Abstract

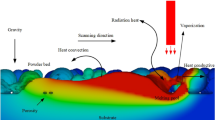

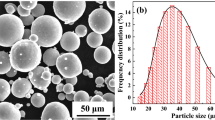

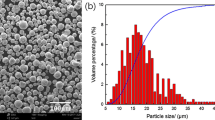

Selective laser melting (SLM) is one of the most promising additive manufacturing (AM) processes. Each single track in SLM may affect the forming defects and the resultant relative density of final SLM parts. A three-dimensional randomly distributed powder bed model of Ti6Al4V was established to study the forming process of single track. The numerical model is verified by experimental tests. The numerical results show that—the typical metallurgical defects associated with SLM such as balling effect is significantly affected by line energy density (LED). The optimal LED range is given by numerical and experimental results.

Similar content being viewed by others

References

B. Berman, 3-D printing: the new industrial revolution. Bus. Horizons. 55, 155–162 (2012)

J.P. Kruth, L. Froyen, J.V. Vaerenbergh et al., Selective laser melting of iron-based powder. J. Mater. Process. Technol. 149(1), 616–622 (2004)

D.D. Gu, W. Meiners, K. Wissenbach et al., Laser additive manufacturing of metallic components: materials, processes and mechanisms. Int. Mater. Rev. 57(3), 133–164 (2012)

F. Calignano, D. Manfredi, E.P. Ambrosio et al., Direct fabrication of joints based on direct metal laser sintering in aluminum and titanium alloys. Proc. CIRP. 21, 129–132 (2014)

S. Das, Physical aspects of process control in selective laser sintering of metals. Adv. Eng. Mater. 5(10), 701–711 (2003)

P. Yuan, D.D. Gu, D.H. Dai, Particulate migration behavior and its mechanism during selective laser melting of TiC reinforced Al matrix nanocomposites. Mater. Des. 82(5), 46–55 (2015)

A. Simchi, Direct laser sintering of metal powders: mechanism, kinetics and microstructural features. Mater. Sci. Eng. A. 428(1–2), 148–158 (2006)

A. Yadroitsev, I. Gusarov, Yadroitsava et al., Single track formation in selective laser melting of metal powders. J. Mater. Process. Technol. 210(12), 1624–1631 (2010)

Y.J. Shi, H. Shen, Z.Q. Yao et al., An analytical model based on the similarity in temperature distributions in laser forming. Opt. Lasers Eng. 45(1), 83–87 (2007)

Z. Chen, Y. Xiang, Z.Y. Wei et al., Thermal dynamic behavior during selective laser melting of K418 superalloy: numerical simulation and experimental verification. Appl. Phys. A. 124(4), 313 (2018)

K. Zeng, D. Pal, A review of thermal analysis methods in laser sintering and selective laser melting, in: Proceedings of Solid Freeform Fabrication Symposium. 23, 796–814 (2012)

P. Wei, Z.Y. Wei, Z. Chen et al., The AlSi10Mg samples produced by selective laser melting: single track, densification, microstructure and mechanical behavior. Appl. Surf. Sci. 408(30), 38–50 (2017)

C. Meier, R.W. Penny, Z. Yu et al., Thermophysical phenomena in metal additive manufacturing by selective laser melting: fundamentals, modeling. simulation and experimentation (2017). https://arxiv.org/abs/1709.09510

W.J. Sames, F.A. List, S. Pannala et al., The metallurgy and pro-cessing science of metal additive manufacturing. Int. Mater. Rev. 6608, 1–46 (2016)

W.E. King, A.T. Anderson, R.M. Ferencz et al., Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Appl. Phys. Rev. 2(4), 44–6210 (2015)

C. Körner, E. Attar, P. Heinl, Mesoscopic simulation of selective beam melting processes. J. Mater. Process. Technol. 211(6), 978–987 (2011)

G.B.M. Cervera, G. Lombera, Numerical prediction of temperature and density distributions in selective laser sintering processes. Rapid. Prototyping. J. 5(1), 12–26 (1999)

S. Kolossov, E. Boillat, R. Glardon et al., 3D FE simulation for temperature evolution in the selective laser sintering process. Int. J. Mach. Tools Manuf. 44(2), 117–123 (2004)

A. Hussein, L. Hao, C. Yan et al., Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Mater. Des. 52(24), 638–647 (2013)

A. Almangour, D. Grzesiak, J. Cheng et al., Thermal behavior of the molten pool, microstructural evolution, and tribological performance during selective laser melting of TiC/316L stainless steel nanocomposites: Experimental and simulation methods. J. Mater. Process. Technol. 257, 288–301 (2018)

