Abstract

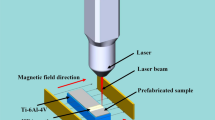

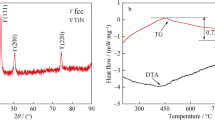

The directional array TiN-reinforced AlCoCrFeNiTi high-entropy alloy (HEA) coatings were successfully synthesized by magnetic field-assisted laser cladding on Ti-6Al-4V (TC4) alloy. The effect of magnetic induction intensity of AlCoCrFeNiTi HEA coatings was investigated methodically on thermodynamic calculation, microstructure characterization and corrosion resistance. The results show HEA coatings are mainly composed of body-centered cubic (BCC) solid solution phase, (Ni, Co)Ti2 intermetallic compound and TiN ceramic phase. With 1 T magnetic induction intensity assisted laser cladding, the microstructures of in situ TiN display a "cross" shape of the directional array. In 3.5 wt.% NaCl solution, the 1 T HEA coating could significantly decrease the corrosion rate compared with TC4 alloy.

Similar content being viewed by others

References

A.H. Ettefagh, C. Zeng, S. Guo, J. Raush, Addit. Manuf. 28, 252–258 (2019)

G. Chi, D. Yi, H. Liu, J. Mater. Res. Technol. 9, 1162–1174 (2020)

T.M. Yue, J.K. Yu, Z. Mei, H.C. Man, Mater. Lett. 52, 206–212 (2002)

M. Nabhani, R.S. Razavi, M. Barekat, Eng. Fail. Anal. 97, 234–241 (2019)

T.P.S. Sarao, H. Singh, H. Singh, J. Therm. Spray Techn. 27, 1388–1400 (2018)

A. Mthisi, A.P.I. Popoola, Int. J. Adv. Manuf. Tech. 100, 917–927 (2019)

L. Phume, A.P.I. Popoola, V.S. Aigbodion, S. Pityana, Int. J. Surf. Sci. Eng. 12, 23–39 (2018)

X. Jiao, J. Wang, C. Wang, Z. Gong, X. Pang, S.M. Xiong, Opt. Laser Eng. 110, 163–171 (2018)

M. Ma, Z. Wang, X. Zeng, Mat. Sci. Eng. A-Struct. 685, 265–273 (2017)

M.N. Fesharaki, R. Shoja-Razavi, H.A. Mansouri, H. Jamali, Surf. Coat. Tech. 353, 25–31 (2018)

S. Zhou, Y. Xu, B. Liao, Y. Sun, X. Dai, J. Yang, Z. Li, Opt. Laser Eng. 103, 8–16 (2018)

L.L. Zhai, C.Y. Ban, J.W. Zhang, Surf. Coat. Tech. 358, 531–538 (2019)

L. Zhai, C. Ban, J. Zhang, X. Yao, Mater. Lett. 243, 195–198 (2019)

Y. Li, X. Cui, G. Jin, Z. Cai, N. Tan, B. Lu, Y. Yang, Z. Gao, J. Liu, Surf. Coat. Tech. 325, 555–564 (2017)

J. Zhou, J. Xu, S. Huang, Z. Hu, X. Meng, X. Feng, Surf. Coat. Tech. 309, 212–219 (2017)

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Adv. Eng. Mater. 6, 299–303 (2004)

Y.Q. Jiang, J. Li, Y.F. Juan, Z.J. Lu, W.L. Jia, J. Alloy Compd. 775, 1–14 (2019)

F.Y. Shu, S. Liu, H.Y. Zhao, W.X. He, S.H. Sui, J. Zhang, B.S. Xu, J. Alloy Compd. 731, 662–666 (2018)

M. Zhang, X. Zhou, X. Yu, J. Li, Surf. Coat. Tech. 311, 321–329 (2017)

X. Li, Y. Feng, B. Liu, D. Yi, X. Yang, W. Zhang, P. Bai, J. Alloy Compd. 788, 485–494 (2019)

C. Ni, Y. Shi, J. Liu, G. Huang, Opt. Laser Technol. 105, 257–263 (2018)

H. Liu, J. Liu, P. Chen, H. Yang, Opt. Laser Technol. 118, 140–150 (2019)

G. Jin, Z. Cai, Y. Guan, X. Cui, Z. Liu, Y. Li, M. Dong, Appl. Surf. Sci. 445, 113–122 (2018)

X. Qiu, J. Alloy Compd. 735, 359–364 (2018)

G. Zhang, H. Liu, X. Tian, P. Chen, H. Yang, J. Hao, J. Mater. Eng. Perform. 29, 278–288 (2020)

X.W. Qiu, M.J. Wu, C.G. Liu, Y.P. Zhang, C.X. Huang, J. Alloy Compd. 708, 353–357 (2017)

