Abstract

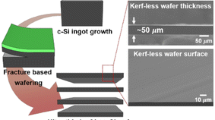

Laser dicing of ultrathin dies is promising and is gaining importance because of its cost and quality advantages over mechanical and plasma dicing. However, the effects of laser dicing on the mechanical strength and microstructure of ultrathin Si dies need to be further understood, especially when dicing through Si wafers with backside Cu layer. A critical phenomenon effecting the Si die sidewall strength after nanosecond laser dicing of Si wafers with backside Cu is the formation and separation of a SiO2 layer at the sidewall. The mechanisms behind the SiO2 layer formation and separation were studied in this work. Si wafer samples without and with backside Cu layer were prepared by dicing with nanosecond laser using standard production parameters. The microstructure and phases formed were investigated by energy dispersive spectroscopy and nanobeam diffraction in a transmission electron microscope. In die samples without backside Cu, the sidewall consists of a thin surface layer of amorphous Si, followed by a polycrystalline Si layer, and finally an epitaxial Si layer. In die samples with backside Cu, the sidewall microstructure was observed to be vastly different. At the upper region of the sidewall, a surface layer of polycrystalline Cu was found, followed by a polycrystalline Cu3Si layer, a SiO2 layer mixed with Cu3Si, and finally a thick SiO2 layer. The Cu3Si catalyzes the growth of the SiO2 through an oxidation step of the Cu3Si on the sidewall surface as well as at the SiO2/Si interface. In the lower region of the sidewall, the microstructure is similar to the upper region, but there is a separation of the SiO2 layer from the crystalline Si. The SiO2 undergoes a decomposition reaction at the SiO2/Si interface, releasing volatile SiO which causes microvoids to form and grow laterally at the interface. The growth and coalescence of the microvoids eventually lead to the separation of the SiO2 layer from the crystalline Si, leaving behind a clean and rough crystalline Si surface with a peak-to-peak roughness of 100–200 nm. In the areas where the SiO2 layer has separated from the Si die sidewall, the fracture strength of the sidewall is dependent on the material property and surface roughness of the crystalline Si, and not on the SiO2 layer. In the sidewall region near the die frontside, the SiO2 thickness is more than regions near the die backside, and no microvoiding and separation at the SiO2/Si interface were detected. This is hypothesized to be due to a higher O2 pressure at the upper region of the narrow dicing trench which is open to the atmosphere compared to the lower regions where there could be O2 deprivation and lower O2 pressure.

Similar content being viewed by others

References

M.R. Marks, Z. Hassan, K.Y. Cheong, Ultrathin wafer pre-assembly and assembly process technologies: A review. Crit. Rev. Solid State Mater. Sci. 40(5), 251–290 (2015)

M.R. Marks, Z. Hassan, K.Y. Cheong, Effect of nanosecond laser dicing on the mechanical strength and fracture mechanism of ultrathin Si dies with Cu stabilization layer. IEEE Trans. Compon. Packag. Manuf. Technol. 5(12), 1885–1897 (2015)

M.R. Marks, K.Y. Cheong, Z. Hassan, An improved three-point bending test method for the investigation of nanosecond laser dicing of ultrathin Si dies with Cu stabilization layer. Mater. Charact. 136, 29–40 (2018)

W.N. Sharpe Jr., J. Pulskamp, D.S. Gianola, C. Eberl, R.G. Polcawich, R.J. Thompson, Strain measurements of silicon dioxide microspecimens by digital imaging processing. Exp. Mech. 47(5), 649–658 (2007)

S.M. Hu, Critical stress in silicon brittle fracture, and effect of ion implantation and other surface treatments. J. Appl. Phys. 53(5), 3576–3580 (1982)

W. Marine, N.M. Bulgakova, L. Patrone, I. Ozerov, Insight into electronic mechanisms of nanosecond-laser ablation of silicon. J. Appl. Phys. 103, 094902(1)–094902(11) (2008)

F. Sanchez, J.L. Morenza, R. Aguiar, J.C. Delgado, M. Varela, Whiskerlike structure growth on silicon exposed to ArF excimer laser irradiation. Appl. Phys. Lett. 65(5), 620–622 (1996)

W.S. Lei, A. Kumar, R. Yalamanchili, Die singulation technologies for advanced packaging: A critical review. J. Vac. Sci. Technol. B 30(4), 040801(1)–040801(27) (2012)

