Abstract

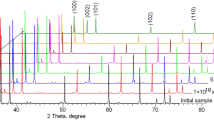

The work is devoted to the study of the use of pulsed beams with a high current density to create a highly defective layer in nitride ceramics to increase the radiation resistance to helium swelling. Scanning electron microscopy, X-ray diffraction, and atomic force microscopy were used as research methods. It was established that irradiation with a pulsed beam leads to a change in the morphology of the surface layer, not exceeding 0.5–0.7 μm thickness with the formation of a large number of grain boundaries and defects resulting from the impact of a high-density ion pulse over a nanosecond time interval. Using the X-ray diffraction method, it was found that irradiation with a pulsed beam leads to a slight change in stresses and dislocations in the structure, which creates additional obstacles to helium swelling. During tests of the radiation resistance of nitride ceramics to helium swelling, it was found that for modified samples a decrease in helium swelling and He2+ concentration in the structure of the surface layer was observed, while for unmodified samples, helium bubbles were formed, whose size was from 70 to 200 nm. The presence of these helium inclusions is due to the low solubility of He2+ in the structure, as well as the high mobility of He2+ and the ability to agglomerate with the formation of gas cavities in the structure.

Similar content being viewed by others

References

J. Serp et al., The molten salt reactor (MSR) in generation IV: overview and perspectives. Prog. Nucl. Energy 77, 308–319 (2014)

L.K. Mansur et al., Materials needs for fusion, Generation IV fission reactors and spallation neutron sources–similarities and differences. J. Nucl. Mater. 329, 166–172 (2004)

D. Seyferth, G.H. Wiseman, High-yield synthesis of Si3N4/SiC ceramic materials by pyrolysis of a novel polyorganosilazane. J. Am. Ceram. Soc. 67(7), C-132 (1984)

T.A. Parthasarathy et al., Modeling environmentally induced property degradation of SiC/BN/SiC ceramic matrix composites. J. Am. Ceram. Soc. 101(3), 973–997 (2018)

S. Hu et al., Oxyacetylene torch testing and microstructural characterization of a Cr2AlC ceramic. J. Alloys Compd. 740, 77–81 (2018)

X. Jin et al., Effects of water vapor on the crystallization and microstructure manipulation of MgO ceramic fibers. Ceram. Int. 44(5), 5257–5265 (2018)

D.I. Shlimas et al., Structure and corrosion properties of thin TiO2 films obtained by magnetron sputtering. Vacuum 164, 224–232 (2019)

A.V. Trukhanov et al., Control of structural parameters and thermal conductivity of BeO ceramics using heavy ion irradiation and post-radiation annealing. Ceram. Int. 45(12), 15412–15416 (2019)

K. Dukenbayev et al., Study of the effect of irradiation with Fe7+ ions on the structural properties of thin TiO2 foils. Mater. Res. Express 6(4), 046309 (2019)

Y. Onoda et al., Thermally stimulated luminescence properties of Eu-doped AlN ceramic. Optik 181, 50–56 (2019)

Y. Lan et al., Fabrication and characterization of single-phase a-axis AlN ceramic films. Ceram. Int. 44(7), 8257–8262 (2018)

V.P. Srinivasan, P.K. Palani, L. Selvarajan, Experimental investigation on electrical discharge machining of ceramic composites (Si3N4–TiN) using RSM. Int. J. Comput. Mater. Sci. Surf. Eng. 7(2), 104–115 (2018)

D. Wang et al., Microstructure design and preparation of Al2O3/TiC/TiN micro–nano-composite ceramic tool materials based on properties prediction with finite element method. Ceram. Int. 44(5), 5093–5101 (2018)

F. Shayesteh et al., Influence of TiN dopant on microstructure of TiB2 ceramic sintered by spark plasma. Ceram. Int. 45(5), 5306–5311 (2019)

T.S. Ferreira, F.M.S. Carvalho, C.C. Guedes-Silva, Densification and microstructure of Si3N4–TiN ceramic composites. Cerâmica 65, 87–91 (2019)

Z. Yan et al., Friction and wear behavior of TiN films against ceramic and steel balls. Tribol. Int. 124, 61–69 (2018)

H. Jiang et al., Effects of Y2O3–LaF3 on the low temperature sintering and thermal conductivity of AlN ceramics. Microelectron. Int. 36(1), 22–25 (2019)

A.L. Kozlovskii et al., Radiation defects in aluminum nitride-based ceramics. High Energy Chem. 53(1), 71–75 (2019)

Z. Luo et al., Synthesis and properties of AlN/MAS/Si3N4 ternary glass–ceramic composites with in-situ grown rod-like β-Si3N4 crystals. Ceram. Int. 44(2), 1875–1880 (2018)

D. Huang et al., High thermal conductive AlN substrate for heat dissipation in high-power LEDs. Ceram. Int. 45(1), 1412–1415 (2019)

M. Obradović et al., Effects of helium ion irradiation on bubble formation in AlN/TiN multilayered system. Thin Solid Films 591, 164–168 (2015)

L.L. Snead, S.J. Zinkle, D.P. White, Thermal conductivity degradation of ceramic materials due to low temperature, low dose neutron irradiation. J. Nucl. Mater. 340(2–3), 187–202 (2005)

D.J. Tallman et al., Effect of neutron irradiation on select MAX phases. Acta Mater. 85, 132–143 (2015)

T. Yano et al., Neutron irradiation effects on isotope tailored aluminum nitride ceramics by a fast reactor up to 2 × l026 n/m2. J. Nucl. Mater. 329, 1471–1475 (2004)

