Abstract

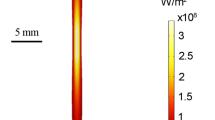

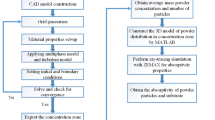

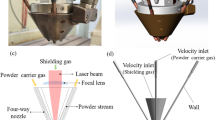

The present paper aims to develop an effective analytical solution for laser directed energy deposition through powder feeding (LDED-PF). Three heat source models are introduced and compared to analytically describe the transient temperature field in the process. These models are known as point (1D) heat source, circular (2D) heat source, and semi-spherical (3D) heat source. For the validation tests, single-track deposition of Ti-5Al-5 V-5Mo-3Cr powder on Ti-6Al-4 V substrate is conducted at different laser powers, scanning speeds, and powder feed rates. The temperature field is validated using the measurement of melt-pool/deposit geometry. In order to improve the model fidelity, the enhanced thermal diffusivity and heat source radius are calibrated in terms of linear functions. It is found that the 2D Gaussian heat source model, which is in agreement with the underlying physics of the process, establishes a better match between the predicted and experimental data. The developed model only needs the basic information from the LDED-PF setup and material thermal properties to predict the thermal history and melt-pool geometry at different processing parameters.

Similar content being viewed by others

References

E. Toyserkani, A. Khajepour, S. Corbin, Laser Cladding (CRC Press, Boca Raton, 2004)

Z. Tang, W. Liu, Y. Wang, K.M. Saleheen, Z. Liu, S. Peng, Z. Zhang, H. Zhang, Int. J. Adv. Manuf. Technol. 108, 3437 (2020)

H. Wang, W. Liu, Z. Tang, Y. Wang, X. Mei, K.M. Saleheen, Z. Wang, H. Zhang, Opt. Eng. 59, 1 (2020)

H.L. Wei, T. Mukherjee, W. Zhang, J.S. Zuback, G.L. Knapp, A. De, T. DebRoy, Prog. Mater. Sci. 116, 100703 (2020)

A.J. Pinkerton, J. Laser Appl. 27, S15001 (2015)

N. Tamanna, R. Crouch, S. Naher, Opt. Lasers Eng. 122, 151 (2019)

J. Ning, D.E. Sievers, H. Garmestani, S.Y. Liang, Appl. Phys. A 125, 496 (2019)

J. Li, Q. Wang, P. Michaleris, E.W. Reutzel, A.R. Nassar, J. Manuf. Sci. Eng. 139, 1 (2017)

M. Ansari, A. Martinez-Marchese, Y. Huang, E. Toyserkani, Materialia 12, 100710 (2020)

Y. Huang, M.B. Khamesee, E. Toyserkani, Addit. Manuf. 12, 90 (2016)

Y. Huang, M.B. Khamesee, E. Toyserkani, Opt. Laser Technol. 109, 584 (2019)

J. Goldak, A. Chakravarti, M. Bibby, Metall. Trans. B 15, 299 (1984)

S. Zhu, W. Chen, L. Ding, X. Zhan, and Q. Chen, Int. J. Adv. Manuf. Technol. 103, 3265 (2019)

H.S. Carslaw, J.C. Jaeger, Conduction of Heat in Solids, 2nd Edition (Oxford University Press, London, 1959)

A.J. Pinkerton, L. Li, J. Phys. D. Appl. Phys. 37, 1885 (2004)

Z. Zhang, Y. Huang, A. Rani Kasinathan, S. Imani Shahabad, U. Ali, Y. Mahmoodkhani, E. Toyserkani, Opt. Laser. Technol. 109, 297 (2019)

A. J. Pinkerton, R. Moat, K. Shah, L. Li, M. Preuss, and P. J. Withers, Int. Congr. Appl. Lasers Electro-Optics 2007, 1806 (2007)

Z. Liu, H.C. Zhang, S. Peng, H. Kim, D. Du, W. Cong, Addit. Manuf. 30, 100848 (2019)

C. Lampa, A.F.H. Kaplan, J. Powell, C. Magnusson, J. Phys. D. Appl. Phys. 30, 1293 (1997)

W. Zhang, C.-H. Kim, T. DebRoy, J. Appl. Phys. 95, 5220 (2004)

T. Lienert, T. Siewert, S. Babu, and V. Acoff, Editors, ASM Handbook, Volume 6A: Welding Fundamentals and Processes (ASM International, Materials Park, Ohio, 2011)

W.M. Steen, J. Mazumder, Laser Material Processing, 4th Edition (Springer, London, London, 2010)

D.B. Hann, J. Iammi, J. Folkes, J. Phys. D. Appl. Phys. 44, 445401 (2011)

R. Fabbro, J. Mater. Process. Technol. 264, 346 (2019)

W.E. King, H.D. Barth, V.M. Castillo, G.F. Gallegos, J.W. Gibbs, D.E. Hahn, C. Kamath, A.M. Rubenchik, J. Mater. Process. Technol. 214, 2915 (2014)

A.M. Rubenchik, W.E. King, S.S. Wu, J. Mater. Process. Technol. 257, 234 (2018)

V.A. Bykov, T.V. Kulikova, L.B. Vedmid, A.Y. Fishman, K.Y. Shunyaev, N.Y. Tarenkova, Phys. Met. Metallogr. 115, 705 (2014)

J. J. Valencia and P. N. Quested, in ASM Handbook: Metals Process Simulation, edited by D. U. Furrer and S. L. Semiatin, Vol. 22B (ASM International, 2010), pp. 18–32

Y. Huang, M. Ansari, H. Asgari, M.H. Farshidianfar, D. Sarker, M.B. Khamesee, E. Toyserkani, J. Mater. Process. Technol. 274, 116286 (2019)

A. Vasinonta, J.L. Beuth, M. Griffith, J. Manuf. Sci. Eng. 129, 101 (2007)

Acknowledgements

The authors would like to acknowledge the financial support of the Natural Sciences and Engineering Research Council of Canada (NSERC), and the Ontario Research Fund – Research Excellence (ORF-RE). The authors would like to acknowledge the encouragement and support from the members of the Multi-scale Additive Manufacturing lab (MSAM) at the University of Waterloo, especially Alexander Martinez-Marchese, Shahriar Imani Shahabad, and Osezua Ibhadode.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (AVI 25460 kb)

Supplementary file2 (AVI 23100 kb)

Rights and permissions

About this article

Cite this article

Ansari, M., Khamooshi, M., Huang, Y. et al. Analytical solutions for rapid prediction of transient temperature field in powder-fed laser directed energy deposition based on different heat source models. Appl. Phys. A 127, 445 (2021). https://doi.org/10.1007/s00339-021-04591-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04591-w