J. Kaspar, A. Luft, Laser helical drilling of silicon wafers with ns to fs pulses: Scanning electron microscopy and transmission electron microscopy characterization of drilled through-holes. J. Laser Appl. 18(2), 85–92 (2006)

M. Hansen, K. Anderko, Constitution of Binary Alloys, 2nd edn. (McGraw-Hill, New York, 1958)

J.K. Solberg, The crystal structure of η-Cu3Si precipitates in silicon. Acta Crystallogr. A 34, 684–698 (1978)

C.Y. Wen, F. Spaepen, In situ electron microscopy of the phases of Cu3Si. Philos. Mag. A 87(35), 5581–5599 (2007)

M. Seibt, H. Hedemann, A.A. Istratov, F. Riedel, A. Sattler, W. Schroter, Structural and electrical properties of metal silicide precipitates in silicon. Phys. Status Solidi A 171, 301–310 (1999)

R.R. Chromik, W.K. Neils, E.J. Cotts, Thermodynamic and kinetic study of solid state reactions in the Cu–Si system. J. Appl. Phys. 86(8), 4273–4281 (1999)

R.E. Bouayadi, G. Regula, B. Pichaud, M. Lancin, C. Dubois, E. Ntsoenzok, Gettering of diffused Au and of Cu and Ni contamination in Si by cavities induced by high energy He implantation. Phys. Status Solidi B 222, 319–326 (2000)

M. Seibt, M. Griess, A.A. Istratov, H. Hedemann, A. Sattler, W. Schroter, Formation and properties of copper silicide precipitates in silicon. Phys. Status Solidi A 166, 171–182 (1998)

Inorganic Crystal Structure Database (ICSD), FIZ Karlsruhe - Leibniz Institute for Information Infrastructure, Germany

J.M.E. Harper, A. Charai, L. Stolt, F.M. d’Heurle, P.M. Fryer, Room temperature oxidation of silicon catalyzed by Cu3Si. Mater. Res. Soc. Symp. Proc. 187, 107–112 (1990)

G. Ottaviani, Metallurgical aspects of the formation of silicides. Thin Solid Films 140, 3–21 (1986)

C. Gelain, A. Cassuto, P. Le Goff, Kinetics and mechanism of low-pressure, high temperature oxidation of silicon - II. Oxid. Met. 3(2), 139–151 (1971)

E.A. Gulbransen, K.F. Andrew, F.A. Brassart, Oxidation of silicon at high temperatures and low pressure under flow conditions and the vapor pressure of silicon. J. Electrochem. Soc. 113(8), 834–837 (1966)

E.J. Nowak, J.M. Deckers, M. Boudart, Reaction probabilities for methane and oxygen on (111) silicon single-crystal surfaces. J. Catal. 11(2), 177–180 (1968)

J.J. Lander, J. Morrison, Low voltage electron diffraction study of the oxidation and reduction of silicon. J. Appl. Phys. 33(6), 2089–2092 (1962)

F.W. Smith, G. Ghidini, Reaction of oxygen with Si(111) and (100): Critical conditions for the growth of SiO2. J. Electrochem. Soc. Solid State Sci. Technol. 129(6), 1300–1306 (1982)

E.A. Gulbransen, S.A. Jansson, The high-temperature oxidation, reduction, and volatilization reactions of silicon and silicon carbide. Oxid. Met. 4(3), 181–201 (1972)

R. Tromp, G.W. Rubloff, P. Balk, F.K. LeGoues, E.J. van Loenen, High-temperature SiO2 decomposition at the SiO2/Si interface. Phys. Rev. Lett. 55(21), 2332–2335 (1985)

M. Liehr, J.E. Lewis, G.W. Rubloff, Kinetics of high-temperature thermal decomposition of SiO2 on Si. J. Vac. Sci. Technol. A 5(4), 1559–1562 (1987)

F. Leroy, T. Passanante, F. Cheynis, S. Curiotto, E.B. Bussmann, P. Muller, Catalytically enhanced thermal decomposition of chemically grown silicon oxide layers on Si(001). Appl. Phys. Lett. 108, 111601(1)–111601(4) (2016)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Marks, M.R., Yong, F.K., Cheong, K.Y. et al. Mechanism study of SiO2 layer formation and separation at the Si die sidewall during nanosecond laser dicing of ultrathin Si wafers with Cu backside layer. Appl. Phys. A 126, 138 (2020). https://doi.org/10.1007/s00339-020-3322-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-3322-1