient on the morphological and structural properties of beta-gallium oxide micro- and nanostructures. Mat. Chem. and Phy 239, 122043 (2020). https://doi.org/10.1016/j.matchemphys.2019.122043

S. Watanabe, T. Takano, K. Jinen, J. Yamamoto, H. Kawanishi, Refractive indices of BxAl1−xN (x = 0–0.012) and ByGa1−yN (y = 0–0.023) epitaxial layers in ultraviolet region. Phys. Stat. Sol. 7, 2691–2694 (2003). https://doi.org/10.1002/pssc.200303549

J.X. Zhanga, H. Chenga, Y.Z. Chena, A. Uddina, S. Yuana, S.J. Gengb, S. Zhang, Growth of AlN films on Si (100) and Si (111) substrates by reactive magnetron sputtering. Surf. Coat. Tech. 198, 68–73 (2005). https://doi.org/10.1016/j.surfcoat.2004.10.075

V.Y. Davydov, Y.E. Kitaev, I.N. Goncharuk, A.N. Smirnov, Phonon dispersion and Raman scattering in hexagonal GaN and AlN. Phys. Rev. B. 58, 12890 (1998). https://doi.org/10.1103/PhysRevB.58.12899

K.P. Bhuvana, J. Elanchezhiyan, N. Gopalakrishnan, T. Balasubramanian, Influence of grain size on the properties of AlN doped ZnO thin film. Mat. Sci in Sem Proc. 14, 84–88 (2011). https://doi.org/10.1016/j.mssp.2011.01.005

Z. Yu, X. Wang, H. Bian, L. Jiao, W. Wu, H. Dai, Enhancement of the heat conduction performance of boron nitride/cellulosic fiber insulating composites. PLoS ONE 13, 1–10 (2018). https://doi.org/10.1371/journal.pone.0200842

M.C. Vu, S.T. Tuan, H.B. Young, J.Y. Min, C.D. Vu, H.L. Jae, K.A. Tae, K. Sung-Ryong, Self-assembly of carbon nanotubes and boron nitride via electrostatic interaction for epoxy composites of high thermal conductivity and electrical resistivity. Mac. Res. 26, 521–528 (2018). https://doi.org/10.1007/s13233-018-6076-2

R.V. Gorbachev, I. Riaz, R.R. Nair, R. Jalil, L. Britnell, B.D. Belle, E.W. Hill, K.S. Novoselov, K. Watanabe, T. Taniguchi, A.K. Geim, P. Blake, Hunting for monolayer boron nitride: optical and Raman signatures. Small 7(4), 465–468 (2011). https://doi.org/10.1002/smll.201001628

Q. Wang, W. Wu, J. Zhang, G. Zhu, R. Cong, Formation, photoluminescence and ferromagnetic characterization of Ce doped AlN hierarchical nanostructures. J. of Alloys and Com. 775, 498–502 (2018). https://doi.org/10.1016/j.jallcom.2018.10.110

L. Shen, T. Chengb, L. Wu, X. Li, Q. Cui, Synthesis and optical properties of aluminum nitride nanowires prepared by arc discharge method. J. of Alloys and Com. 465, 562–566 (2008). https://doi.org/10.1016/j.jallcom.2007.11.007

Y. Song, B. Li, S. Yang, G. Ding, C. Zhang, X. Xie, Ultralight boron nitride aerogels via template-assisted chemical vapor deposition. Sci. Rep. 5, 10337 (2015). https://doi.org/10.1038/srep10337

C. Han, D. Chen, Y. Zhang, D. Xu, Y. Liu, E.S. Kong, Y. Zhang, High potential columnar nanocrystalline AlN films deposited by RF reactive magnetron sputtering. Nan Mic. Let. 4, 40–44 (2012). https://doi.org/10.1007/BF03353690

M. Reusch, S. Chernev, Y. Lu, A. Zukauskait, L. Kirst, K. Ho, M. Datchev, D. Stoychev, V. Lebedev, O. Ambacher, Microstructure and mechanical properties of stress-tailored piezoelectric AlN thin films for electro-acoustic devices. App. Surf. Sci. 407, 307–314 (2017). https://doi.org/10.1016/j.apsusc.2017.02.147

