Abstract

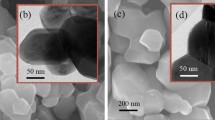

Co3Fe7@C core–shell nanoparticles with high performance of microwave-absorbing properties were prepared by hydrothermal method and heat treatment. The transformation of structural, morphological and magnetic properties among the carbon-encapsulated composites, which were annealed at three different temperatures, were investigated by X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), transmission electron microscopy (TEM) and vibrating sample magnetometer (VSM). XRD analysis indicated the phase composition of Co3Fe7/CoFe2O4, Fe3C/Co3Fe7 and pure Co3Fe7 at different annealing temperatures. TEM confirmed the Co3Fe7@graphite core–shell nanostructure with an average particle size of 180 nm. The saturation magnetization (M s) increased monotonically with the increase in temperature, which was attributed to the crystal growth and purity of metallic core. Co3Fe7@graphite nanoparticles exhibited the hysteretic loops of soft ferromagnetic behavior with high M s of 222.85 emu g−1, weak remanent magnetization (M r) and coercivity (H c). For Co3Fe7@graphite nanomaterial, a reflection loss exceeding −20 dB was obtained between 2.8 and 10.2 GHz, which almost covering from S-band to X-band. The maximum reflection loss is −26.8 dB at 9 GHz with 1.8 mm thickness. The excellent microwave absorption properties result from the proper electromagnetic match in core–shell nanostructure and the strong natural ferromagnetic resonance.

Similar content being viewed by others

References

S.S.S. Afghahi, A. Shokuhfar, J. Magn. Magn. Mater. 370, 37 (2014)

Z. Han, D. Li, H. Wang et al., Appl. Phys. Lett. 95, 023114 (2009)

X.F. Zhang, X.L. Dong, H. Huang et al., Appl. Phys. Lett. 89, 053115 (2006)

W.S. Seo, J.H. Lee, X. Sun et al., Nat. Mater. 5, 971 (2006)

C. Sun, J.S.H. Lee, M. Zhang, Adv. Drug. Deliver. Rev. 60, 1252 (2008)

X. Liu, S.W. Or, S.L. Ho et al., J. Alloy. Compd. 509, 9071 (2011)

X.G. Liu, Z.Q. Ou, D.Y. Geng et al., Carbon 48, 891 (2010)

K.E. Neo, Y.Y. Ong, H.V. Huynh et al., J. Mater. Chem. 17, 1002 (2007)

M.H. Teng, S.W. Tsai, C.I. Hsiao et al., J. Alloy. Compd. 434, 678 (2007)

A. Ebara, K. Kuramochi, T. Yamazaki et al., Carbon 45, 898 (2007)

Z.H. Wang, Z.D. Zhang, C.J. Choi et al., J. Alloy. Compd. 361, 289 (2003)

A.A. El-Gendy, E.M.M. Ibrahim, V.O. Khavrus et al., Carbon 47, 2821 (2009)

J.N. Wang, L.I. Zhang, F. Yu et al., J. Phys. Chem. B 111, 2119 (2007)

J.B. Park, S.H. Jeong, M.S. Jeong, Carbon 46, 1369 (2008)

C. Cao, Z. Ma, C. Ma et al., Mater. Lett. 88, 61 (2012)

M. Bystrzejewski, M. Arulepp, J. Leis, Mater. Lett. 63, 1435 (2009)

W. Wu, Z. Zhu, Z. Liu, Carbon 41, 317 (2003)

U. Narkiewicz, M. Podsiadły, R. Jędrzejewski, Appl. Catal. A-Gen. 384, 27 (2010)

Y. Xiong, J. Ye, X. Gu, J. Magn. Magn. Mater. 320, 107 (2008)

W. Li, X. Qiao, Q. Zheng et al., J. Alloy. Compd. 509, 6206 (2011)

S.R. Dhakate, R.B. Mathur, O.P. Bahl, Carbon 35, 1753 (1997)

C. Julien, M. Massot, C. Pérez-Vicente, Mater. Sci. Eng. B 75, 6 (2000)

R.D. Waldron, Phys. Rev. 99, 1727 (1995)

H.J. Grabke, Carburization: A High Temperature Corrosion Phenomenon (Elsevier, Amsterdam, 1998)

V. Raghavan, G.V. Raynor, V.G. Rivlin, Phase Diagrams of Ternary Iron Alloys (Indian Institute of Metals, Calcutta, 1987)

T.Y. Kosolapova, Carbides: Properties, Production, and Applications, 3rd edn. (Plenum Press, New York, 1971)

E. Pippel, J. Woltersdorf, H.J. Grabke, Mater. Corros. 54, 747 (2003)

E. Pippel, J. Woltersdorf, R. Schneider, Mater. Corros. 49, 309 (1998)

H.J. Grabke, Mater. Corros. 49, 303 (1998)

S. Tomita, M. Hikita, M. Fujii, Chem. Phys. Lett. 316, 361 (2000)

A. Tsuzuki, S. Sago, S.I. Hirano et al., J. Mater. Sci. 19, 251 (1984)

X.G. Liu, D.Y. Geng, J. Du, Scr. Mater. 59, 340 (2008)

C.Q. Sun, Prog. Solid State Chem. 35, 1 (2007)

X.G. Liu, D.Y. Geng, H. Meng, J. Appl. Phys. 41, 175001 (2008)

T. Sourmail, Prog. Mater Sci. 50, 816 (2005)

Z.B. Li, Y.D. Deng, B. Shen et al., J. Phys. D Appl. Phys. 42, 145002 (2009)

X.Q. Shen, F.Z. Song, Y. Chen et al., J. Compos. Mater. 46, 71 (2011)

M.J. Pierre, A. Oliver, Appl. Phys. Lett. 80, 4404 (1996)

T. Sourmail, Prog. Mater. Sci. 50, 816 (2005)

T. Wang, H. Wang, X. Chi et al., Carbon 74, 312 (2014)

C. Kittel, Phys. Rev. 73, 155 (1948)

Y. Naito, K. Suetake, IEEE Trans Microw Theory 19, 65 (1971)

W.L. Zuo, L. Qiao, X. Chi et al., J. Alloy. Compd. 509, 6359 (2011)

Acknowledgments

The work is supported by the State Key Laboratory of Explosion Science and Technology, BIT, PR China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, X.D., Qiao, X.J., Ren, Q.G. et al. Synthesis and microwave-absorbing properties of Co3Fe7@C core–shell nanostructure. Appl. Phys. A 120, 43–52 (2015). https://doi.org/10.1007/s00339-015-9164-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-015-9164-6