Abstract

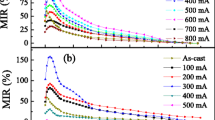

We produced NiFeMo ribbons by electrodeposition technique under applied currents ranging from 40 to 240 mA. The SEM analysis showed a uniform and crack-free coating. Then, we measured the transverse and longitudinal magnetoimpedance of ribbons. We also obtained the hysteresis loops of the ribbons by means of magnetooptical Kerr effect to investigate their magnetic properties. The result showed that the increase in deposition current density caused a decline in the magnetic softness of the ribbons so that some of the ribbons exhibited an exchange spring effect. The magnetic hardening also caused a reduction in the magnetoimpedance response. We also theoretically calculated the susceptibility of a ribbon by considering the random magnetic anisotropy. The multi-peak behavior of susceptibility is in agreement with the multi-peak behavior of magnetoimpedance.

Similar content being viewed by others

References

T.K. Das, P. Banerji, S.K. Mandal, Giant magnetoimpedance intrinsic impedance and voltage sensitivity of rapidly solidified Co\(_{66}\)Fe\(_2\)Cr\(_4\)Si\(_{13}\)B\(_{15}\) amorphous wire for highly sensitive sensors applications. Appl. Phys. A 122, 939 (2016)

G.L.S. Vilela, J.G. Monsalve, A.R. Rodrigues, A. Azevedo, F.L.A. Machado, Giant magnetoimpedance effect in a thin-film multilayer meander-like sensor. J. Appl. Phys. 121, 124501 (2017)

X. Sun, J. Du, Z. Zhu, J. Wang, Q. Liu, Enhanced GMI effect in NiZn-ferrite-modified Fe-based amorphous ribbons. Appl. Phys. A 119, 1277–1281 (2015)

E.F. Silva, R.B. da Silva, M. Gamino, A.M.H. de Andrade, M. Vazquez, M.A. Correa, F. Bohn, Asymmetric magnetoimpedance effect in ferromagnetic multilayered biphase films. J. Magn. Magn. Mater. 393, 260–264 (2015)

Y. Honkura, Development of amorphous wire type MI sensors for automobile use. J. Magn. Magn. Mater. 249, 375–381 (2002)

G.V. Kurlyandskaya, M.L. Sanchez, B. Hernando, V.M. Prida, P. Gorria, M. Tejedor, Giant-magnetoimpedance-based sensitive element as a model for biosensors. Appl. Phys. Lett. 82, 3053–3055 (2003)

T. Wang, Y. Zhou, C. Lei, J. Lei, Z. Yang, Development of an ingenious method for determination of dynabeads protein A based on a giant magnetoimpedance sensor. Sens. Actuat B Chem. 186, 727–733 (2013)

M. Vazquez, Soft magnetic wires. Phys. B 299, 302–313 (2001)

C. Tannous, J. Gieraltowski, Giant magneto impedance and its applications. J. Mater. Sci. Mater. Electron. 15, 125–133 (2004)

A. Zhukov, A. Chizhik, M. Ipatov, A. Talaat, J.M. Blanco, A. Stupakiewicz, V. Zhukova, Giant magnetoimpedance effect and domain wall dynamics in Co-rich amorphous microwires. J. Appl. Phys. 117, 043904 (2015)

V. Zhukova, A. Talaat, M. Ipatov, J.J. Del Val, L. Gonzalez-Legarreta, B. Hernando, A. Zhukov, Effect of nanocrystallization on magnetic properties and GMI effect of Fe-rich microwires. J. Electron. Mater. 43, 4540–4547 (2014)

R. Mardani, A. Amirabadizadeh, M. Ghanaatshoar, Angular dependence of giant magneto impedance and magnetic characteristic of Co-based wire in different magnetic field ranges. Mod. Phys. Lett. B 28, 1450197 (2014)

A. Zhukov, M. Ipatov, M. Churyukanova, A. Talaat, J.M. Blanco, V. Zhukova, Trends in optimization of giant magnetoimpedance effect in amorphous and nanocrystalline materials. J. Alloys. Compd. (2017)

L. Xie, X. Li, J.T. Zou, H.L. Pan, W.H. Xie, Z.J. Zhao, Optimized giant magneto-impedance effect in electroless-deposited NiFeP/Cu composite wires. Surf. Coat. Technol (2017)

R. Kammouni, G.V. Kurlyandskaya, M. Vázquez, S.O. Volchkov, Magnetic properties and magnetoimpedance of short CuBe/CoFeNi electroplated microtubes. Sens. Actuat. A 248, 155–161 (2016)

T. Eggers, A. Leary, M. McHenry, J. Marcin, I. Škorvánek, H. Srikanth, M.H. Phan, Correlation between domain structure, surface anisotropy and high frequency magneto-impedance in Joule annealed CoFe-based melt-spun ribbons. J. Alloys. Compd. 682, 799–804 (2016)

M. Banerjee, R. Banerjee, A.K. Majumdar, A. Mookerjee, B. Sanyal, A.K. Nigam, Magnetism in NiFeMo disordered alloys: experiment and theory. Phys. B 405, 4287–4293 (2010)

D. Oleksakova, P. Kollar, J. Fuzer, M. Kusy, S. Roth, K. Polanski, The influence of mechanical milling on structure and soft magnetic properties of NiFe and NiFeMo alloys. J. Magn. Magn. Mater. 316, 838–841 (2007)

