Abstract

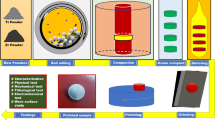

Studies on the corrosion resistance of magnesium alloys, which are widely applied as biomaterials, have increased in recent years. In this work, zirconium nitride (ZrN) coatings were deposited on AZ91 magnesium alloy through ion-beam sputtering at 473 K with 0.3, 0.4, 0.5, and 0.6 nitrogen proportions [F(N2)] in ionized gas. X-ray diffraction, profilometry, hardness tests, scanning electron microscopy, and potentiodynamic polarization techniques were used to analyze the structure, thickness, adhesion, microstructure, and corrosion resistance of coated samples, respectively. Results showed that the (111) crystalline orientation dominated in all coatings. Williamson–Hall technique revealed that the crystallite size of ZrN films decreased from 73 to 20 nm with increasing F(N2), and compressive microstrain increased from 0.004 to 0.030. Film thicknesses were inversely correlated with N2 amount and significantly decreased from 1.7 to 0.8 µm. The maximum dP/dr ratio, a dependent factor of adhesion, was 0.04 kg/cm for the film deposited under the F(N2) value of 0.5. The corrosion potential of coated samples was not significantly different from that of uncoated AZ91. Under the F(N2) value of 0.6, corrosion current density slightly decreased from 14 to 9.7 µA/cm2 and significantly increased to 13.5 µA/cm2. Results indicated that ZrN film deposited under the F(N2) value of 0.5 showed high adhesion and corrosion resistance.

Similar content being viewed by others

References

R.-C. Zeng et al., Corrosion resistance of cerium-doped zinc calcium phosphate chemical conversion coatings on AZ31 magnesium alloy. Trans Nonfe. Met Soc China 26, 472–483 (2016)

D. Shen et al., Effect of cerium and lanthanum additives on plasma electrolytic oxidation of AZ31 magnesium alloy. J. Rare Earths 31(12) 1208–1213 (2013)

C.H. Chang et al., Fatigue property improvements of ZK60 magnesium alloy: effects of thin film metallic glass. Thin Solid Films 616, 431–436 (2016)

W. Jin et al., Improved corrosion resistance of Mg-Y-RE alloy coated with niobium nitride. Thin Solid Films 572, 85–90 (2014)

S.R. Kiahosseini et al., Electrochemical evaluation of hydroxyapatite/ZrN coated magnesium biodegradable alloy in Ringer solution as a simulated body fluid. J Chem Health Risks 5(1), 45–53 (2015)

X. Cui et al., Corrosion behaviors in physiological solution of cerium conversion on AZ31 magnesium alloy coatings. Appl. Surf. Sci. 257, 9703–9709 (2011)

C. Liu et al., Corrosion behavior of AZ91 magnesium alloy treated by plasma immersion ion implantation and deposition in artificial physiological fluids. Thin Solid Films 516, 422–427 (2007)

R.-C. Zeng et al., Corrosion resistance of silane-modified hydroxide zinc carbonate film on AZ31 magnesium alloy. Acta Metall. Sin (English letters) 28(3) 373–380 (2015)

I.N.Q. Arruda et al., Application of chitosan matrix for delivery of rutin. J. Iran. Chem. Soc. 14(3), 561–566 (2017)

H. Yu et al., Structure and in vitro bioactivity of ceramic coatings on magnesium alloys by microarc oxidation. Appl. Surf. Sci. 388(A) 114–119 (2016)

D.-C. Li et al., Ranking the significance of fermentation conditions on the volatile organic compounds of Tuber melanosporum fermentation system by combination of head-space solid phase microextraction and chromatographic fingerprint similarity analysis. Bioprocess Biosyst 37(3) 543–552 (2014)

S. Fooladi, S.R. Kiahosseini, Creation and investigation of chitin/HA double-layer coatings on AZ91 magnesium alloy by dipping method. J. Mater. Res. 32(13), 1–10 (2017)

K.A. Gruss, R.F. Davis, Adhesion measurement of zirconium nitride and amorphous silicon carbide coatings to nickel and titanium alloys. Surf. Coat. Technol. 114, 156–168 (1999)

E. Kelesoglu, C. Mitterer, M. Urgen, Corrosion characteristics of plain carbon steel coated with TiN and ZrN under high-flux ion bombardment. Surf. Coat. Technol. 160, 82–86 (2002)

A. Rizzo et al., Sputtering deposition and characterization of zirconium nitride and oxynitride films. Thin Solid Films 520, 3532–3538 (2012)

K. Kukli et al., Atomic layer deposition of zirconium dioxide from zirconium tetrachloride and ozone. Thin Solid Films 589, 597–604 (2015)

M.M. Larijani et al., Nitrogen effect on corrosion resistance of ion beam sputtered nanocrystalline zirconium nitride films. Surf Coat Technol 203, 2591–2594 (2009)

E. Kusano et al., Adhesion and hardness of compositionally gradient TiO rTirTiN, ZrO rZrrZrN, and TiO rTirZrrZrN coatings. Thin Solid Films 334, 151–155 (1998)

J.-W. Lee et al., Effects of substrate bias frequencies on the characteristics of chromium nitride coatings deposited by pulsed DC reactive magnetron sputtering. Surf Coat Technol 203, 721–725 (2008)

H.-D. Kim et al., Oxygen-doped zirconium nitride based transparent resistive random access memory devices fabricated by radio frequency sputtering method. J. Alloys Compd. 675, 183–186 (2016)

