Abstract

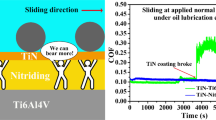

Sliding wear behavior of laser-nitrided and thermal oxidation-treated Ti–5Al–5Mo–5V–1Cr–1Fe (TC18) alloy fabricated by laser melting deposition (LMD) has been investigated to improve on wear resistance of laser melting deposited titanium alloy. The microstructure, wear morphology, hardness and wear rate were examined for the unmodified, laser-nitrided and thermal oxidation-treated LMD Ti–5Al–5Mo–5V–1Cr–1Fe alloy. As compared to α/β basket weave microstructure with fine lamellar α (hcp) observed on the unmodified LMD Ti–5Al–5Mo–5V–1Cr–1Fe alloy, Ti, Ti2N and TiN were formed on the LMD specimens after laser nitriding. After thermal oxidation, a surface layer composed of rutile TiO2 was formed on the LMD specimens along with coarsening of α lath. The increase in hardness and wear resistance of the laser-nitrided LMD Ti–5Al–5Mo–5V–1Cr–1Fe alloy is attributed to hard dendritic TiN formed on the specimens. The wear rate of the thermal oxidation-treated LMD specimens was <1 % of that of the unmodified LMD specimens when hardness of the former was twice as much as the latter. The superior sliding wear resistance of the thermal oxidation-treated LMD specimens is attributed to the presence of the lubricious rutile oxide layer and hardened diffusion zone.

Similar content being viewed by others

References

R.J. He, H.M. Wang, Mater. Sci. Eng. A Struct. 1933, 527 (2010)

E. Chlebus, B. Kuznicka, T. Kurzynowski, B. Dybala, Mater. Charact. 488, 62 (2011)

C.M. Liu, X.J. Tian, H.B. Tang, H.M. Wang, J. Alloys Compd. 17, 572 (2013)

L.L. Yu, X.N. Mao, P.S. Zhang, Y.Q. Zhao, S.C. Yuan, Rare Met. 21, 24 (2005)

A.M. Mubarak, S.G.S. Raman, S.D. Pathak, R. Gnanamoorthy, Tribol. Int. 152, 43 (2010)

P. Jiang, X.L. He, X.X. Li, L.G. Yu, H.M. Wang, Surf. Coat. Technol. 24, 130 (2000)

Md OhidulAlam, A.S.M.A. Haseeb, Tribol. Int. 357, 35 (2002)

S. Wang, Z.H. Liao, Y.H. Liu, W.Q. Liu, Surf. Coat. Technol. 64, 252 (2014)

H. Guleryuz, H. Cimenoglu, Surf. Coat. Technol. 164, 192 (2005)

S. Kumar, T.S.N.S. Narayanan, S.G.S. Raman, S.K. Seshadri, Mater. Chem. Phys. 337, 119 (2010)

L. Liu, Y.J. Shangguan, H.B. Tang, H.M. Wang, Appl. Phys. A 1993, 116 (2014)

A.R. Rastkar, T. Bell, Wear 1616, 258 (2005)

Acknowledgments

The research work is sponsored by Beijing Higher Education Young Elite Teacher Project, the State Key Basic Research Program of China (Grant No. 2010CB731705) and the State Key Basic Research Program of China (Grant No. 2011CB606305).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, L., Shangguan, Y.J., Li, H.Z. et al. Sliding wear behavior of laser-nitrided and thermal oxidation-treated Ti–5Al–5Mo–5V–1Cr–1Fe alloy fabricated by laser melting deposition. Appl. Phys. A 122, 477 (2016). https://doi.org/10.1007/s00339-016-0022-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0022-y