G. Nabiyouni, S. Saeidi, I. Kazeminezhad, Magnetic and nanostructural characteristics of electrodeposited supermalloy (Ni–Fe–Mo) thin films. Res. Rev. Mater. Sci. Chem. 1, 1–14 (2012)

J. Velleuer, A. Mun, H. Yakabchuka, C. Schiefer, A. Hackl, E. Kisker, Giant magneto impedance in electroplated NiFeMo/Cu microwires. J. Magn. Magn. Mater. 311, 651–657 (2007)

A. Munoz, C. Schiefer, T. Nentwig, W. Man, E. Kiske, Magneto impedance of electroplated NiFeMo/Cu microwires for magnetic sensors. J. Appl. Phys. 40, 5013–5020 (2007)

Z.Q. Qiu, S.D. Bader, Surface magneto-optic Kerr effect. Rev. Sci. Instrum. 71, 1243–1255 (2000)

M. Ghanaatshoar, N. Azad, M.H. Banitaba, B. Shokri, Giant magnetoimpedance effect of ac–dc Joule annealed electroplated NiFe/Cu composite wires. Phys. Status Solid C 8, 3055–3058 (2011)

W.P. Taylor, M. Schneider, H. Baltes, M.G. Allen, A NiFeMo electroplating bath for micromachined structures. Electrochem. Solid State Lett. 2, 624–626 (1999)

M. Banerjee, A.K. Majumdar, S. Rai, P. Tiwari, G.S. Lodha, A. Banerjee, K.G.M. Nair, J. Sarkar, R.J. Choudhary, D.M. Phase, Room temperature ferromagnetism down to 10 nanometer Ni–Fe–Mo alloy films. Thin Solid Films 545, 358–390 (2013)

H. Wang, J. Yan, S. Li, X. Zhang, Q. Jiang, Noble-metal-free NiFeMo nanocatalyst for hydrogen generation from the decomposition of hydrous hydrazine. J. Mater. Chem. A 3, 121–124 (2014)

H. Seet, X. Li, Z. Zhao, L. Wong, H. Zheng, K. Lee, Current density effect on magnetic properties of nanocrystalline electroplate Ni\(_{80}\)Fe\(_{20}\)/Cu composite wires. J. Magn. Magn. Mater. 302, 113–117 (2006)

M.A. Islam, M. Moniruzzaman, Anomalous electrodeposition of Fe–Ni alloy coating from simple and complex baths and its magnetic property. Iium Eng. J. 10, 108–122 (2009)

A. Chizhik, C. Garcia, A. Zhukov, J. Gonzalez, L. Dominguez, J.M. Blancob, Investigation of surface magnetization reversal in Co-rich amorphous microwires with magneto-impedance effect. Phys. B 384, 5–8 (2006)

V. Setoodeh, S.I. Hosseini, M. Ghanaatshoar, B. Shokri, Optical exchange spring effect in RF-annealed Fe-based amorphous ribbons. Phys. B 408, 39–42 (2013)

E. Goto, N. Yahashi, T. Miyashita, K. Nakagawa, Magnetization and switching characteristics of composite thin films. J. Appl. Phys. 36, 2951–2958 (1965)

G. Kotagiri, S.D. Ramarao, G. Markandeyulu, Magnetoimpedance studies on laser and microwave annealed Fe\(_{66}\)Ni\(_7\)si\(_7\)B\(_{20}\) ribbons. J. Magn. Magn. Mater. 382, 43–48 (2015)

Z. Zhou, Y. Zhou, Y. Cao, The investigation of giant magnetoimpedance effect in meander NiFe/Cu/NiFe film. J. Magn. Magn. Mater. 320, 967–970 (2008)

V. Zhukova, A. Zhukov, K.L. Garcia, V. Kraposhin, A. Prokoshin, J. Gonzalez, M. Vazquez, Magnetic properties and GMI of soft melt-extracted magnetic amorphous fibers. Sens. Actuat. A 106, 225–229 (2003)

D. Atkinson, P.T. Squire, Phenonemological model for magnetoimpedance in soft ferromagnets. J. Appl. Phys. 83, 6569–6571 (1998)

V. Panina, K. Mohri, T. Uchiyama, M. Noda, K. Bushida, Giant magneto-impedance in Co-rich amorphous wires and films. IEEE Trans. Magn. 31, 1249–1260 (1995)

F.L.A. Machado, M. Rezende, A theoretical model for the giant magnetoimpedance in ribbons of amorphous soft-ferromagnetic alloys. J. Appl. Phys. 79, 6558–6560 (1996)

R.L. Sommer, C.L. Chien, Giant magnetoimpedance effects in Metglas 2705M. J. Appl. Phys. 79, 5139–5141 (1996)

S.Q. Xiao, Y.H. Liu, Y.Y. Dai, L. Zhang, S.X. Zhou, G.D. Liu, Giant magnetoimpedance effect in sandwiched films. J. Appl. Phys. 35, 4127–4130 (1999)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kalhor, S., Ghanaatshoar, M. & Aliaskarisohi, S. Magnetoimpedance and magnetooptical properties of electrodeposited NiFeMo ribbons. Appl. Phys. A 124, 229 (2018). https://doi.org/10.1007/s00339-018-1636-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-1636-z