Y. Li, D. Gu, Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder. Mater. Des. 63(2), 856–867 (2014)

Y. Li, D. Gu, Thermal behavior during selective laser melting of commercially pure titanium powder: Numerical simulation and experimental study. Addit. Manuf. 1(4), 99–109 (2014)

Q. Shi, D. Gu, M. Xia et al., Effects of laser processing parameters on thermal behavior and melting/solidification mechanism during selective laser melting of TiC/Inconel 718 composites. Opt. Laser Technol. 84, 9–22 (2016)

D. Dai, D. Gu, Thermal behavior and densification mechanism during selective laser melting of copper matrix composites: simulation and experiments. Mater. Des. 55(6), 482–491 (2014)

M.J. Xia, D.D. Gu, G.Q. Yu et al., Selective laser melting 3D printing of Ni-based superalloy: understanding thermodynamic mechanisms. Chin. Sci. Bull. 61(13), 1013–1022 (2016)

S.A. Khairallah, A.T. Anderson, A. Rubenchik et al., Laser powder-bed fusion additive manufacturing: physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 108, 36–45 (2016)

C. Chiumenti, E. Neiva, E. Salsi et al., Numerical modelling and experimental validation in selective laser melting. Addit Manuf. 18, 171–185 (2017)

B. Song, S. Dong, H. Liao et al., Process parameter selection for selective laser melting of Ti6Al4V based on temperature distribution simulation and experimental sintering. Int. J. Adv. Manuf. Technol. 61, 967–974 (2012)

J.N. Roux, Geometric origin of mechanical properties of granular materials. Phys. Rev. E 61(6), 6802 (2000)

G. Rong, G. Liu, D. Hou, C. Zhou, Effect of particle shape on mechanical behaviors of rocks: a numerical study using clumped particle model, Sci. World J. 2013(7), 289215–589215 (2013)

P. Wei, Z. Wei, Z. Chen et al., Thermal behavior in single track during selective laser melting of AlSi10Mg powder. Appl. Phys. A. 123(9), 604 (2017)

P. Wei, Z. Wei, Z. Chen et al., Numerical simulation and parametric analysis of selective laser melting process of AlSi10Mg powder. Appl. Phys. A. 123(8), 540 (2017)

Y. Lee, W. Zhang, Modeling of heat transfer, fluid flow and solidification microstructure of nickel-base superalloy fabricated by laser powder bed fusion. Addit. Manuf. 12, 178–188 (2016)

A. Masmoudi, C. Bolot, Coddet, Investigation of the laser–powder–atmosphere interaction zone during the selective laser melting process. J. Mater. Process. Technol. 225, 122–132 (2015)

C.W. Hirt, B.D. Nichols, Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 39(1), 201–225 (1981)

D. Dai, D. Gu, Influence of thermodynamics within molten pool on migration and distribution state of reinforcement during selective laser melting of AlN/AlSi10Mg composites. Int. J. Mach. Tools Manuf. 100, 14–24 (2016)

S. Rubenchik, S. Wu, I. Mitchell, M. Golosker, N. Leblanc, Peterson, Direct measurements of temperature-dependent laser absorptivity of metal powders. Appl. Opt. 54(24), 7230 (2015)

K.C. Mills, Recommended values of thermos physical properties for selected commercial alloys. Woodhead Publishing. 205–210 (2002)

K. Dai, L. Shaw, Finite element analysis of the effect of volume shrinkage during laser densification. Acta Mater. 53(18), 4743–4754 (2005)

V. Semak, A. Matsunawa, The role of recoil pressure in energy balance during laser materials processing. J. Phys. D: Appl. Phys. 30(18), 2541 (1999)

V.R. Voller, C. Prakash, A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. Int. J. Heat Mass Transf. 30(8), 1709–1719 (1987)

H.C. Min, C.L. Yong, D. Farson, Simulation of weld pool dynamics in the stationary pulsed gas metal arc welding process and inal weld shape. Weld. J. 85(12), 271–283 (2006)

B. Masmoudi, R. Bolot, C. Coddet, Investigation of the laser–powder–atmosphere interaction zone during the selective laser melting process. J. Mater. Process. Technol. 225, 122–132 (2015)

A.V. Gusarov, I. Smurov, Modeling the interaction of laser radiation with powder bed at selective laser melting. Physics Procedia. 5, 381–394 (2010)

E. Attar, C. Körner, Lattice Boltzmann model for thermal free surface lows with liquid–solid phase transition. Int. J. Heat Fluid Flow 32(1), 156–163 (2011)

Acknowledgements

The research is supported by Science Challenge Project TZ2018006-0301-01.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiang, Y., Zhang, S., Wei, Z. et al. Forming and defect analysis for single track scanning in selective laser melting of Ti6Al4V. Appl. Phys. A 124, 685 (2018). https://doi.org/10.1007/s00339-018-2056-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-2056-9