Abstract

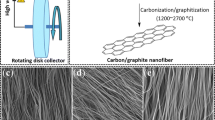

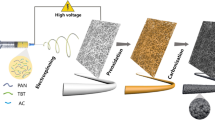

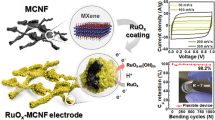

The titanium oxide (TiO x (x = 1 ~ 2))/carbon (C) nanofibers (NFs) films were prepared by electrospinning, followed by pre-oxidation and carbonization, and the effects of pre-oxidation temperature on the TiO x /C NFs films were investigated. The results showed that pre-oxidation temperature not only affected the composition of TiO x (TiO2 or TiO2/TiO mixture) in CNFs, but also had great influence on forming aromatic ring structure of graphite layer. As a result, the mechanical properties and conductivity of the TiO x /C NFs film were deeply influenced by pre-oxidation temperature. With the pre-oxidation temperature increasing, the tensile strength, elongation at break, and bending elastic modulus of TiO x /C NFs films improved, reached the largest values, and then decreased. When pre-oxidation temperature was 240 °C, the tensile strength, elongation at break and bending elastic modulus had the largest values of 7.10 MPa, 3.56%, and 9.0 cN/cm2, respectively. All the TiO x /C NFs films exhibited well flexibility. Moreover, with the pre-oxidation temperature no more than 260 °C, the average square resistances of TiO x /C NFs films were about 10 Ω/sq. With the temperature being over 280 °C, the average square resistances of TiO x /C NFs films greatly increased and reached about 22 Ω/sq. These flexible films can be applied in efficient catalyst flexible scaffolds and flexible electronic devices.

Similar content being viewed by others

References

S. Bal, Experimental study of mechanical and electrical properties of carbon nanofiber/epoxy composites. Mater. Des. 31, 2406–2413 (2010)

S.K. Nataraj, B.H. Kim, J.H. Yun, D.H. Lee, T.M. Aminabhavi, K.S. Yang, Effect of added nickel nitrate on the physical, thermal and morphological characteristics of polyacrylonitrile-based carbon nano fibers. Mat. Sci. Eng. B 162, 75–81 (2009)

J.E. Yang, I. Jang, M. Kim, S.H. Baeck, S. Hwang, S.E. Shim, Electrochemically polymerized vine-like nanostructured polyaniline on activated carbon nanofibers for supercapacitor. Electrochim. Acta 111, 136–143 (2013)

N.A. Garcia-Gomez, H.A. Mosqueda, D.I. Garcia-Gutierrez, E.M. Sanchez, Electrochemical behavior of TiO2/carbon dual nanofibers. Electrochim. Acta 116, 19–25 (2014)

J.S. Bonso, G.D. Kalaw, J.P. Ferraris, High surface area carbon nanofibers derived from electrospun PIM-1 for energy storage applications. J. Mater. Chem. A 2, 418–424 (2014)

D. Gao, L. Wang, C. Wang, Q. Wei, Electrospinning of porous carbon nanocomposites for supercapacitor. Fibers Polym. 16, 421–425 (2015)

Manoharan MP, Sharma A, Desai AV, Haque MA, Bakis CE, Wang KW. The interfacial strength of carbon nanofiber epoxy composite using single fiber pullout experiments. Nanotechnology 20(29), 5 (2009)

C. Kang, R. Baskaran, J. Hwang, B.C. Ku, W. Choi, Large scale patternable 3-dimensional carbon nanotube–graphene structure for flexible Li-ion battery. Carbon 68, 493–500 (2014)

O. Monereo, S. Claramunt, M.M. Marigorta, M. Boix, R. Leghrib, J.D. Prades, A. Cornet, P. Merino, C. Merino, A. Cirera, Flexible sensor based on carbon nanofibers with multifunctional sensing features. Talanta 107, 239–247 (2013)

K.J. Green, D.R. Dean, U.K. Vaidya, E. Nyairo, Multiscale fiber reinforced composites based on a carbon nanofiber/epoxy nanophased polymer matrix: synthesis, mechanical, and thermomechanical behavior. Compos. Part A: Appl. Sci. Manuf. 40, 1470–1475 (2009)

C.K. Liu, K. Lai, W. Liu, M. Yao, R.J. Sun, Preparation of carbon nanofibres through electrospinning and thermal treatment. Polym. Int. 58, 1341–1349 (2009)

J. Li, E.H. Liu, W. Li, X.Y. Meng, S.T. Tan, Nickel/carbon nanofibers composite electrodes as supercapacitors prepared by electrospinning. J. Alloys Compd. 478, 371–374 (2009)

Zhou Z, Lai C, Zhang L, Qian Y, Hou H, Reneker DH, et al. Development of carbon nanofibers from aligned electrospun polyacrylonitrile nanofiber bundles and characterization of their microstructural, electrical, and mechanicalproperties. Polymer 50(13):2999–3006 (2009)

