Abstract

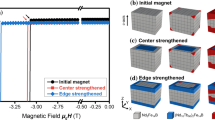

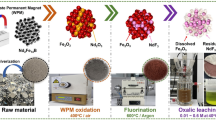

A large amount of wastes are generated during sintered NdFeB production, and recycling of those wastes shows huge economic and environmental benefits. In this work, grain boundary diffusion process is employed to enhance the coercivity of waste sintered (Nd,Ce,Gd)FeB magnets. Pr40Tb30Cu30 alloy is employed as the diffusion source. The coercivity of the waste magnet increased from 763 to 1287 kA/m without a consumption of remanence by optimized diffusion treatment. The maximum energy product and temperature stability of the magnets were also improved. The waste N30 magnet was successfully upgraded to N30M, close to N30H. It is found that that the shell/core structure with a Tb/Pr-rich shell and Nd/Ce/Gd-rich core was formed in the grain boundary diffused magnets, which is the main reason for the enhancement of coercivity and temperature stability. The detailed investigations clarified the distribution preference of different rare earth elements. Tb prefers entering into the main phase, while Pr tends to diffuse along the grain boundaries with large diffusion depth. The Nd, Ce and Gd elements also show different capacities of being replaced. These results suggest that the grain boundary diffusion process can be used as an efficient recycling method for those waste NdFeB magnets which were not seriously oxidized.

Similar content being viewed by others

References

O. Gutfleisch, M.A. Willard, E. Bruck, C.H. Chen, S.G. Sankar, J.P. Liu, Adv. Mater. 23, 821 (2011)

S. Sugimoto, J. Phys. D: Appl. Phys. 44, 064001 (2011)

M. Zakotnik, C.O. Tudor, Waste Manag. 44, 48 (2015)

A. Golev, M. Scott, P.D. Erskine, S.H. Ali, G.R. Ballantyne, Resour. Pol. 41, 52 (2014)

Kataoka Y, Ono T, Tsubota M, Kitagawa J, AIP Adv. 5, 117212 (2015)

S. Shirayama, T.H. Okabe, Metall. Mater. Trans. B 49, 1067 (2018)

Y. Chen, H. Wang, Y. Pei, J. Ren, J. Wang, ACS Sustain. Chem. Eng. 3, 3167 (2015)

V. Innocenzi, F. Vegliò, J. Power Sour. 211, 184 (2012)

M. Itoh, K. Miura, K-i Machida, J. Alloys Compd. 477, 484 (2009)

T. Uda, Mater. Trans. 43, 55 (2002)

M. Zakotnik, I.R. Harris, A.J. Williams, J. Alloys Compd. 450, 525 (2008)

R.S. Sheridan, R. Sillitoe, M. Zakotnik, I.R. Harris, A.J. Williams, J. Magn. Magn. Mater. 324, 63 (2012)

Y. Zhang, M. Liu, S. Sun, X. Yin, Y. Yin, J. Guo, W. Liu, D. Zhang, M. Yue, J. Magn. Magn. Mater. 475, 465 (2019)

H. Sepehri-Amin, T. Ohkubo, M. Zakotnik, D. Prosperi, P. Afiuny, C.O. Tudor, K. Hono, J. Alloys Compd. 694, 175 (2017)

M. Itoh, M. Masuda, S. Suzuki, K-i Machida, J. Alloys Compd. 374, 393 (2004)

X. Li, M. Yue, M. Zakotnik, W. Liu, D. Zhang, T. Zuo, J. Rare Earths 33, 736 (2015)

M. Itoh, K. Nishiyama, F. Shogano, T. Murota, K. Yamamoto, M. Sasada, K-i Machida, J. Alloys Compd. 451, 507 (2008)

H. Nakamura, K. Hirota, M. Shimao, T. Minowa, M. Honshima, IEEE Trans. Magn. 41, 3844 (2005)

J. Song, S. Guo, G. Ding, K. Chen, R. Chen, D. Lee, A. Yan, J. Magn. Magn. Mater. 469, 613 (2019)

K.C. Lu, X.Q. Bao, G.X. Chen, X. Mu, X.J. Zhang, X.K. Lv, Y. Ding, X.X. Gao, J. Magn. Magn. Mater. 477, 237 (2019)

J. Li, L. Liu, H. Sepehri-Amin, X. Tang, T. Ohkubo, N. Sakuma, T. Shoji, A. Kato, T. Schrefl, K. Hono, Acta Mater. 161, 171 (2018)

J. Di, G. Ding, X. Tang, X. Yang, S. Guo, R. Chen, A. Yan, Scripta Mater. 155, 50 (2018)

J.R. Xiao, Z.W. Liu, H.S. Lou, H.X. Zhan, Acta Phys. Sin. 67, 9 (2018)

S. Hirosawa, Y. Matsuura, H. Yamamoto, S. Fujimura, M. Sagawa, H. Yamauchi, J. Appl. Phys. 59, 873 (1986)

Y. Zhang, T. Ma, J. Jin, J. Li, C. Wu, B. Shen, M. Yan, Acta Mater. 128, 22 (2017)

X. Tang, H. Sepehri-Amin, T. Ohkubo, M. Yano, M. Ito, A. Kato, N. Sakuma, T. Shoji, T. Schrefl, K. Hono, Acta Mater. 144, 884 (2018)

T. Ma, M. Yan, K. Wu, B. Wu, X. Liu, X. Wang, Z. Qian, C. Wu, W. Xia, Acta Mater. 142, 18 (2018)

J.F. Herbst, Rev. Mod. Phys. 63, 819 (1991)

H. Zeng, Z. Liu, W. Li, J. Zhang, L. Zhao, X. Zhong, H. Yu, B. Guo, J. Magn. Magn. Mater. 471, 97 (2019)

S. Kim, D.-S. Ko, H.-S. Lee, D. Kim, J.W. Roh, W. Lee, J. Alloys Compd. 780, 574 (2019)

W. Li, Q. Zhang, Q. Zhu, S. Xiao, C. Xu, L. Yang, B. Zheng, S. Mao, Z. Song, Scripta Mater. 163, 40 (2019)

Acknowledgements

This work was partly supported by the National Natural Science Foundation of China (Grant no. 51774146) and the Guangdong Key Laboratory of Rare Earth Development and Applications (Grant no. XTKY-201801).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., He, J., Yu, H. et al. Restoring and enhancing the coercivity of waste sintered (Nd,Ce,Gd)FeB magnets by direct Pr–Tb–Cu grain boundary diffusion. Appl. Phys. A 126, 657 (2020). https://doi.org/10.1007/s00339-020-03857-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-03857-z