Abstract

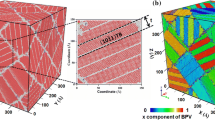

To investigate the \(\{10\bar{1}2\}\) tension twin effects on the dynamic recrystallization structure evolution in magnesium alloys, the compression deformation of a magnesium polycrystal containing an initial \(\{10\bar{1}2\}\) tension twin under different loading directions was simulated by molecular dynamics method. The results showed that the dynamic recrystallization phenomena only occurred when loading normal to twin boundary. By tracking atoms’ motion, it was found that the twin dynamic recrystallization microstructure evolution could be divided into two steps. Step one: basal partial dislocations nucleated near twin boundary, leading to large area of stacking faults; Step two: due to the accumulation of strain energy, non-basal slip systems nucleated in the stacking faults region, promoting the stacking faults to recover to hexagonal close-packed structure and forming the new grains. When loading parallel to twin boundary, the twin boundary migration dominated the deformation process, which released the strain energy and inhibited the nucleation of dynamic recrystallization.

Similar content being viewed by others

References

J. Hirsch, T. Al-Samman, Superior light metals by texture engineering: optimized aluminum and magnesium alloys for automotive applications. Acta Mater. 61, 818–843 (2013)

M. Easton, A. Beer, M. Barnett, C. Davies, G. Dunlop, Y. Durandet, S. Blacket, T. Hilditch, P. Beggs, Magnesium alloy applications in automotive structures. JOM 60, 57–62 (2008)

A. Luo, Magnesium: current and potential automotive applications. JOM 54, 42–48 (2002)

B. Verlinden, Severe plastic deformation of metals, Association of Metallurgical Engineers Serbia and Montenegr (2005)

A. Galiyev, R. Kaibyshev, G. Gottstein, Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60. Acta Mater. 49, 1199–1207 (2001)

Z. Yu, H. Choo, Influence of twinning on the grain refinement during high-temperature deformation in a magnesium alloy. Scripta Mater. 64, 434–437 (2011)

AYu. Volkov, O.V. Antonova, B.I. Kamenetskii, I.V. Klyukin, D.A. Komkova, B.D. Antonov, Production, structure, texture, and mechanical properties of severely deformed magnesium. Phys. Metals Metallogr. 117, 518–528 (2016)

R. Alizadeh, R. Mahmudi, A.H.W. Ngan, Y. Huang, T.G. Langdon, Superplasticity of a nano-grained Mg–Gd–Y–Zr alloy processed by high-pressure torsion. Mater. Sci. Eng. A 651, 786–794 (2016)

F. Akbaripanah, F. Fereshteh-Saniee, R. Mahmudi, H.K. Kim, Microstructural homogeneity, texture, tensile and shear behavior of AM60 magnesium alloy produced by extrusion and equal channel angular pressing. Mater. Des. 43, 31–39 (2013)

H. Hu, Y. Liu, D. Zhang, Z. Ou, The influences of extrusion-shear process on microstructures evolution and mechanical properties of AZ31 magnesium alloy. J. Alloys Compd. 695, 1088–1095 (2017)

X. Li, W. Xia, H. Yan, J. Chen, B. Su, M. Song, Z. Li, Y. Li, Dynamic recrystallization behaviors of high mg alloyed al-mg alloy during high strain rate rolling deformation. Mater. Sci. Eng. A 753, 59–69 (2019)

J. Jiang, M. Song, H. Yan, C. Yang, S. Ni, Deformation induced dynamic recrystallization and precipitation strengthening in an Mg–Zn–Mn alloy processed by high strain rate rolling. Mater. Char. 121, 135–138 (2016)

M.R. Barnett, Twinning and the ductility of magnesium alloys: Part I:“Tension” twins. Mater. Sci. Eng. A 464, 1–7 (2007)

M.R. Barnett, Twinning and the ductility of magnesium alloys: Part II:“Contraction” twins. Mater. Sci. Eng. A 464, 8–16 (2007)

P. Klimanek, A. Pötzsch, Microstructure evolution under compressive plastic deformation of magnesium at different temperatures and strain rates. Mater. Sci. Eng. A 324, 145–150 (2002)

D. Yin, K. Zhang, F. Wang, W. Han, Warm deformation behavior of hot-rolled AZ31 Mg alloy. Mater. Sci. Eng. A 392, 320–325 (2005)

M.H. Yoo, I.K. Lee, Deformation twinning in hcp metals and alloys[J]. Philos. Mag. A 63, 987–1000 (1991)

H. El Kadiri, C.D. Barrett, J. Wang, C.N. Tomé, Why are \(\{10\bar{1}2\}\) twins profuse in magnesium? Acta Materialia 85, 354–361 (2015)

F. Guo, D. Zhang, X. Fan, J. Li, L. Jiang, F. Pan, Microstructure, texture and mechanical properties evolution of pre-twinning Mg alloys sheets during large strain hot rolling. Mater. Sci. Eng. A 655, 92–99 (2016)

I.L. Valery, M.R. Arunabha, L.P. Dean, Multiple twinning and variant-variant transformations in martensite: phase-field approach. Phys. Rev. B 88, 054113 (2013)