Zhou Z, Liu K, Lai C, Zhang L, Li J, Hou H, et al. Graphitic carbon nanofibers developed from bundles of aligned electrospun polyacrylonitrile nanofibers containing phosphoric acid. Polymer 51(11):2360–2367 (2010)

L. Huang, N.N. Bui, S.S. Manickam, J.R. McCutcheon, Controlling electrospun nanofiber morphology and mechanical properties using humidity. J. Polym. Sci. Part B: Polym. Phys. 49, 1734–1744 (2011)

M. Inagaki, Y. Yang, F. Kang, Carbon nanofibers prepared via electrospinning. Adv. Mater. 24, 2547–2566 (2012)

S.K. Nataraj, K.S. Yang, T.M. Aminabhavi, Polyacrylonitrile-based nanofibers—a state-of-the-art review. Prog. Polym. Sci. 37, 487 (2012)

Zhou Z, Liu K, Lai C, Zhang L, Li J, Hou H, et al. Graphitic CNFs developed from bundles of aligned electrospun polyacrylonitrile nanofibers containing phosphoric acid. Polymer 51(11), 2360–2367 (2010,)

Y. Gao, V. Presser, L. Zhang, J.J. Niu, J.K. McDonough, C.R. Pérez, H. Lin, H. Fong, Y. Gogotsi, High power supercapacitor electrodes based on flexible TiC-CDC nano-felts. J. Power Sources 201, 368–375 (2012)

C. Lai, Z. Zhou, L. Zhang, X. Wang, Q. Zhou, Y. Zhao, Y. Wang, X.-F. Wu, Z. Zhu, H. Fong, Free-standing and mechanically flexible mats consisting of electrospun carbon nanofibers made from a natural product of alkali lignin as binder-free electrodes for high-performance supercapacitors. J. Power Sources 247, 134–141 (2014)

Rahaman M, Ismail AF, Mustafa A. A review of heat treatment on polyacrylonitrile fiber. Polym. Degrad. Stab. 92(8), 1421–1432 (2007)

R.H. wang, Z.R. Yue, R.Y. Li, J. Liu. AsPects on interaetion between multistage stabilization of Polyaerylonitrile Precursor and meehanieal ProPerties of carbon fibers. J Appl. Polym. Sci. 56(2):289–300 (1995)

Fitzer E, Frohs W, Heine M. Optimization of stabilization and carbonization treatment of PAN fibres and structural characterization of the resulting carbon fibres. Carbon 24(4), 387–395 (1986)

Mathur R, Bahl O, Mittal J. A new approach to thermal stabilisation of PAN fibres. Carbon 30(4):657–663 (1992).

Gupta A, Harrison IR. New aspects in the oxidative stabilization of PAN-based carbon fibers. Carbon 34(11), 1427–1445 (1996)

Gupta A, Harrison IR. New aspects in the oxidative stabilization of PAN-based carbon fibers: II. Carbon 35(6):809–818 (1997)

Mittal J, Bahl OP, Mathur RB. Single step carbonization and graphitization of highly stabilized PAN fibers. Carbon 35(8), 1196–1197 (1997)

W. Watt, W. Johnson, Mechanism of oxidation of Polyacrylonitrile fibers. Nature 257, 210–212 (1975)

E. Fitzer, D.J. Muller, The influence of oxygen on the chemical reactions during Stabilization of Pan as carbon fiber Preeursor. Carbon 13(1), 63–69 (1975)

A.E. Standage, R.D. Matkowsky, Thermal oxidation of polyacrylonitrile. Eur. Polym. J. 7(7), 775–783 (1971)

J. Liu, W. Zhang, Comparative study on structural changes during thermal PAN precursors. J. Appl. Polym. Sci. 97, 2047 (2005)

S.B. Warner, H.P. Jr L, D.R. Uhlmann, Oxidative stabilization of acrylic fibres. J. Mater. Sci. 14(3), 1893–1900 (1979)

A. GuPta, New aspects in the oxidative stabilization of Polyacrylonitrile-based carbon fibers. PhD. thesis, The Pennsylvania State University (1996)

O.P. Bahl, L.M. Manoeha, Charaeterization of oxidized PAN fibers. Carbon 12(4), 417–423 (1974)

A.K. GuPta, D.K. Paliwal, P. Bajaj, Effect of an acidic comonomer on thermooxidative stabilization of Polyacrylonitrile. J. Appl. Polym. Sci. 58, 1161–1174 (1995)

Acknowledgements

The financial support of this work was provided by the Program for Zhejiang Provincial Natural Science Foundation of China (LZ16E020002), Innovative Research Team of Zhejiang Sci-Tech University (15010039-Y), and National Natural Science Foundation of China (51402260).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, Y., Xie, X., Song, L. et al. The preparation and properties of the flexible titanium oxide/carbon nanofibers film. Appl. Phys. A 123, 267 (2017). https://doi.org/10.1007/s00339-017-0901-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-017-0901-x