Abstract

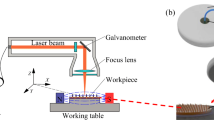

To develop a bioelectrode with excellent electrical performance, laser micromachining was proposed to fabricate a metal dry bioelectrode with a non-uniform surface microstructure. By controlling the scanning path, scanning times, and output power, metal dry bioelectrodes with different types of surface microstructure distribution (uniform and non-uniform) were obtained. Compared with traditional Ag/AgCl wet electrode, the influence of the surface microstructure distribution on the impedance and electromyographic properties of metal dry bioelectrodes was investigated. Results show that the surface microstructure distribution has little influence on the impedance properties of the bioelectrode within the testing time and frequency domains. However, the electromyographic properties of metal dry bioelectrodes with uniform and non-uniform surface microstructures were better than that of conventional Ag/AgCl wet electrodes. The strongest electromyographic signal was obtained using a metal dry bioelectrode with non-uniform surface microstructure.

Similar content being viewed by others

References

Y.M. Chi, T.P. Jung, G. Cauwenberghs, Dry-contact and noncontact biopotential electrodes: methodological review. IEEE Rev. Biomed. Eng. 3, 106–119 (2010)

P. Salvo, R. Raedt, E. Carrette, D. Schaubroeck, J. Vanfleteren, L. Cardon, A 3D printed dry electrode for ECG/EEG recording. Sens. Actuator A Phys. 174, 96–102 (2012)

A. Troiano, L. Mesin, F. Naddeo, E. Sosso, G. Camarota, R. Merletti, Assessment of force and fatigue in isometric contractions of upper trapezius muscle by perceived exertion scale and EMG signal. Gait Posture. 28, S37–S38 (2008)

B.C. Kang, T.J. Ha, Wearable carbon nanotube based dry-electrodes for electrophysiological sensors. in International Conference on Flexible and Printes Electronics. South Korea. SEP 04–07, 2017

J.M. Jung, D.Y. Cha, D.S. Kim, J.Y. Hee, K.S. Choi, J.M. Choi, S.P. Chang, Development of PDMS-based flexible dry type SEMGelectrodes by micromachining technologies. Appl. Phys. A. 116, 1395–1401 (2014)

P. Laferriere, E.D. Lemaire, A.D.C. Chan, Surface electromyographic signals using dry electrodes. IEEE Trans. Instrum. Meas. 60, 3259–3268 (2011)

T. Linz, L. Gourmelon, G. Langereis, Contactless EMG Sensors Embroidered onto Textile 4th International Workshop on Wearable and Implantable Body Sensor Networks (BSN 2007) (Springer, Berlin, 2007), pp. 29–34

B.G. Lapatki, J.P. Van Dijk, I.E. Jonas, M.J. Z warts, D.F. Stegeman, A thin, flexible multielectrode grid for high-density surface EMG. J. Appl. Physiol. 96, 327–336 (2004)

K. Nagata, K. Ando, S. Nakano, H. Nakajima, M. Yamada, K. Magatani, Development of the human interface equipment based on surface EMG employing channel selection method. in 28th Annual International Conference of the IEEE Engineering in Medicine and Biology Society. New York, USA, 2006

K. Nagata, T. Nakano, K. Magatani, M. Yamada, Estimation of muscle strength during motion recognition using multichannel surface EMG signals. in 30th Annual International Conference of the IEEE Engineering in Medicine and Biology Society. Vancouver, Canada, 2008

W. Zhou, R. Song, X. Pan, X.L. Peng, Y.J. Qi, J.H. Peng, K.S. Hui, K.N. Hui, Fabrication and impedance measurement of novel metal dry bioelectrode. Sens. Actuator A Phys. 201, 127–133 (2013)

S.W. Lee, H.S. Shin, C.N. Chu, Fabrication of micro-pin array with high aspect ratio on stainless steel using nanosecond laser beam machining. Appl. Surf. Sci. 264, 653–663 (2013)

J.R. Ho, C.P. Grigoropoulos, J.A.C. Humphrey, Computational study of heat transfer and gas dynamics in the pulsed laser evaporation of metals. J. Appl. Phys. 78, 4696–4709 (1995)

H.E. Qing, W.U. Bao, C. Peng, The detection analysis method of surface EMG signal and its application. Foreign Med. Biomed. Eng. 23, 299–303 (2000)

D. Graiielaflavia, R. Flavia, G. Emilia, Surface electromyography in biomechanics: applications and signal analysis aspects. J. Phys. Educ. Sport. 25, 67–77 (2009)

T. Yamaguchi, S. Mikami, K. Okada, Validity of a newly developed ultraminiature cordless EMG measurement system. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. 104, 22–27 (2007)

C.C. Auchincloss, L. McLean, The reliability of surface EMG recorded from the pelvic floor muscles. J. Neurosci. Methods 182, 85–96 (2009)

A. Reffad, K. Mebarkia, T.M.M. Vieira, C. Disselhorst-Klug, Effect of contraction force and knee joint angle on the spatial representation of soleus activity using high-density surface EMG. Biomed. Eng. Biomed. Tech. 59, 399–411 (2014)

H.L. Peng, J.Q. Liu, H.C. Tian, B.D. Xu, Z. Yun, B. Yang, X. Chen, C.S. Yang, Flexible dry electrode based on carbon nanotube/polymer hybrid micropillars for biopotential recording. Sens. Actuators Phys. 235, 48–56 (2015)

A. Phinyomark, F. Quaine, S. Charbonnier, S. Christine, T. Franck, L. Yann, EMG feature evaluation for improving myoelectric pattern recognition robustness. Expert Syst. Appl. 40, 4832–4840 (2013)

S. Myllymaa, S. Pirinen, K. Myllymaa, M. Suvanto, T.A. Pakkanen, Improving electrochemical performance of flexible thin film electrodes with micropillar array structures. Meas. Sci. Technol. 23, 1–11 (2012)

W. Zhou, W.S. Ling, W. Liu, Y.J. Peng, J.H. Peng, Laser direct micromilling of copper-based bioelectrode with surface microstructure array. Opt. Lasers Eng. 73, 7–15 (2015)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Project no. 51475397), Science and technology Plan Project of Xiamen City (Project no. 3502Z20173024) and the Natural Science Foundation of Fujian Province of China (No. 2017J06015). In addition, the supports from the Open Fund of Beijing Advanced Innovation Center for Intelligent Robots and Systems (No. 2016IRS21) are also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, W., Li, Y., Liu, S. et al. Impedance and electromyographic properties of metal dry bioelectrode with non-uniform surface microstructure. Appl. Phys. A 124, 754 (2018). https://doi.org/10.1007/s00339-018-2187-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-2187-z