Abstract

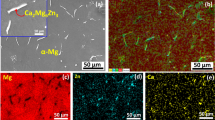

In this study, the microstructure, intermetallic phase, microhardness and wear resistance of unheated and heat-treated Mg-6Al-1Zn-xCu (x = 0, 0.5, 1, 2, and 4) alloys were investigated. The selective laser melted Mg-6Al-1Zn alloy that contained Cu had a typical continuous network structure that consisted of fine α-Mg grains and a eutectic phase. Uniformly distributed Mg2Cu was the main strengthening phase before heat treatment, and the analysis showed that the Mg2Cu was mainly present in the form of particles in the alloy. Most of the eutectic dissolved into the α-Mg matrix, and a granular Al2Cu phase was formed in the matrix after solution treatment. Al2Cu played a significant role in improving the high-temperature properties and wear resistance of the alloy. During the aging treatment, a helical phase (H phase) was formed that was rich in Cu and Al. Compared with those for the other Cu contents, the Mg-6Al-1Zn-2Cu alloy had the best wear resistance and antifriction properties.

Similar content being viewed by others

References

S.Q. Chen, X.P. Dong, R. Ma, L. Zhang, H. Wang, Z.T. Fan, Mater. Sci. Eng. A 551, 87 (2012)

N.C. Verissimo, C. Brito, C.R. Afonso, J.E. Spinelli, N. Cheung, A. Garcia, Mater. Chem. Phys. 204, 105 (2018)

N. Safari, M.R. Toroghinejad, M. Kharaziha, Mater. Chem. Phys. 237, 121838 (2019)

S. Hidetoshi, K. Akihito, K. Akira, Mater. Sci. Eng. A 732, 21 (2018)

Y. Motohiro, M. Naoki, H. Makoto, M. Mamoru, C. Yasumasa, Acta Mater. 83, 294 (2015)

D. Hu, Y. Wang, D.F. Zhang, L. Hao, J.J. Jiang, Z.H. Li, Y.T. Chen, Mater. Manuf. Process 30, 1298 (2015)

C.C. Ng, M.M. Savalani, M.L. Lau, H.C. Man, Appl. Surf. Sci. 257, 7447 (2011)

X.M. Niu, H.Y. Shen, J.Z. Fu, Mater. Lett. 221, 4 (2018)

B.C. Zhang, H.L. Liao, C. Coddet, Mater. Des. 34, 753 (2012)

K.W. Wei, X.Y. Zeng, Z.M. Wang, J.F. Deng, M.N. Liu, G. Huang, X.C. Yuan, Mater. Sci. Eng. A 756, 226 (2019)

C. Liu, M. Zhang, C.J. Chen, Mater. Sci. Eng. A 703, 359 (2017)

S. Liu, W.S. Yang, X. Shi, B. Li, S.C. Duan, H.J. Guo, J. Guo, J. Alloy. Compd. 808, 151160 (2019)

C.X. He, S.Z. Bin, P. Wu, C.D. Gao, P. Feng, Y.W. Yang, L. Liu, Y.Z. Zhou, M.C. Zhao, S. Yang, C.J. Shuai, Metals 7, 105 (2017)

K.W. Wei, M. Gao, Z.M. Wang, X.Y. Zeng, Mater. Sci. Eng. A 611, 212 (2014)

C.J. Shuai, B. Wang, S.Z. Bin, S.P. Peng, C.D. Gao, ACS Appl. Mater. Inter., 23464 (2020)

Q.C. Deng, Y.J. Wu, Y.H. Luo, N. Su, X.Y. Xue, Z.Y. Chang, Q.Y. Wu, Y.T. Xue, L.M. Peng, Mater. Charact. 165, 110377 (2020)

Y.W. Yang, C.F. Lu, S.P. Peng, L.D. Shen, D. Wang, F.W. Qi, C.J. Shuai, Virtual Phys. Prototy. 15, 278 (2020)

Y.W. Yang, C.X. He, E. Dianyu, W.J. Yang, F.W. Qi, D.Q. Xie, L.D. Shen, S.P. Peng, C.J. Shuai, Mater Des. 185, 108259 (2020)

D.F. Zhang, Z.H. Duan, H.J. Zhang, F.G. Qi, J. Chongqing Univ. 36, 79 (2013)

H.C. Pan, H. Fu, Y.P. Ren, Mater. Sci. Technol. 32, 1240 (2016)

Z.Y. You, Investigations on the influence of alloying elements on the microstructures and mechanical properties of high zinc magnesium alloys, Dissertation, Taiyuan University of Technology, 2012

X.C. Wang, C.J. Chen, M. Zhang, Rapid Prototyp. J. 26, 841 (2020)

H. Men, Z. Fan, Acta Mater. 59, 2704 (2011)

X.H. Hou, The mechanical research of solid state phase transformation and its effects on properties in Al–Cu–Mg alloy, Dissertation, Guangxi University, 2006

J. Kacher, C. Landon, B.L. Adams, D. Fullwood, Ultramicroscopy 109, 1148 (2009)

V. Raghavan, J. Phase Equilib. Diffus. 28, 174 (2007)

W. Tang, E.H. Han, Y.B. Xu, L. Liu, Acta Metall. Sin. 41, 1199 (2005)

T. Uesugi, K. Higashi, Comput. Mater. Sci. 67, 1 (2013)

D. Duly, J.P. Simon, Y. Brechet, Acta Metall. Mater. 43, 101 (1995)

Y.L. Xu, F. Gensch, Z. Ren, K.U. Kainer, N. Hort, Prog. Nat. Sci. 28, 724 (2018)

S. Zhou, Y.P. Sun, W.X. Wang, J.M. He, Heat Treat. Met. 44, 78 (2019)

A. Kumar, G.K. Meenashisundaram, V. Manakari, G. Parande, M. Gupta, J. Alloy. Compd. 695, 3612 (2017)

Acknowledgements

This research was funded by the State Key Laboratory of Advanced Processing and Recycling of Non-ferrous Metals, Lanzhou University of Technology [Grant Number SKLAB02014006]; the Suzhou Science and Technology Bureau [Grant Number SYG201642]; the open fund for Jiangsu Key Laboratory of Advanced Manufacturing Technology [Grant Number HGAMTL-1701]; and the Jiangsu province 333 talent project [Grant Number BRA2017098].

Author information

Authors and Affiliations

Contributions

XW: Experiment design, development and paper writing. CC: Theoretical suggestions, language modification. MZ: Experiment idea and suggestions, language modification.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, X., Chen, C. & Zhang, M. Effect of Cu addition and heat treatment on the microstructure and microwear of selective laser melted Mg–Al–Zn alloy. Appl. Phys. A 126, 714 (2020). https://doi.org/10.1007/s00339-020-03917-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-03917-4