T. Shikama et al., Gas nuclear transmutation effects in aluminum nitride. Fusion Sci. Technol. 44(2), 495–499 (2003)

V.V. Uglov et al., Size effect in AlN/SiN multilayered films irradiated with helium and argon ions. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact Mater Atoms 435, 228–235 (2018)

P. Song et al., Irradiation resistance properties studies on helium ions irradiated MAX phase Ti3AlC2. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact Mater Atoms 326, 332–336 (2014)

Y. Pramono, M. Imai, T. Yano, Helium release and physical property change of neutron-irradiated α-SiC containing B4C of different 10B concentrations. J Nucl Sci Technol 40(7), 531–536 (2003)

W.J. Weber et al., Radiation effects in crystalline ceramics for the immobilization of high-level nuclear waste and plutonium. J. Mater. Res. 13(6), 1434–1484 (1998)

K. Katahira et al., ELID grinding characteristics and surface modifying effects of aluminum nitride (AlN) ceramics. Int. J. Mach. Tools Manuf. 45(7–8), 891–896 (2005)

P. Motamedi, K. Cadien, Structural and optical characterization of low-temperature ALD crystalline AlN. J. Cryst. Growth 421, 45–52 (2015)

M. Milosavljević et al., A comparison of Ar ion implantation and swift heavy Xe ion irradiation effects on immiscible AlN/TiN multilayered nanostructures. Mater. Chem. Phys. 133(2–3), 884–892 (2012)

M. Barlak et al., Ion beam modification of ceramic component prior to formation of AlN–Cu joints by direct bonding process. Surf. Coat. Technol. 201(19–20), 8317–8321 (2007)

A.R. Olszyna et al., Surface modification of Al2O3–Cr ceramic by non-isothermal N2 plasma treatment at atmospheric pressure. Plasma Process. Polym. 4(S1), S507–S511 (2007)

C. Dong et al., Surface treatment by high current pulsed electron beam. Surf. Coat. Technol. 163, 620–624 (2003)

D.I. Proskurovsky et al., Physical foundations for surface treatment of materials with low energy, high current electron beams. Surf. Coat. Technol. 125(1–3), 49–56 (2000)

S. Hao et al., Surface modification of steels and magnesium alloy by high current pulsed electron beam. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact Mater Atoms 240(3), 646–652 (2005)

K. Zhang et al., Improved pitting corrosion resistance of AISI 316L stainless steel treated by high current pulsed electron beam. Surf. Coat. Technol. 201(3–4), 1393–1400 (2006)

K.M. Zhang et al., Improved in vitro corrosion resistance of a NiTi alloy by high current pulsed electron beam treatment. Surf. Coat. Technol. 201(6), 3096–3102 (2006)

J. Zou et al., Selective surface purification via crater eruption under pulsed electron beam irradiation. Appl. Phys. Lett. 89(4), 041913 (2006)

J.X. Zou et al., Mechanisms of hardening, wear and corrosion improvement of 316 L stainless steel by low energy high current pulsed electron beam surface treatment. Thin Solid Films 519(4), 1404–1415 (2010)

Y. Qin et al., Temperature–stress fields and related phenomena induced by a high current pulsed electron beam. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact Mater Atoms 225(4), 544–554 (2004)

R. Kobayashi et al., Evaluation of grain-boundary conduction of dense AlN–SiC solid solution by scanning nonlinear dielectric microscopy. J. Am. Ceram. Soc. 93(12), 4026–4029 (2010)

A. Kozlovskiy et al., Dynamics of changes in structural properties of AlN ceramics after Xe+22 ion irradiation. Vacuum 155, 412–422 (2018)

A. Kozlovskiy et al., Investigation of the influence of irradiation with Fe+7 ions on structural properties of AlN ceramics. Mater. Res. Express 5(6), 065502 (2018)

K. Dukenbayev et al., Investigation of radiation resistance of AlN ceramics. Vacuum 159, 144–151 (2019)

A. Kozlovskiy et al., Effect of swift heavy ions irradiation on AlN ceramics properties. Ceram. Int. 44(16), 19787–19793 (2018)

A. Kozlovskiy, Influence of irradiation temperature on properties change of AlN ceramics. Vacuum 158, 93–100 (2018)

A. Kozlovskiy et al., Influence of He-ion irradiation of ceramic AlN. Vacuum 163, 45–51 (2019)

T. Gladkikh et al., Changes in optical and structural properties of AlN after irradiation with C2+ ions of 40 keV. Vacuum 161, 103–110 (2019)

A.K. Zak et al., X-ray analysis of ZnO nanoparticles by Williamson–Hall and size–strain plot methods. Solid State Sci. 13(1), 251–256 (2011)

M. Zdorovets et al., Defect formation in AlN after irradiation with He2+ ions. Ceram Int 45(7), 8130–8137 (2019)

J.-C. Nappé et al., Effect of swift heavy ion irradiations in polycrystalline aluminum nitride. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact Mater Atoms 269(2), 100–104 (2011)

T. Gladkikh et al., Radiation resistance of AlN ceramics as a result of irradiation with low-energy C2+ ions. Mater. Charact. 150, 88–97 (2019)

A. Kozlovskiy et al., Optical and structural properties of AlN ceramics irradiated with heavy ions. Opt. Mater. 91, 130–137 (2019)

Acknowledgements

This research was funded under NU ORAU project (Nazarbayev University) “Investigation of high-intensity pulsed ion beam neutralization by volumetric plasma”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kaikanov, M., Kozlovskiy, A.L., Abduvalov, A. et al. Study of using pulsed beams to increase the radiation resistance of nitride ceramics to helium swelling. Appl. Phys. A 125, 555 (2019). https://doi.org/10.1007/s00339-019-2857-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-019-2857-5