Y. Shi, L. Collins, R. Feng, C. Zhang, N. Balke, P.K. Liaw, B. Yang, Corros. Sci. 133, 120–131 (2018)

Y. Shi, B. Yang, X. Xie, J. Brechtl, K.A. Dahmen, P.K. Liaw, Corros. Sci. 119, 33–45 (2017)

X.L. Shang, Z.J. Wang, Q.F. Wu, J.C. Wang, J.J. Li, J.K. Yu, Acta Metall. Sin-Engl. 32, 41–51 (2019)

H. Luo, Z. Li, A.M. Mingers, D. Raabe, Corros. Sci. 134, 131–139 (2018)

L. Wei, Y. Liu, Q. Li, Y.F. Cheng, Corros. Sci. 146, 44–57 (2019)

T. Fujieda, H. Shiratori, K. Kuwabara, M. Hirota, T. Kato, K. Yamanaka, Y. Koizumi, A. Chiba, S. Watanabe, Mater. Lett. 189, 148–151 (2017)

R.K. Mishra, P.P. Sahay, R.R. Shahi, J. Mater. Sci. 54, 4433–4443 (2019)

Y. Shi, L. Collins, N. Balke, P.K. Liaw, B. Yang, Appl. Surf. Sci. 439, 533–544 (2018)

Y. Cai, Y. Chen, S.M. Manladan, Z. Luo, F. Gao, L. Li, Mater. Design. 142, 124–137 (2018)

I. Kunce, M. Polanski, K. Karczewski, T. Plocinski, K.J. Kurzydlowski, J. Alloy Compd. 648, 751–758 (2015)

Z. Cai, G. Jin, X. Cui, Z. Liu, W. Zheng, Y. Li, L. Wang, Mater. Charact. 120, 229–233 (2016)

J.W. Yeh, Y.L. Chen, S.J. Lin, S.K. Chen, Mater. Sci. Forum 560, 1–9 (2007)

Y. Zhang, X. Yang, P.K. Liaw, Jom. 64, 830–838 (2012)

S. Guo, C.T. Liu, Prog Nat Sci-Mater. 21, 433–446 (2011)

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, P.K. Liaw, Adv. Eng. Mater. 10, 534–538 (2008)

S. Guo, Q. Hu, C. Ng, C.T. Liu, Intermetallics 41, 96–103 (2013)

A. Takeuchi, A. Inoue, Mater. Trans. 46(12), 2817–2829 (2005)

P.S. Herle, M.S. Hegde, N.Y. Vasathacharya, S. Philip, M.V.R. Rao, T. Sripathi, J. Solid State Chem. 134, 120–127 (1997)

W. Spengler, R. Kaiser, H. Bilz, Solid State Commun. 17(1), 19–22 (1975)

C. Yan, X. Cheng, Y. Zhang, D. Yin, C. Gong, L. Yu, Z. Zhang, J. Phys. Chem. C 116(49), 26006–26012 (2012)

J. Hao, J. Wang, X. Liu, W.J. Padilla, L. Zhou, M. Qiu, Appl. Phys. Lett. 96(25), 251104 (2010)

G. Liang, G. Jin, X.F. Cui, Z.Z. Qiu, J.Y. Wang, J. Mater. Eng. Perform. (2021). https://doi.org/10.1007/s11665-021-05680-w

K.H.J. Buschow, F.R.D. Boer, Physics of Magnetism and Magnetic Materials (Kluwer Academic/Plenum Publishers, New York, 2003).

Z. Ren, X. Li, H. Wang, K. Deng, Y. Zhuang, Mater. Lett. 58, 3405–3409 (2004)

Z. Qiu, R. Wang, J. Wu, Y. Zhang, Y. Qu, X. Wu, RSC Adv. 55, 44149–44159 (2015)

T. Li, O.J. Swanson, G.S. Frankel, A.Y. Gerard, P. Lu, J.E. Saal, J.R. Scully, Electrochim. Acta. 306, 71–84 (2019)

Q. Ye, K. Feng, Z. Li, F. Lu, R. Li, J. Huang, Y. Wu, Appl. Surf. Sci. 396, 1420–1426 (2017)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51975137, 51775127), the Fundamental Research Funds for Province Universities (No. Hkdcx201903), Heilongjiang Provincial Natural Science Foundation of China (No. LH2020E120), the China Postdoctoral Science Foundation (No. 2018M641809).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liang, G., Jin, G., Cui, X. et al. Designing AlCoCrFeNiTi high-entropy alloy with the directional array TiN by magnetic field-assisted laser cladding. Appl. Phys. A 127, 350 (2021). https://doi.org/10.1007/s00339-021-04500-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04500-1