Abstract

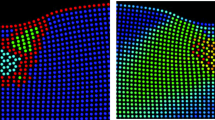

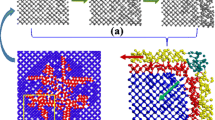

Here, we present nanoindentation on single-crystal copper via large-scale molecular dynamics (MD) simulation to provide clarification on load drop and the correlated hardness drop during plastic deformation of a workpiece placed beneath an indenter. According to the clear criterion of contact between the atoms in the workpiece and in the indenter, the contact area between the indenter and workpiece is calculated, and the general hardness and the spatiotemporal distribution of the dislocations around the indenter are also obtained. In the elastic stage, MD simulation results are in good agreement with the Hertzian solution. During the indentation, dislocations are dominated by the glissile Shockley partial dislocations (SPDs), while the proportion of other sessile dislocations is low and grows sluggishly. The density of the dislocations that aggregated around the indenter remained at approximately \(10^{17}\,\text {m}^{-2}\) during the indentation process. Dislocations adhered to the indenter concentrate in the volume of the hemisphere whose radius is three times of the radius of plastic zone. Load drop takes place after hardness drop which marks the abrupt and massive growth of the glissile SPDs. The more and more dense state of atoms around the indenter caused by dislocation behaviors result in the increase of hardness, while the avalanche of glissile SPDs leads to the following drop, which occurs repeatedly and causes a sawtooth pattern of the load-depth and hardness-depth curves over the entire indentation process.

Similar content being viewed by others

References

Y.Y. Lim, M.M. Chaudhri, Philos. Mag. A. 79(12), 2979 (1999)

W. Lee, Y. Chen, Int. J. Plast. 26(10), 1527 (2010)

T. Fu, X. Peng, Y. Zhao, C. Feng, C. Huang, Q. Li, Z. Wang, Appl. Phys. A 122(2), 67 (2016)

T. Fu, X. Peng, X. Chen, S. Weng, N. Hu, Q. Li, Z. Wang, Sci. Rep. 6(1), 35665 (2016)

Y. Chiu, A. Ngan, Acta Mater. 50(10), 2677 (2002)

N. Zaafarani, D. Raabe, F. Roters, S. Zaefferer, Acta Mater. 56(1), 31 (2008)

E. Demir, D. Raabe, N. Zaafarani, S. Zaefferer, Acta Mater. 57(2), 559 (2009)

E. Lilleodden, J. Zimmerman, S. Foiles, W. Nix, J. Mech. Phys. Solids. 51(5), 901 (2003)

J. Lian, J. Wang, Y.Y. Kim, J. Greer, J. Mech. Phys. Solids. 57(5), 812 (2009)

Y. Lee, J.Y. Park, S.Y. Kim, S. Jun, S. Im, Mech. Mater. 37(10), 1035 (2005)

D. Mordehai, M. Kazakevich, D.J. Srolovitz, E. Rabkin, Acta Mater. 59(6), 2309 (2011)

T. Remington, C. Ruestes, E. Bringa, B. Remington, C. Lu, B. Kad, M. Meyers, Acta Mater. 78, 378 (2014)

R. Kositski, D. Mordehai, Acta Mater. 90, 370 (2015)

R. Kositski, O. Kovalenko, S.W. Lee, J.R. Greer, E. Rabkin, D. Mordehai, Sci. Rep. 6, 25966 (2016)

W.D. Nix, H. Gao, J. Mech. Phys. Solids. 46(3), 411 (1998)

M.F. Ashby, Philos. Mag. 21(170), 399 (1970)

C. Ruestes, A. Stukowski, Y. Tang, D. Tramontina, P. Erhart, B. Remington, H. Urbassek, M. Meyers, E. Bringa, Mater. Sci. Eng. A 613, 390 (2014)

