Abstract

Nanoimprint lithography (NIL) is an indispensable tool to realize a fast and accurate nanoscale patterning in nanophotonics due to high resolution and high yield. The number of publication on NIL has increased from less than a hundred per year to over three thousand per year. In this paper, the most recent developments on NIL patterning transfer processes and its applications on nanophotonics are discussed and reviewed. NIL has been opening up new opportunities for nanophotonics, especially in fabricating optical meta-materials. With more researches on this low-cost high-throughput fabrication technology, we should anticipate a brighter future for nanophotonics and NIL.

Similar content being viewed by others

References

F. Flory, L. Escoubas, G. Berginc, Optical properties of nanostructured materials: a review. J. Nanophotonics 5(1), 052502–0525020 (2011)

S.Y. Chou, P.R. Krauss, P.J. Renstrom, Imprint of sub-25 nm vias and trenches in polymers. Appl. Phys. Lett. 67(21), 3114–3116 (1995)

S.Y. Chou, P.R. Krauss, P.J. Renstrom, Nanoimprint lithography. J. Vac. Sci. Technol. B 14(6), 4129–4133 (1996)

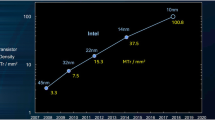

Hoefflinger, B., ITRS: The International Technology Roadmap for Semiconductors, in Chips 2020, ed by B. Hoefflinger, (Springer, Berlin, Heidelberg, 2012). pp. 161–174

M.D. Levenson, N. Viswanathan, R.A. Simpson, Improving resolution in photolithography with a phase-shifting mask. IEEE Electron Devices Trans. 29(12), 1828–1836 (1982)

C. Vieu et al., Electron beam lithography: resolution limits and applications. Appl. Surf. Sci. 164(1), 111–117 (2000)

I. Divliansky et al., Fabrication of three-dimensional polymer photonic crystal structures using single diffraction element interference lithography. Appl. Phys. Lett. 82(11), 1667–1669 (2003)

H.X. Ge et al., Cross-linked polymer replica of a nanoimprint mold at 30 nm half-pitch. Nano Lett. 5(1), 179–182 (2005)

Y.-P. Chen et al., Fabrication of concave gratings by curved surface UV-nanoimprint lithography. J. Vac. Sci. Technol. B 26(5), 1690–1695 (2008)

Z. Li et al., Hybrid nanoimprint—soft lithography with sub-15 nm resolution. Nano Lett. 9(6), 2306–2310 (2009)

M. Colburn et al., Proc. SPIE 3676, 379–389 (1999)

J. Haisma et al., Mold-assisted nanolithography: a process for reliable pattern replication. J. Vac. Sci. Technol. B 14(6), 4124–4128 (1996)

Z. Yu et al., Fabrication of nanoscale gratings with reduced line edge roughness using nanoimprint lithography. J. Vac. Sci. Technol. B 21(5), 2089–2092 (2003)

Chou, S., Z. Yu, W. Wu, Articles comprising nanoscale patterns with reduced edge roughness and methods of making same, 2003, US Patent App. 10/732,038

Yao, Y., et al., Line width tuning and smoothening for periodical grating fabrication in nanoimprint lithography. Appl. Phys. A, 1–5 (2015). doi:10.1007/s00339-015-9278-x

R.A. Wind, M.A. Hines, Macroscopic etch anisotropies and microscopic reaction mechanisms: a micromachined structure for the rapid assay of etchant anisotropy. Surf. Sci. 460(1), 21–38 (2000)

F. Meng et al., Replication of large area nanoimprint stamp with small critical dimension loss. Sci. China Technol. Sci. 55(3), 600–605 (2012)

S.M. Spillane et al., Fabrication of nanophotonic structures for information processing. In: Proceedings of the SPIE 6883, Advanced Fabrication Technologies for Micro/Nano Optics and Photonics, 688302 (2008)

H. Tan, A. Gilbertson, S.Y. Chou, Roller nanoimprint lithography. J. Vac. Sci. Technol. B 16(6), 3926–3928 (1998)

S.H. Ahn, L.J. Guo, Large-area roll-to-roll and roll-to-plate nanoimprint lithography: a step toward high-throughput application of continuous nanoimprinting. ACS Nano 3(8), 2304–2310 (2009)

N.I. Zheludev, The road ahead for metamaterials. Science 328(5978), 582–583 (2010)

V.G. Veselago, The electrodynamics of substances with simultaneously negative values of ɛ and μ. Sov. Phys. Usp. 10(4), 509–514 (1968)

D.R. Smith et al., Composite medium with simultaneously negative permeability and permittivity. Phys. Rev. Lett. 84(18), 4184–4187 (2000)

R.A. Shelby, D.R. Smith, S. Schultz, Experimental verification of a negative index of refraction. Science 292(5514), 77–79 (2001)

V.M. Shalaev et al., Negative index of refraction in optical metamaterials. Opt. Lett. 30(24), 3356–3358 (2005)

S. Zhang et al., Near-infrared double negative metamaterials. Opt. Express 13(13), 4922–4930 (2005)

S. Zhang et al., Experimental demonstration of near-infrared negative-index metamaterials. Phys. Rev. Lett. 95(13), 137404 (2005)

G. Dolling et al., Simultaneous negative phase and group velocity of light in a metamaterial. Science 312(5775), 892–894 (2006)

W. Wu et al., Midinfrared metamaterials fabricated by nanoimprint lithography. Appl. Phys. Lett. 90(6), 063107 (2007)

W. Wu et al., Optical metamaterials at near and mid-IR range fabricated by nanoimprint lithography. Appl. Phys. Mater. Sci. Process. 87(2), 143–150 (2007)

W. Wu et al., Geometrical dependence of optical negative index meta-materials at 1.55 μm. Appl. Phys. A 95(4), 1119–1122 (2009)

E. Kim et al., Modulation of negative index metamaterials in the near-IR range. Appl. Phys. Lett. 91(17), 173105 (2007)

D.J. Cho et al., Ultrafast modulation of optical metamaterials. Opt. Express 17(20), 17652–17657 (2009)

E. Kim et al., Nonlinear optical spectroscopy of photonic metamaterials. Phys. Rev. B (Condens. Matter Mater. Phys.) 78(11), 113102 (2008)

Y. Yao, H. Liu, W. Wu, Spectrum splitting using multi-layer dielectric meta-surfaces for efficient solar energy harvesting. Appl. Phys. A 115(3), 713–719 (2014)

Y. Yao, H. Liu, W. Wu, Fabrication of high-contrast gratings for a parallel spectrum splitting dispersive element in a concentrated photovoltaic system. J. Vac. Sci. Technol. B 32(6), 6 (2014)

W. Shockley, H.J. Queisser, Detailed balance limit of efficiency of p-n junction solar cells. J. Appl. Phys. 32(3), 510–519 (1961)

V. Karagodsky, F.G. Sedgwick, C.J. Chang-Hasnain, Theoretical analysis of subwavelength high contrast grating reflectors. Opt. Express 18(16), 16973–16988 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yao, Y., Liu, H., Wang, Y. et al. Nanoimprint lithography: an enabling technology for nanophotonics. Appl. Phys. A 121, 327–333 (2015). https://doi.org/10.1007/s00339-015-9438-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-015-9438-z