Abstract

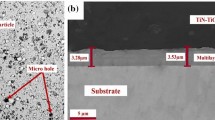

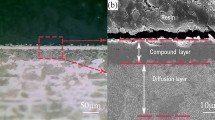

In this work, the dry sliding wear test of uncoated and multilayer TiCN-coated AISI 410 steel against high carbon steel disc recognized at 2.30267 ms−1 sliding speeds and under a three series load of 5, 10 and 20 N at room temperature. On account of the more coherent interface between TiCN and C probably found, there are high hardness and superior wear resistance. Compared to AISI 410 uncoated steel, the presence of C in the multilayer TiCN coatings leads to reduced coefficient of friction and wear loss. The multilayer TiCN coating is characterized by X-ray diffraction analysis, scanning electron microscopy, micro-hardness and pin-on-disc tribometer tests. The more grooving region, pits and ploughing ridge were examined on the worn surface of the AISI 410 uncoated steel. The result shows hard multilayer TiCN-coated particles viewing on the worn surface of the high carbon steel disc.

Similar content being viewed by others

Abbreviations

- V:

-

Voltage

- T:

-

Time in min

- L:

-

Load in N

- TiCN:

-

Titanium carbonitride

- COF:

-

Coefficient of friction

References

D.E. Richardson, Review of power cylinder friction for diesel engines, Internal Report, Cummins Engine Company

M. Nakada, Piston and piston ring tribology and fuel economy, in Proceedings of International Tribology Conference, Yokohama, 1995

L.L Ting, A review of present information on piston ring tribology, AE Paper 852355, 1985

S.B. Hill, B.A. Newman, Piston rings designs for reduced friction, SAE Paper 841222, 1984

L. Fedrizzi, S. Rossi, R. Cristel, P.L. Bonora, Elect. Chem. Acta 49, 2803–2814 (2004)

H. Singh, D. Puri, S. Prakash, Anti. Corros. Method Mater. 52(2), 84–95 (2005)

S.C. Tung, H. Gao, Tribological characteristic and surface interaction between piston ring coating and a blend of energy-conserving oils and ethanol fuels. Wear 255, 1276–1285 (2003)

C. Simon, Tung, modeling of abrasive wear in a piston ring and engine cylinder bore system. Tribol. Trans. 47, 17–22 (2004)

M. Arita, Recent trends on surface finishing of engine components. Tribology 36(7), 515–518 (1990)

N.G. Demas, R.A. Erck, O.O. Ajayi, G.R. Fenske, Tribological studies of coted piston sliding against cylinder liner under laboratory test conditions. Lubr. Sci. 24(5), 216–227 (2012)

C.H.O. Dae-Hyun, L.E.E. Young-Ze, Evaluating of ring surfaces with several coatings for friction, wear and scuffing life. Trans. Nonferrous Met. Soc. China 19, 992–996 (2009)

L.A. Dobrzanski, K. Lukaszkowicz, A. Zarychta, Mechanical properties of monolayer coatings deposited by PVD techniques. J. Achiev. Mater. Manuf. Eng. 20(1–2), 423–426 (2007)

Y. Armada, T. Aoki et al., Cutting performance of coated cemented carbide tools for hard work materials. Trans. JSME Ser. C 60(577), 2906–2910 (1994)

P. Steyer, C. Mendibide, J.P. Millet, H. Mazille, Improvement of high temperature corrosion resistance of tool steels by nanostructured PVD coating [J]. Mater. Sci. Forum 426, 2503–2508 (2003)

M. Merklein, T. Schrader, U. Engel, Wear behavior of PVD-coating. Tribol. Ind. 34(2), 51–56 (2012)

K. Khlifi, A. Ben Cheikh Larbi, Investigation of adhesion of PVD coatings using various approaches. Surf. Eng. 29(7), 555–560 (2013)

L. Zhua, Y. Zhanga, T. Hua, P. Leichtb, Y. Liub, Oxidation resistance and thermal stability of Ti(C, N) and Ti(C, N, O) coatings deposited by chemical vapor deposition. Int. J. Refract. Met. Hard Mater. 54, 295–303 (2016)

M.S. Priyan, P. Hariharan, Wear and corrosion resistance of Fe based coatings by HVOF sprayed on gray cast-iron for automotive application. Tribol Ind 36(4), 394–405 (2014)

