Abstract

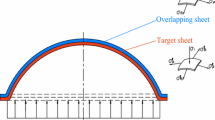

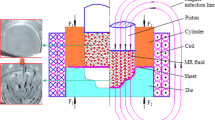

In the field of sheet forming, how to improve its performance is one of long-term goals. It is also an important basis for determining the quality and reliability of sheet forming. In this paper, the influence of overlapping sheet conditions on bulging behavior of Al1060 sheet using force-transmitting medium has been studied. That is, it uses a “soft-and-hard” double-side pressure loading method. The results show that the bulging behavior and forming ability of the aluminum sheet may be changed by adding an overlapping sheet. Compared with the condition without overlapping sheet, when the thickness of the overlapping sheet is 0.5 mm, the maximum thinning rate reduces from 43.95 to 38.16%. It improves the deformation uniformity of the entire target aluminum sheet, and the forming performance also increases with it. Compared with the situation of 1 mm overlapping sheet thickness under the same condition, the uniformities of the wall thickness distribution and the forming properties of the target aluminum sheet with an overlapping sheet thickness of 0.5 mm are significantly better and it reveals the causes. It also establishes that a theoretical model of the warp stress varies with angle, and provides scientific guidance for the improvement of light alloy forming performance and the expanding of the implementation about thin-sheet magnetic media pressure technology.

Similar content being viewed by others

References

S.J. Yuan, R. Zhang, W.W. Zhang, Integral hot gas pressure forming of an AA2219 aluminum alloy ellipsoidal shell. JOM 69, 1–6 (2017)

Z.H.A.N.G. Zhi-chao, X.U. Yong-chao, Y.U.A.N. Shi-jian, Analysis of thickness variation of reverse deep drawing of preformed 5A06 aluminum alloy cup under different temperatures. Int. J. Adv. Manuf. Technol. 86, 521–529 (2016)

D.Y. Chen, Y. Xu, S.H. Zhang, Z.J. Zhao, A. El-Aty Ali, Y. Ma, J.M. Li, Evaluation of numerical and experimental investigations on the hybrid sheet hydroforming process to produce a novel high-capacity engine oil pan. Int. J. Adv. Manuf. Technol. 97(9–12), 3625–3636 (2018)

H.-K. Kim, Seok Kwan Hong. FEM-based optimum design of multi-stage deep drawing process of molybdenum sheet. J. Mater. Process. Tech. 184(1), 354–362 (2006)

W.D. Li, B. Meng, C. Wang, M. Wan, L. Xu, Effect of pre-forming and pressure path on deformation behavior in multi-pass hydrodynamic deep drawing process. Int. J. Mech. Sci. 121, 171–180 (2017)

L.H. LANG, Y.M. WANG, Y.S. XIE, X.Y. YANG, Y.Q. XU, Pre-bulging effect during sheet hydroforming process of aluminum alloy box with unequal height and flat bottom. Trans. Nonferr. Metals Soc. China 22, s302–s308 (2012)

M.O.R.I. Ken-ichiro, Smart hot stamping of ultra-high strength steel parts. Trans. Nonferr. Metals Soc. China 22(S2), 496–503 (2012)

W. Liu, H.S. Liu, Z.W. Xing et al., Effect of tool temperature and punch speed on hot stamping of ultra high strength steel. Trans. Nonferr. Metals Soc. China 22, s534–s541 (2012)

H.C. Tseng, J.C. Hung, C. Hung et al., Experimental and numerical analysis of titanium/aluminum clad metal sheets in sheet hydroforming. Int. J. Adv. Manuf. Technol. 54(1–4), 93–111 (2011)

Y. Wang, L.H. Lang, T.J. Gao et al., Flow property of AA2B06 sheet using overlapping elliptical bulge test. Trans. Nonferr. Metals Soc. China 26(8), 2179–2187 (2016)

R. Zhang, L. Lang, R. Zafar et al., Investigation into thinning and spring back of multilayer metal forming using hydro-mechanical deep drawing (HMDD) for lightweight parts. Int. J. Adv. Manuf. Technol. 82(5–8), 817–826 (2016)

B. Teng, Hu Lan, L. Gang, Y. Shi-Jian, Wrinkling behavior of hydro bending of carbon steel/Al-alloy bi-layered tubes. Trans. Nonferr. Metals Soc. China 22, 560–565 (2012)

T.J. Gao, Y. Liu, P. Chen et al., Analysis of bulging process of aluminum alloy by overlapping sheet metal and its formability. Trans. Nonferr. Metals Soc. China 25(4), 1050–1055 (2015)

C.C. Jin, F. Li, Z.P. Bao, Study on deep drawing of 304 stainless steel rectangular case with magnetic medium. Int. J. Adv. Manufac. Technol. 94(1–4), 1525–1531 (2017)

F. Li, F.J. Zhou, M.N. Wang et al., Experimental studies on flexible forming of sheet metals assisted by magnetic force transfer medium. JOM 68(8), 1–7 (2016)

Acknowledgements

This work was financially supported by State Key Lab of Advanced Welding and Joining, Harbin Institute of Technology (AWJ-19M01). The authors would like to take this opportunity to express their sincere appreciation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bao, Z.P., Li, F., Li, C. et al. Enhancement on deformation uniformity of the target sheet by bulging process with magnetic medium and overlapping sheet. Appl. Phys. A 125, 116 (2019). https://doi.org/10.1007/s00339-019-2412-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-019-2412-4