Abstract

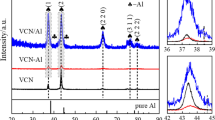

In present work, the microstructures, mechanical and tribological properties of VN and VN/Ag nanocomposite films deposited by pulsed laser deposition (PLD) technique were investigated and compared. The results indicate that both types of films display homogeneous and compact microstructures, and constitute stoichiometric polycrystals. Owing to the incorporation of Ag, the VN/Ag nanocomposite film exhibits a stronger texture along the [200] direction and a larger grain size of 16.5 nm as compared to that of the VN film (9.7 nm). Both types of films presented the same trend of decreasing friction coefficients with increasing temperature in wear tests. The oxidation of VN at elevated temperatures resulted in the formation of a series of vanadium oxides, such as V2O5, V3O7, V6O11, and V6O13, which significantly improved the tribological properties of the film. The VN/Ag nanocomposite films showed superior lubrication properties as compared to the VN films over the ertire range of the investigated temperatures. The metallic Ag provided lubrication to reduce friction at low temperatures. The lubricant vanadium oxides and silver vanadates (such as Ag3VO4, AgVO3) with a layered structure formed at higher temperatures were beneficial for enhancing the lubrication effect. The lowest friction coefficient of 0.08 at 900 °C is realized for VN/Ag nanocomposite films. The decrease in the friction coefficient with increasing temperature for VN films can be attributed to the formation of vanadium oxides on the worn surfaces at elevated temperatures. In case of VN/Ag nanocomposite films, apart from the vanadium oxides, silver vanadates with a layered structure played a critical role in improving the lubrication properties at higher temperatures.

Similar content being viewed by others

References

R. Franz, C. Mitterer, Vanadium containing self-adaptive low-friction hard coatings for high-temperature applications: a review. Surf. Coat. Technol. 228, 1–13 (2013)

O. Jantschner, C. Walter, C. Muratore, A.A. Voevodin, C. Mitterer, V-alloyed ZrO2 coatings with temperature homogenization function for high-temperature sliding contacts. Surf. Coat. Technol. 228, 76–83 (2013)

N. Fateh, G.A. Fontalvo, C. Mitterer, Tribological Properties of reactive magnetron sputtered V2O5 and VN–V2O5 coatings. Tribol. Lett. 30, 21–26 (2008)

F. Ge, P. Zhu, F. Meng, Q. Xue, F. Huang, Achieving very low wear rates in binary transition-metal nitrides: The case of magnetron sputtered dense and highly oriented VN coatings. Surf. Coat. Technol. 248, 81–90 (2014)

F. Huang, F. Ge, P. Zhu, H. Wang, F. Meng, S. Li, Superhard V-Si-N coatings (> 50GPa) with the cell-like nanostructure prepared by magnetron sputtering. Surf. Coat. Technol. 232, 600–605 (2013)

N. Fateh, G.A. Fontalvo, G. Gassner, C. Mitterer, Influence of high-temperature oxide formation on the tribological behaviour of TiN and VN coatings. Wear 262, 1152–1158 (2007)

K. Kutschej, P.H. Mayrhofer, M. Kathrein, P. Polcik, C. Mitterer, Influence of oxide phase formation on the tribological behaviour of Ti–Al–V–N coatings. Surf. Coat. Technol. 200, 1731–1737 (2005)

W. Tillmann, S. Momeni, F. Hoffmann, A study of mechanical and tribological properties of self-lubricating TiAlVN coatings at elevated temperatures. Tribol. Int. 66, 324–329 (2013)

J.H. Ouyang, T. Murakami, S. Sasaki, High-temperature tribological properties of a cathodic arc ion-plated (V,Ti)N coating. Wear 263, 1347–1353 (2007)

U. Wiklund, B. Casas, N. Stavlid, Evaporated vanadium nitride as a friction material in dry sliding against stainless steel. Wear 261, 2–8 (2006)

N. Fateh, G.A. Fontalvo, G. Gassner, C. Mitterer, The beneficial effect of high-temperature oxidation on the tribological behaviour of V and VN coatings. Tribol. Lett. 28, 1–7 (2007)

S.M. Aouadi, D.P. Singh, D.S. Stone, K. Polychronopoulou, F. Nahif, C. Rebholz et al., Adaptive VN/Ag nanocomposite coatings with lubricious behavior from 25 to 1000 °C. Acta Mater. 58, 5326–5331 (2010)

C. Muratore, A.A. Voevodin, J.J. Hu, J.S. Zabinski, Tribology of adaptive nanocomposite yttria-stabilized zirconia coatings containing silver and molybdenum from 25 to 700 °C. Wear 261, 797–805 (2006)

A. C.Muratore, A. Voevodin, J.J. Hu, J.G. Jones, J.S. Zabinski. Growth and characterization of nanocomposite yttria-stabilized zirconia with Ag and Mo. Surf. Coat. Technol. 200, 1549–1554 (2005)

J. Chen, Y. An, J. Yang, X. Zhao, F. Yan, H. Zhou et al., Tribological properties of adaptive NiCrAlY–Ag–Mo coatings prepared by atmospheric plasma spraying. Surf. Coat. Technol. 235, 521–528 (2013)