S. Carvalho, L. Rebouta, A. Cavaleiro, L. Rocha, J. Gomez, E. Alves, Microstructure and mechanical properties of nanocomposite TiAlN coatings [J]. Thin Solid Films 398, 391–396 (2001)

F. Klocke, Manufacturing processes 1, cutting, RWTH series (Springer, New York, 2011), p. 504

J.C. Caicedo, C. Amaya, L. Yate, G. Zambrano, M.E. Gomez, J. Alvarado-Rivera, J. Munoz-Saldana, P. Prieto, TiCN/TiNbCN multilayer coatings with enhanced mechanical properties. Appl. Surf. Sci. 256, 5898–5904 (2010)

S. Bull, D. Bhat, M. Staia, Surf. Coat. Technol. 163, 499 (2003)

S. Surviliene, S. Bellozor, M. Kurtinaitiene, V. Safonov, Surf. Coat. Technol. 176, 193 (2004)

O.O. Ajayi, J.G. Hersgerger, J. Zhang, H. Yoon, G. Fenske, Microstructural evolution during scuffing of hardened 4340 steel—implication for scuffing mechanism [J]. Tribol. Int. 38, 277–282 (2005)

Y.Z. Lee, K.C. Ludema, The shared-load wear model in lubricated sliding: scuffing criteria and wear coefficients [J]. Wear 138, 13–22 (1990)

L.A. Dobrzanski, K. Lukaszkowiez, A. Zarychta, L. Cunha, J. Mater. Process. Technol. 164–165, 816–821 (2005)

L. Cunha, M. Andritschky, L. Rebouta, K. Pischow, Surf. Coat. Technol. 116–119, 1152–1160 (1999)

W. Schintlmeister, O. Pacher, J. Vac. Sci. Technol. 12, 743 (1975)

Y.H. Yoo, D.P. Le, J.G. Kim, S.K. Kim, P.V. Vinh, Thin Solid Films 516, 3544–3548 (2008)

X. Ding, A.L.K. Tan, X.T. Zeng, C. Wang, T. Yue, C.Q. Sun, Thin Solid Films 516, 5716–5720 (2008)

J.E. Kelley, J.J. Stiglich Jr., G.L. Sheldon, Methods of characterization of tribological properties of coatings. Surf. Mod. Tech., 169–187 (1988)

J.A. Williams, A.M. Hyncica, Mechanisms of abrasive wear in lubricated contacts. Wear 152(1), 57–74 (1992)

W.C. Oliver, G.M. Pharr, Improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7(6), 1564–1580 (1992)

L. Shan, Y. Wang, J. Li, H. Li, L.X. Wu, J. Chen, Tribological behaviors of PVD TiN and TiCN coatings in artificial seawater. Surf. Coat. Technol. 226, 40–50 (2013)

M.A. Chowdhury, D.M. Nuruzzaman, A.H. Mia, M.L. Rahaman, Friction coefficient of different material pairs under different normal loads and sliding velocities. Tribol. Ind 34(1), 18–23 (2012)

Acknowledgments

The authors would like to thank Oerlikon coating service Chennai to provide the different PVD coating. The authors would like to thanks to Dr. Jeppiaar, Chairman, Dr. N. Marie Wilson, Director and Dr. V. Kannan, Principal of Jeppiaar institute of technology, for their constant encouragement in all endeavors. The authors would also like to thank Dr. K. Pitchandi, Professor, Head of the Department, Mechanical Department, in Sri Venkateswara college of Engineeering, Sriperumbudur, Chennai, for their support toward the project. The authors are thankful to the reviewer for providing their useful comments, suggestions and guidelines during the course of revision to improve the technical quality of the present paper. The authors also wish to acknowledge the help of Research centre, Mechanical Department, Sri Venkateswara College of Engineering Pennalur, Sriperumbudur-602117, for supporting and the necessary facilities to carry out my research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prabakaran, V., Sivakumaran, I. & Palimar, S.P. Experimental investigation of wear characteristics on TiCN-coated AISI 410 steel. Appl. Phys. A 122, 468 (2016). https://doi.org/10.1007/s00339-016-9980-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-9980-3