E. Kaminska et al., Transparent p-type ZnO films obtained by oxidation of sputter-deposited Zn3N2. Solid State Commun. 135(1–2) 11–15 (2005)

W.-J. Chou, G.-P. Yu, J.-H. Huang, Corrosion resistance of ZrN films on AISI 304 stainless steel substrate. Surf. Coat. Technol. 167, 59–67 (2003)

D.M. Devia et al., TiAlN coatings deposited by triode magnetron sputtering varying the bias voltage. Appl. Surf. Sci. 257(14) 6181–6185 (2011)

E.K. Tentardini, E. Blando, R. Hübler, TiN structural modifications induced by bias voltage in a new dynamic controlled magnetron sputtering apparatus. Nucl. Instrum. Methods Phys. Res. Sect. B 175–177, 626–629 (2001)

L. Gao, S. Jiang, R. Li, Effect of sputtering pressure on structure and dielectric properties of bismuth magnesium niobate thin films prepared by RF magnetron sputtering. Thin Solid Films 603, 391–394 (2016)

J. Kim et al., A new indentation cracking method for evaluating interfacial adhesion energy of hard films. Thin Solid Films 441, 172–179 (2003)

M. Nesladek et al., Adhesion of diamond coatings on cemented carbides. Thin Solid Films 270, 184–188 (1995)

L. Chang-Hao, M. Zhan-Qi, Effects of different simulated fluids on anticorrosion biometallic materials. Trans. Nonfe. Met. Soc. China 11(4), 579–582 (2001)

J. Sakaliuniene et al., Investigation of structural and optical properties of GDC thin films deposited by reactive magnetron sputtering. Acta Phys Pol. A. 120(1), 63–65 (2011)

J.H. Huang, C.H. Ho, G.P. Yu, Effect of nitrogen flow rate on the structure and mechanical properties. Mater. Chem. Phys. 102, 31–38 (2007)

V. Chawla, R. Jayaganthan, R. Chandra, Structural characterizations of magnetron sputtered. Mater. Charact. 59, 1015–1020 (2008)

B. Subramanian, K. Prabakaran, M. Jayachandran, Influence of nitrogen flow rates on materials properties of CrNx films. Bull. Mater. Sci 35(4), 505–511 (2012)

M. Chahkandi, M. Mirzaei, Structural and particle size evolution of sol–gel-derived nanocrystalline hydroxyapatite. J. Iran. Chem. Soc. 14(3), 567–575 (2016)

M.P.C. Kalita et al., X-ray diffraction line profile analysis of chemically synthesized lead sulphide nanocrystals. Mater. Lett. 87, 84–86 (2012)

K.A. Aly et al., Lattice strain estimation for CoAl2O4 nano particles using Williamson-Hall analysis. J. Alloys Compd. 676, 606–612 (2016)

S.R. Kiahosseini et al., Structural and corrosion characterization of hydroxyapatite/zirconium nitride-coated AZ91 magnesium alloy by ion beam sputtering. Appl. Surf. Sci. 401, 172–180 (2017)

A.K. Shirazi, S.R. Kiahosseini, Hot corrosion of the ceramic composite coating Ni3Al–Al2O3–Al2O3/MgO plasma sprayed on 316L stainless steel. Int. J. Mater. Res. 108(8), 675–680 (2017)

H. Jiménez, E. Restrepo, A. Devia, Effect of the substrate temperature in ZrN coatings grown by the pulsed arc technique studied by XRD. Surf. Coat. Technol. 201(3–4), 1594–1601 (2006)

S. Zhang et al., Residual stress characterization of diamond-like carbon coatings by an X-ray diffraction method. Surf. Coat. Technol. 122, 219–224 (1999)

S.R. Kiahosseini et al., Adhesion, microstrain, and corrosion behavior of ZrN-coated AZ91 alloy as a function of temperature. J Mater Res 28(19), 2709–2714 (2013)

Y. Zhang, Y.-P. Zhao, Applicability range of Stoney’s formula and modified formulas for a film/substrate bilayer. J Appl Phys. 99, 13/1–13/7 (2006)

Y.P. Zhao, L.S. Wang, T.X. Yu, Mechanics of adhesion in MEMS—a review. J. Adhes. Sci. Technol. 17(4), 519–546 (2003)

K.A. Habib et al., Breakdown and evolution of the protective oxide scales of AISI 304 and AISI 316 stainless steels under high-temperature oxidation. Int J Corros. 2011, 1–10 (2011)

S. Choi et al., Tin nitride thin films fabricated by reactive radio frequency magnetron sputtering at various nitrogen gas ratios. Thin Solid Films 571, 84–89 (2014)

F.C.M. van de Pol et al., R.f. planar magnetron sputtered ZnO films I: Structural properties. Thin Solid Films 204(2), 349–364 (1991)

Z. Xin, S. Xiao-Hui, Z. Dian-Lin, Thickness dependence of grain size and surface roughness for dc magnetron sputtered Au films. Chin. Phys. B 19(8), 0868021–0868024 (2010)

H. Altun, H. Sinici, Corrosion behaviour of magnesium alloys coated with TiN by cathodic arc deposition in NaCl and Na2SO4 solutions. Mater Charact. 59, 266–270 (2008)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kiahosseini, S.R., Mojtahedzadeh Larijani, M. Effects of nitrogen gas ratio on the structural and corrosion properties of ZrN thin films grown on biodegradable magnesium alloy by ion-beam sputtering. Appl. Phys. A 123, 759 (2017). https://doi.org/10.1007/s00339-017-1389-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-017-1389-0