E. Sadri, F. Ashrafizadeh, Structural characterization and mechanical properties of plasma sprayed nanostructured Cr2O3-Ag composite coatings. Surf. Coat. Technol. 236, 91–101 (2013)

X. Shi, Z. Xu, M. Wang, W. Zhai, J. Yao, S. Song et al., Tribological behavior of TiAl matrix self-lubricating composites containing silver from 25 to 800 °C. Wear 303, 486–494 (2013)

X. Shi, J. Yao, Z. Xu, W. Zhai, S. Song, M. Wang et al., Tribological performance of TiAl matrix self-lubricating composites containing Ag, Ti3SiC2 and BaF2/CaF2 tested from room temperature to 600 °C. Mater. Design 53, 620–633 (2014)

X. Shi, S. Song, W. Zhai, M. Wang, Z. Xu, J. Yao et al., Tribological behavior of Ni3Al matrix self-lubricating composites containing WS2, Ag and hBN tested from room temperature to 800 °C. Mater. Design 55, 75–84 (2014)

J. Chen, X. Zhao, H. Zhou, J. Chen, Y. An, F. Yan, Microstructure and tribological property of HVOF-sprayed adaptive NiMoAl–Cr3C2–Ag composite coating from 20 °C to 800 °C. Surf. Coat. Technol. 258, 1183–1190 (2014)

S. Zhu, F. Li, J. Ma, J. Cheng, B. Yin, J. Yang et al., Tribological properties of Ni3Al matrix composites with addition of silver and barium salt. Tribol. Int. 84, 118–123 (2015)

D.V. Shtansky, A.V. Bondarev, P.V. Kiryukhantsev-Korneev, T.C. Rojas, V. Godinho, A. Fernández, Structure and tribological properties of MoCN-Ag coatings in the temperature range of 25–700 °C. Appl. Surf. Sci. 273, 408–414 (2013)

J.H. Hsieh, C.H. Chiu, C. Li, W. Wu, S.Y. Chang, Development of anti-wear and anti-bacteria TaN-(Ag,Cu) thin films—a review. Surf. Coat. Technol. 233, 159–168 (2013)

D.S. Stone, S. Harbin, H. Mohseni, J.E. Mogonye, T.W. Scharf, C. Muratore et al., Lubricious silver tantalate films for extreme temperature applications. Surf. Coat. Technol. 217, 140–146 (2013)

D.S. Stone, J. Migas, A. Martini, T. Smith, C. Muratore, A.A. Voevodin et al., Adaptive NbN/Ag coatings for high temperature tribological applications. Surf. Coat. Technol. 206, 4316–4321 (2012)

H. Guo, W. Chen, Y. Shan, W. Wang, Z. Zhang, J. Jia, Microstructures and properties of titanium nitride films prepared by pulsed laser deposition at different substrate temperatures. Appl. Surf. Sci. 357, 473–478 (2015)

D. Craciun, G. Socol, N. Stefan, G. Dorcioman, M. Hanna, C.R. Taylor et al., The effect of deposition atmosphere on the chemical composition of TiN and ZrN thin films grown by pulsed laser deposition. Appl. Surf. Sci. 302, 124–128 (2014)

W.C. Oliver, An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992)

J.C. Caicedo, G. Zambrano, W. Aperador, L. Escobar-Alarcon, E. Camps, Mechanical and electrochemical characterization of vanadium nitride (VN) thin films. Appl. Surf. Sci. 258, 312–320 (2011)

M. Pfeiler-Deutschmann, P.H. Mayrhofer, K. Chladil, M. Penoy, C. Michotte, M. Kathrein et al., Effect of wavelength modulation of arc evaporated Ti–Al–N/Ti–Al–V–N multilayer coatings on microstructure and mechanical/tribological properties. Thin Solid Films 581, 20–24 (2015)

M. Pfeiler, K. Kutschej, M. Penoy, C. Michotte, C. Mitterer, M. Kathrein, The effect of increasing V content on structure, mechanical and tribological properties of arc evaporated Ti–Al–V–N coatings. Int. J. Refract. Metals Hard Mater. 27, 502–506 (2009)

A.A. Voevodin, J.J. Hu, J.G. Jones, T.A. Fitz, J.S. Zabinski, Growth and structural characterization of yttria-stabilized zirconia–gold nanocomposite films with improved toughness. Thin Solid Films 401, 187–195 (2001)

D. Stone, J. Liu, D.P. Singh, C. Muratore, A.A. Voevodin, S. Mishra et al., Layered atomic structures of double oxides for low shear strength at high temperatures. Scripta Mater. 62, 735–738 (2010)

C. Muratore, J.E. Bultman, S.M. Aouadi, A.A. Voevodin, In situ Raman spectroscopy for examination of high temperature tribological processes. Wear 270, 140–145 (2011)

Acknowledgements

The authors gratefully acknowledge the National Natural Science Foundation of China (Grant no. 51665026), the Young Science and Technology Foundation of Gansu Province (Grant no. 1506RJYA058), and the Research Foundation of Education Bureau of Gansu Province (Grant no. 2014A-119) in China for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, H., Lu, C., Zhang, Z. et al. Comparison of microstructures and properties of VN and VN/Ag nanocomposite films fabricated by pulsed laser deposition. Appl. Phys. A 124, 694 (2018). https://doi.org/10.1007/s00339-018-2055-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-2055-x