Z. Habibaha, A.N. Arshad, L.N. Ismail, R.A. Bakar, M. Rusop, Chemical solution deposited magnesium oxide films: influence of deposition time on electrical and structural properties. Pro. Eng. 56, 737–742 (2013). https://doi.org/10.1016/j.proeng.2013.03.187

https://www.thermalspray.com/understanding-the-difference-between-thermal-impedance-and-thermal-conductivity/ 1–6 (2020). Accessed on 29 April 2020

“Introduction to Roughness”. https://www.keyence.com/ss/products/microscope/roughness/line/ 1–20 (2010). Accessed on 28 April 2020

S.E. Oraby, A.M. Alaskari, Atomic force microscopy (AFM) topographical surface characterization of multilayer-coated and uncoated carbide inserts. World Acad. Sci. Eng. Tech. Int. J. Mech. Mech. Eng. 4, 10 (2010)

F. Sarvar, D. C. Whalley, P. P. Conway, Thermal interface materials: a review of the state of the art. 1st Electronic System integration Technology Conference, Dresden, 1292–1302 (2006). https://doi.org/10.1109/ESTC.2006.280178

S. Luger, The Technology of Tomorrow for General Lighting Applications. LED Professional Review 4 1–52 (2007). https://www.led-professional.com/downloads/LpR_04_free_23761.pdf. Accessed on 20 April 2020

E. Rudenko, I. Korotash, M. Dyakin, D. Polotsky, M. Belogolovskii, Y. Strzhemechny, Aluminum Nitride Thermal Interface for Improving Heat Performance of High-Power Electronic Devices. 2019 XIth International Scientific and Practical Conference on Electronics and Information Technologies (ELIT), 253–256 (2019). https://doi.org/10.1109/ELIT.2019.8892341

I. Mathews, S. Lei, K. Nolan, G. Levaufre, A. Shen, G. Duan, B. Corbett, R. Enright, Towards AlN optical cladding layers for thermal management in hybrid lasers. Proc. SPIE 9520, Integrated Photonics: Materials, Devices, and Applications III, 95200J (2015). https://doi.org/10.1117/12.2178924

G. Lian, M. Jean, T. Chien, Application of AlN-Coated Heat Sink to Improve the Thermal Management of Light-Emitting Diode Assembles. Proceedings of the Thirteenth International Conference on Intelligent Information Hiding and Multimedia Signal Processing, Matsue, Shimane, Japan, Part II (2017).https://doi.org/10.1007/978-3-319-63859-1_28

J. Jaramillo-Fernandez, J. Ordonez-Miranda, E. Olliera, S. Volz, Tunable thermal conductivity of thin films of polycrystalline AlN by structural inhomogeneity and interfacial oxidation. Phys. Chem. Chem. Phys. 12, 7582–8284 (2015). https://doi.org/10.1039/c4cp05838k

S. Subramani, M. Devarajan, Performance of chemical vapor deposited boron-doped AlN thin film as thermal interface materials for 3-W LED: thermal and optical analysis. Acta Metall. Sin. (Engl. Lett.) (2017). https://doi.org/10.1007/s40195-017-0592-5

S. Subramani, M. Devarajan, Testing and analysis of boron-doped aluminum nitride thin-film-coated Al as thermal substrates in PCB fabrication for LED application. IEEE Trans. Elect. Dev. 63(12), 4839–4844 (2016)

N.H. Hashim, P. Anithambigai, D. Mutharasu, Thermal characterization of high power LED with ceramic particles filled thermal paste for effective heat dissipation. Microelectron. Reliab. 55, 383–388 (2015). https://doi.org/10.1016/j.microrel.2014.10.009

Acknowledgements

The first author would like to acknowledge Umaru Musa Yardua University, Katsina State and the TetFund Nigeria for research scholarship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical approval

On behalf of all the authors and the research institutions, there are not any conflicts of interest financially, non-financially, directly, or indirectly related to the research work, the authors or between the authors and their research institution.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

El-ladan, A.H., Subramani, S. Growth and performance analysis of BAlN alloy thin film on Al substrate as a heat spreader for effective thermal management applications on white-based high-power LED. Appl. Phys. A 127, 540 (2021). https://doi.org/10.1007/s00339-021-04617-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04617-3