I.L. Valery, M.R. Arunabha, Multiphase phase field theory for temperature- and stress-induced phase transformations. Phys. Rev. B 91, 174109 (2015)

E. Popova, Y. Staraselski, A. Brahme, R.K. Mishra, K. Inal, Coupled crystal plasticity-Probabilistic cellular automata approach to model dynamic recrystallization in magnesium alloys. Int. J. Plastic. 66, 85–102 (2015)

E. Popova, A.P. Brahme, Y. Staraselski, S.R. Agnew, R.K. Mishra, K. Inal, Effect of extension \(\{10\bar{1}2\}\) twins on texture evolution at elevated temperature deformation accompanied by dynamic recrystallization. Mater. Des. 96, 446–457 (2016)

D.C. Rapaport, D.C.R. Rapaport, The art of molecular dynamics simulation (Cambridge University Press, Cambridge, 2004)

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995)

D. Sun, M.I. Mendelev, C.A. Becker, K. Kudin, T. Haxhimali, M. Asta, J.J. Hoyt, A. Karma, D.J. Srolovitz, Crystal-melt interfacial free energies in hcp metals: a molecular dynamics study of Mg. Phys. Rev. B 73, 024116 (2006)

A. Stukowski, Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 18, 015012 (2009)

D. Faken, H. Jónsson, Systematic analysis of local atomic structure combined with 3D computer graphics. Comput. Mater. Sci. 2, 279–286 (1994)

W.B. Hutchinson, M.R. Barnett, Effective values of critical resolved shear stress for slip in polycrystalline magnesium and other hcp metals. Scripta Mater. 63, 737–740 (2010)

G.D. Sim, G. Kim, S. Lavenstein, M. Hamza, H. Fan, J.A. EI-Awady, Anomalous hardening in magnesium driven by a size-dependent transition in deformation modes. Acta Mater. 144, 11–20 (2018)

A. Serra, D.J. Bacon, R.C. Pond, Comment on “atomic shuffling dominated mechanism for deformation twinning in magnesium”. Phys. Rev. Lett. 104, 029603 (2010)

C.D. Barrett, H. El Kadiri, The roles of grain boundary dislocations and disclinations in the nucleation of \(\{10\bar{1}2\}\) twinning. Acta Mater. 63, 1–15 (2014)

Q. Zu, X. Tang, S. Xu, Y. Guo, Atomistic study of nucleation and migration of the basal/prismatic interfaces in Mg single crystals. Acta Mater. 130, 310–318 (2017)

B. Li, E. Ma, Atomic shuffling dominated mechanism for deformation twinning in magnesium. Phys. Rev. Lett. 103, 035503 (2009)

A. Ostapovets, R. Gröger, Twinning disconnections and basal-prismatic twin boundary in magnesium. Model. Simul. Mater. Sci. Eng. 22, 025015 (2014)

C.D. Barrett, H. El Kadiri, Impact of deformation faceting on \(\{10\bar{1}2\}\), \(\{10\bar{1}1\}\) and \(\{10\bar{1}3\}\) embryonic twin nucleation in hexagonal close-packed metals. Acta Mater. 70, 137–161 (2014)

Y. Chen, L. Jin, J. Dong, Z.Y. Zhang, F.H. Wang, Twinning effects on the hot deformation behavior of AZ31 Mg alloy[J]. Mater. Char. 118, 363–369 (2016)

D. Guan, W.M. Rainforth, L. Ma, B. Wynne, J.H. Gao, Twin recrystallization mechanisms and exceptional contribution to texture evolution during annealing in a magnesium alloy. Acta Mater. 126, 132–144 (2017)

S.W. Xu, S. Kamado, N. Matsumoto, T. Honma, Y. Kojima, Recrystallization mechanism of as-cast AZ91 magnesium alloy during hot compressive deformation. Mater. Sci. Eng. A 527, 52–60 (2009)

I. Basu, T. Al-Samman, Competitive twinning behavior in magnesium and its impact on recrystallization and texture formation. Mater. Sci. Eng. A 707, 232–244 (2017)

L. Yan, L. Xiao, Deformation behavior of a coarse-grained Mg-8Al-1.5Ca-0.2Sr magnesium alloy at elevated temperatures. J. Mater. Eng. Perform. 27, 905–914 (2018)

R.D. Doherty, D.A. Hughes, F.J. Humpheys, J.J. Jonas, D.J. Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen, A.D. Rollett, Current issues in recrystallization: a review. Mater. Sci. Eng. A 238, 219–274 (1997)

Acknowledgements

The work was supported by the National Natural Science Foundation of China [Grant No. 10772169], the Fundamental Research Funds for the Central Universities [WK 2480000002], and the Strategic Priority Research Program of Chinese Academy of Science [Grant No. XDB22040502].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, S., Wang, Y., Wang, Y. et al. The effect of tension twin on the dynamic recrystallization behavior in polycrystal magnesium by atomistic simulation. Appl. Phys. A 126, 65 (2020). https://doi.org/10.1007/s00339-019-3255-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-019-3255-8