Abstract

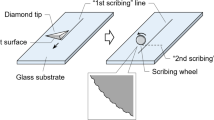

In the silicon dicing processes, the laser induced thermal-crack propagation (LITP) has been reported about its superiority over traditional dicing methods in aspect of crack surface quality and mechanical properties. However, this process may cause deviation of its propagation path especially under the condition of asymmetric linear cutting. Aiming to solve the path-deviation problem, a method of pre-crack on the surface of the silicon wafer has been proposed. A mathematical model which consists absorption of laser, heat transfer, generation of thermal stress, and crack initiation and propagation, has been established. Numerical simulation in the LITP of silicon wafer with respect to two pre-crack modes: pre-crack on the end and pre-crack on the surface were conducted to study the high-quality crack propagation mechanism. Unbiased crack propagation was found in the simulation of pre-crack on the surface process and the mechanism of it was revealed through the analysis of the tensile stress distribution. It was found that the three-dimensional shape of the tensile stress at the front of the crack tip would result in an uncertain propagation in conventional LITP of pre-crack on the end. Conversely, the slice shape of the tensile stress would induce a certain propagation direction that was along the plane of the pre-crack in the simulation of pre-crack on the surface. The experimental results verified the unbiased propagation mode and showed good crack surface quality.

Similar content being viewed by others

References

M.R. Marks, Z. Hassan, K.Y. Cheong, Ultrathin wafer pre-assembly and assembly process technologies: a review. C R C Crit. Rev. Solid State Sci. 40(5), 251–290 (2015)

Z.J. Pei, G.R. Fisher, J. Liu, Grinding of silicon wafers: a review from historical perspectives. Int. J. Mach. Tools Manuf 48(12), 1297–1307 (2008)

S.Y. Luo, Z.W. Wang, Studies of chipping mechanisms for dicing silicon wafers. Int. J. Adv. Manuf. Technol. 35(11–12), 1206–1218 (2008)

N. Sudani, K. Venkatakrishnan, B. Tan, Laser singulation of thin wafer: die strength and surface roughness analysis of 80 μm silicon dice. Opt. Lasers Eng. 47(7), 850–854 (2009)

R.M. Lumley, Controlled separation of brittle materials using a laser. Am. Ceram. Soc. Bull. 48, 850–854 (1969)

O. Haupt, F. Siegel, A. Schoonderbeek et al., Laser dicing of silicon: comparison of ablation mechanisms with a novel technology of thermally induced stress. J. Laser Micro Nanoeng. 3(3), 135–140 (2008)

O. Haupt, V. Schuetz, A. Schoonderbeek et al., High quality laser cleaving process for mono-and polycrystalline silicon. Proc. SPIE 7202, 1–11 (2009)

T. Ueda, K. Yamada, K. Oiso et al., thermal stress cleaving of brittle materials by laser beam. CIRP Ann. – Manuf. Technol. 51(1), 149–152 (2002)

C. Zhao, H. Zhang, Y. Wang, Semiconductor laser asymmetry cutting glass with laser induced thermal-crack propagation. Opt. Lasers Eng. 63, 43–52 (2014)

C. Zhao, H. Zhang, L. Yang et al., Dual laser beam revising the separation path technology of laser induced thermal-crack propagation for asymmetric linear cutting glass. Int. J. Mach. Tools Manuf 106, 43–55 (2016)

K. Yamada, S. Nishioka, A. Hosokawa et al., Cleaving process of brittle materials with pulsed YAG laser: thermal stress analysis in cleaving process of silicon wafer. J. Jpn. Soc. Precis. Eng. 69(1), 120–124 (2003)

S.V. Shalupaev, A.N. Serdyukov, G.S. Mityurich et al., Modeling of mechanical influence of double-beam laser on single-crystalline silicon. Arch. Metall. Mater. 58(4), 1381–1385 (2013)

A.M. Saman, T. Furumoto, A. Hosokawa et al., Thermal stress cleaving of Si-wafer: investigation of fracture initiation during laser beam irradiation. Adv. Mater. Res. 1101(4), 412–418 (2015)

Y. Cai, L. Yang, H. Zhang et al., Laser cutting silicon-glass double layer wafer with laser induced thermal-crack propagation. Opt. Lasers Eng. 82, 173–185 (2016)

Y. Cai, M. Wang, H. Zhang et al., Laser cutting sandwich structure glass–silicon–glass wafer with laser induced thermal–crack propagation. Opt. Laser Technol. 93(93), 49–59 (2017)

B. Lawn, Fracture of Brittle Solids, 2nd edn. (Cambridge University Press, Cambridge, 1993)

Acknowledgements

National Key R&D Program of China (Grant No. 2018YFB1107600).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, X., Yang, L., Wang, M. et al. The unbiased propagation mechanism in laser cutting silicon wafer with laser induced thermal-crack propagation. Appl. Phys. A 125, 479 (2019). https://doi.org/10.1007/s00339-019-2763-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-019-2763-x