Abstract

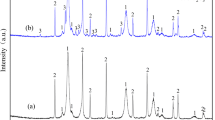

Al2O3-ZrO2 composite coatings were fabricated by plasma spraying Al2O3-ZrO2 composite powders with and without Y2O3 addition to learn the influence of Y2O3 on high temperature stability of the coating. The two coatings both underwent phase transformation in the process of heat treatment. Specifically, XRD results showed that in the Al2O3-ZrO2-Y2O3 coating, Y3Al5O12 (YAG) phase existed after heating at 800 °C, and γ-Al2O3 all transformed to α-Al2O3 after heating at 1200 °C, so the composition of the coating was t-ZrO2, α-Al2O3 and YAG after heating at 1200 °C, while in the Al2O3-ZrO2 coating, the final coating consisted of t-ZrO2 and α-Al2O3 beacuse γ-Al2O3 all transformed to α-Al2O3 after heating at 1200 °C. The amorphous phase in the two as-sprayed coatings had been crystallized completely after heat treatment at 1200 °C. Heat treatment can reduce the porosity and improve the hardness of the two coatings, and YAG phase can also improve the hardness. The coating with TC4 substrate had better thermal shock resistance than it with Q235 steel substrate. The thermal shock resistance of the Al2O3-ZrO2-Y2O3 coating was better than that of the Al2O3-ZrO2 coating at same condition. NiCrAlY bonding layer can improve thermal shock resistance of the coating.

Similar content being viewed by others

References

D. Zhao, S.Q. Xia, Y.G. Wang et al., Appl. Phys. A. 126, 1–9 (2020)

H.M. Hawthorne, L.C. Erickson, D. Ross. Wear. 203, 709–714 (1997)

Y. Yang, Y. Wang, W. Tian et al., J. Alloys Compd. 622, 929 (2015)

S.J. Dong, B. Song, H.L. Lia et al., Appl. Phys. A. 118, 283–290 (2015)

R. Westergård, N. Axén, U. Wiklund et al., Wear. 246, 12–19 (2000)

I. Ahmad, S. Ahmed, T. Subhani et al., Curr. Appl. Phys. 16, 1649–1658 (2016)

K.B. Sachidananda, K. Mahesha, A.J. Dey, Ceram. Int. 44, 158–163 (2018)

S. Chen, J. Xiang, J. Huang et al., Appl. Surf. Sci. 340, 173–181 (2015)

W.R. Chen, X. Wu, D. Dudzinski et al., Surf. Coat. Technol. 200, 5863–5868 (2006)

P. Fauchais, M. Vardelle, A. Vardelle et al., Plasma Chem. Plasma Process. 16, S99–S125 (1995)

Y. Wang, Y. Bai, K. Liu et al., Appl. Surf. Sci. 363, 101–112 (2016)

P. Wei, Z. Wei, S. Li et al., Appl. Surf. Sci. 321, 538–547 (2014)

S. Lee, H. Choi, S. Shin et al., Curr. Appl. Phys. 14, 552–557 (2014)

C.G. Aneziris, S. Dudczig, N. Gerlach et al., Adv. Eng. Mater. 12, 478–485 (2010)

F. Tarasi, M. Medraj, A. Dolatabadi et al., J. Adv. Funct. Mater. 21, 4143–4151 (2011)

G.D. West, J.M. Perkins, M.H. Lewis, J. Eur. Ceram. Soc. 27(4), 1913–1918 (2007)

K. Yang, J. Rong, J.W. Feng et al., J. Eur. Ceram Soc. 36, 4261–4267 (2016)

M. Wang, L.L. Shaw, Surf. Coat. Technol. 202, 34–44 (2007)

A. Keyvani, J. Alloys Compd. 623, 229–237 (2015)

R. Younes, M.A. Bradai, A. Sadeddine et al., Chin J Nonferrous Met. 26, 1345–1352 (2016)

A.L. Vasiliev, N.P. Padture, Acta Mater. 54, 4921–4928 (2006)

P. Ramaswamy, S. Seetharamu, K.B.R. Varma et al., Sci. Technol. 57, 81–89 (1997)

X.Q. Zhao, Y.L. An, J.M. Chen et al., Wear 265, 1642–1648 (2008)

F. Tarasi, M. Medraj, A. Dolatabadi et al., J. Eur. Ceram. Soc. 31, 2903–2913 (2011)

X.M. Song, T. Suhonen, T. Varis, J. Therm SprayTechn 23, 1302–1311 (2014)

H.J. Kim, Y.J. Kim, J. Mater. Sci. 34(29), 3 (1999)

J. Suffner, H. Sieger, H. Hahn et al., J. Mater. Sci. Eng, A. 506, 180–186 (2009)

D. Chen, E.H. Jordan, M. Gell et al., J. Am. Ceram. Soc. 91, 359–365 (2008)

A. Mcdonald, S. Chandra, M. Lamontagne et al., Therm. Spray Technol. 15, 708–716 (2006)

J.O. Berghaus, J.G. Legoux, C. Moreau et al., Therm. Spray Technol. 17, 91–104 (2008)

X. Zhou, V. Shukla, W.R. Cannon, J. Am. Ceram. Soc. 6, 1415–1420 (2003)

X Zhang, Y. W. Wang, W. W. Wang et al., J. Therm. Spray. Tech. https://doi.org/10.1007/s11666-020-01043-4

M.J. Liu, Z. Wang, X.W. Luan, J. Alloys Compd. 656, 929–935 (2016)

L. Liang, X.N. Li, Y.G. Wei, Int. J. Appl. Ceram. Technol. 12, 1096–1102 (2015)

C. Wang, Y. Xia, R.Q. Qiao et al., Int. J. Appl. Ceram. Technol. 16, 1373–1380 (2019)

Q. Zhang, C.J. Li, Y. Li, Therm. Spray Technol. 17, 838–845 (2008)

Y. Wang, W. Tian, Y. Yang, Surf. Coat. Technol. 201, 7746–7754 (2007)

Acknowledgements

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (51672067, 51541208, 51102074), the Natural Science Foundation of Hebei Province (E2018202034, E2015202070), Foundation for Talent Training Project in Hebei Province (A2016002026) and Foundation for the top talents in Universities in Hebei Province (SLRC2017027).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, WW., Wang, XL., Sun, XW. et al. Microstructure and properties of Al2O3-ZrO2-Y2O3 coatings during high temperature and thermal shock resistance. Appl. Phys. A 126, 639 (2020). https://doi.org/10.1007/s00339-020-03819-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-03819-5