Abstract

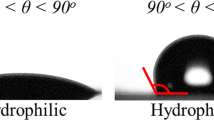

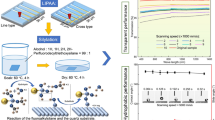

This study describes a simple method to fabricate a transparent superhydrophobic soda-lime glass surface. The method uses only laser-beam machining and heat treatment, without the application of a chemical coating. The resulting surface exhibited superhydrophobicity at a contact angle (CA) greater than 170° and a sliding angle (SA) less than 10°. In addition, relatively acceptable transmittance (> 50%) in visible light was observed. The superhydrophobic surface and superior transmittance were shown at relatively high laser powers (0.4 and 0.5 W), with a relatively large step size (300 and 350 µm). At a laser power of 0.2 W, the superhydrophobicity of the surface decreased. When the step size was increased from 150 to 350 µm with a reduced laser power (0.2 and 0.3 W), the CA decreased slightly and the SA increased from 5° to 60°. CA and SA can, therefore, be controlled with process parameters.

Similar content being viewed by others

References

S. Nishimoto, B. Bhushan, RSC Adv. 3, 671 (2013)

J. Chen, Z. Luo, Q. Fan, J. Lv, J. Wang, Small 10, 4693 (2014)

M.H.M.A. Shibraen, H. Yagoub, X. Zhang, J. Xu, S. Yang, Appl. Surf. Sci. 370, 1 (2016)

A.H.A. Lutey, L. Gemini, L. Romoli, G. Lazzini, F. Fuso, M. Faucon, R. Kling, Sci. Rep. 8, 1 (2018)

D.M. Chun, C.V. Ngo, K.M. Lee, CIRP Ann. Manuf. Technol. 65, 519 (2016)

Y. Tuo, H. Zhang, W. Rong, S. Jiang, W. Chen, X. Liu, Langmuir 35, 11016 (2019)

C. Dong, Y. Gu, M. Zhong, L. Li, K. Sezer, M. Ma, W. Liu, J. Mater. Process. Technol. 211, 1234 (2011)

C.V. Ngo, D.M. Chun, Adv. Eng. Mater. 20, 1 (2018)

C.-V. Ngo, D.-M. Chun, Appl. Surf. Sci. 435, 974 (2018)

T.H. Dinh, C.V. Ngo, D.M. Chun, Nanomaterials 8, 766 (2018)

Y. Lin, J. Han, M. Cai, W. Liu, X. Luo, H. Zhang, M. Zhong, J. Mater. Chem. A 6, 9049 (2018)

C.V. Ngo, D.M. Chun, CIRP Ann. 67, 571 (2018)

A. Riveiro, A.L.B. Maçon, J. del Val, R. Comesaña, J. Pou, Front. Phys. 6, 16 (2018)

D.M. Chun, G. Davaasuren, C.V. Ngo, C.S. Kim, G.Y. Lee, S.H. Ahn, CIRP Ann. Manuf. Technol. 63, 525 (2014)

X. Chen, J. Wen, J. Zhou, Z. Zhang, D. Yan, H. Wang, W. Xie, R. Zhan, N. Xu, J. Chen, J. She, H. Chen, S. Deng, J. Opt. 20, 024012 (2018)

P. Dimitrakellis, A. Travlos, V.P. Psycharis, E. Gogolides, Plasma Process. Polym. 14, 1 (2017)

S. Sutha, S. Suresh, B. Raj, K.R. Ravi, Sol. Energy Mater. Sol. Cells 165, 128 (2017)

L. Zhang, C.H. Xue, M. Cao, M.M. Zhang, M. Li, J.Z. Ma, Chem. Eng. J. 320, 244 (2017)

S. Zhao, J. Zhao, M. Wen, M. Yao, F. Wang, F. Huang, Q. Zhang, Y.B. Cheng, J. Zhong, Langmuir 34, 11316 (2018)

B. Wang, Y. Hua, Y. Ye, R. Chen, Z. Li, Appl. Surf. Sci. 426, 957 (2017)

L.B. Boinovich, A.G. Domantovskiy, A.M. Emelyanenko, A.S. Pashinin, A.A. Ionin, S.I. Kudryashov, P.N. Saltuganov, A.C.S. Appl, Mater. Interfaces 6, 2080 (2014)

K.J. Bachus, L. Mats, H.W. Choi, G.T.T. Gibson, R.D. Oleschuk, A.C.S. Appl, Mater. Interfaces 9, 7629 (2017)

S. Moradi, N. Hadjesfandiari, S.F. Toosi, J.N. Kizhakkedathu, S.G. Hatzikiriakos, A.C.S. Appl, Mater. Interfaces 8, 17631 (2016)

S. Takeda, K. Yamamoto, Y. Hayasaka, K. Matsumoto, J. Non. Cryst. Solids 249, 41 (1999)

E. Ueda, P.A. Levkin, Adv. Mater. 25, 1234 (2013)

Acknowledgements

This research was support by a National Research Foundation of Korea (NRF) Grant (NRF-2018R1A2B6004012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Dinh, TH., Ngo, CV. & Chun, DM. Direct laser patterning for transparent superhydrophobic glass surfaces without any chemical coatings. Appl. Phys. A 126, 462 (2020). https://doi.org/10.1007/s00339-020-03653-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-03653-9