A. Stukowski, K. Albe, Model. Simul. Mater. Sci. Eng. 18(8), 085001 (2010)

Y. Gao, C.J. Ruestes, D.R. Tramontina, H.M. Urbassek, J. Mech. Phys. Solids 75, 58 (2015)

G.Z. Voyiadjis, M. Yaghoobi, Mater. Sci. Eng. A 634, 20 (2015)

Y. Mishin, M.J. Mehl, D.A. Papaconstantopoulos, A.F. Voter, J.D. Kress, Phys. Rev. B 63(22), 224106 (2001)

K. Maekawa, A. Itoh, Wear 188(1), 115 (1995)

S. Plimpton, J. Comput. Phys. 117(1), 1 (1995)

A. Stukowski, Model. Simul. Mater. Sci. Eng. 18(1), 015012 (2010)

M. Talaei, N. Nouri, S. Ziaei-Rad, Mech. Mater. 102, 97 (2016)

G. Ziegenhain, H.M. Urbassek, A. Hartmaier, J. Appl. Phys. 107(6), 061807 (2010)

D. Saraev, R.E. Miller, Model. Simul. Mater. Sci. Eng. 13(7), 1089 (2005)

D. Saraev, R.E. Miller, Acta Mater. 54(1), 33 (2006)

J. Hua, A. Hartmaier, Model. Simul. Mater. Sci. Eng. 18(4), 045007 (2010)

U. Landman, W.D. Luedtke, N.A. Burnham, R.J. Colton, Science 248(4954), 454 (1990)

K.L. Johnson, Contact Mechanics (Cambridge University Press, New York, 1985)

J. Alcalá, R. Dalmau, O. Franke, M. Biener, J. Biener, A. Hodge, Phys. Rev. Lett. 109(7), 075502 (2012)

T. Tsuru, Y. Shibutani, Phys. Rev. B 75, 035415 (2007)

H. Liang, C. Woo, H. Huang, A. Ngan, T. Yu, Comput. Model. Eng. Sci. 6(1), 105 (2004)

S. Goel, A. Kovalchenko, A. Stukowski, G. Cross, Acta Mater. 105, 464 (2016)

Q. Liu, L. Deng, X. Wang, Mater. Sci. Eng. A 676, 182 (2016)

R.M.J. Cotterill, Phys. Lett. A 60(1), 61 (1977)

W.M. Mook, C. Niederberger, M. Bechelany, L. Philippe, J. Michler, Nanotechnology 21(5), 055701 (2010)

J.P. Hirth, J. Lothe, Thoery of Dislocation (Wiley, New York, 1982)

K. Durst, B. Backes, M. Gken, Scr. Mater. 52(11), 1093 (2005)

J. Swadener, E. George, G. Pharr, J. Mech. Phys. Solids 50(4), 681 (2002)

D. Wu, T. Nieh, Mater. Sci. Eng. A 609, 110 (2014)

Y. Kamimura, K. Edagawa, S. Takeuchi, Acta Mater. 61(1), 294 (2013)

S. Chandra, M. Samal, V. Chavan, S. Raghunathan, Int. J. Plast. 101, 188 (2018)

F.C. Nix, D. MacNair, Phys. Rev. 60(8), 597 (1941)

Acknowledgements

L. Deng, Q.T. Liu, X.Y. Wang, and J.J. Li acknowledge the financial support from National Science Foundation for Distinguished Young Scholars of China through Grant No. 51725504 and National Natural Science Foundation of China through Grant Nos. 51675200 and 51435007. Numerical simulations presented here were carried out using the high-performance computing experimental testbed at the National Supercomputing Centre in Shenzhen (Shenzhen Cloud Computing Centre) (see http://www.nsccsz.gov.cn/).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, L., Liu, Q., Wang, X. et al. Load drop and hardness drop during nanoindentation on single-crystal copper investigated by molecular dynamics. Appl. Phys. A 124, 743 (2018). https://doi.org/10.1007/s00339-018-2146-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-2146-8